80 HyPrecision 50S/60S/75S Operator Manual 808690

5 – Preventive maintenance

Preventive maintenance

Check the hydraulic fluid quality

Contact a hydraulic fluid supplier for a precise report on the hydraulic fluid quality.

Do this task when the pump is not running.

1. Make sure that the drain valve is closed.

2. Look through the sight gauge to see the color of the hydraulic fluid. Good hydraulic fluid is almost

transparent.

3. Remove the filler-breather cap on top of the tank.

4. Smell the hydraulic fluid. Good hydraulic fluid has almost no odor.

Refer to page 84 for instructions for replacing the hydraulic fluid.

DANGER

People who maintain and repair this equipment can be injured or killed if hazardous energy is not

properly controlled. Injuries can include burns, cuts, fractures, or electrocution.

Turn off electrical power and relieve all water and hydraulic pressure from the pump before starting

maintenance or repairs.

Disconnect and lock out or tag out the electrical main before opening the electrical enclosure or

doing maintenance or repair procedures. Refer to page 97 for additional information.

DANGER

People who work on deenergized machinery can be seriously injured or killed if someone removes

lock-out or tag-out devices and reenergizes machinery without their knowledge. All workers must

respect lock-out and tag-out devices and that only the person(s) who applied these devices remove

them.

Service Interval

Check the hydraulic fluid quality Before every work shift

Replace the hydraulic fluid, the hydraulic filter, the

filler-breather cap, and the suction strainers

• If it is dark or milky in color

• If it has a strong odor

• After every 3,000 hours of operation

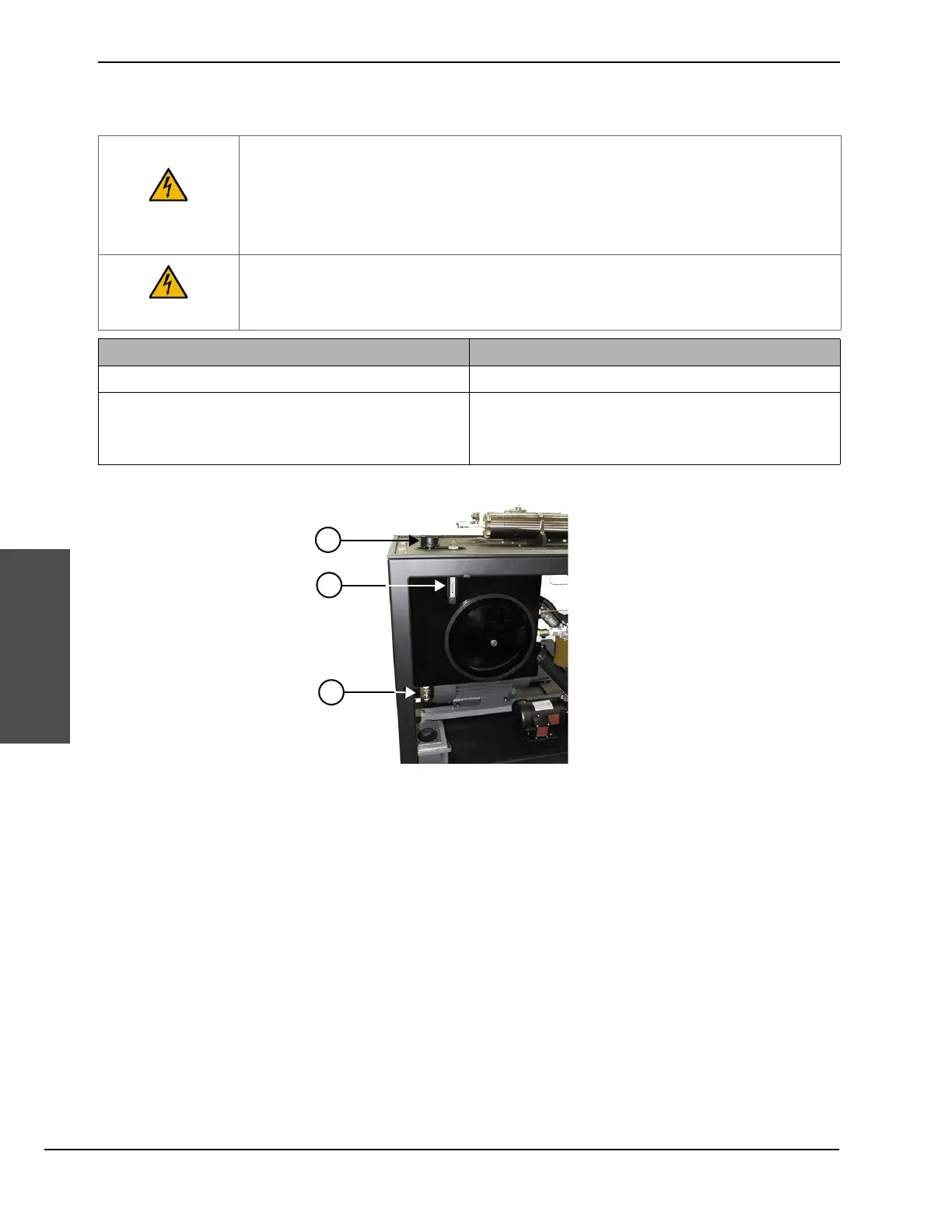

1 Filler-breather cap

2 Sight gauge

3 Drain valve

Loading...

Loading...