76 HyPrecision 50S/60S/75S Operator Manual 808690

5 – Preventive maintenance

Preventive maintenance

Electrical system

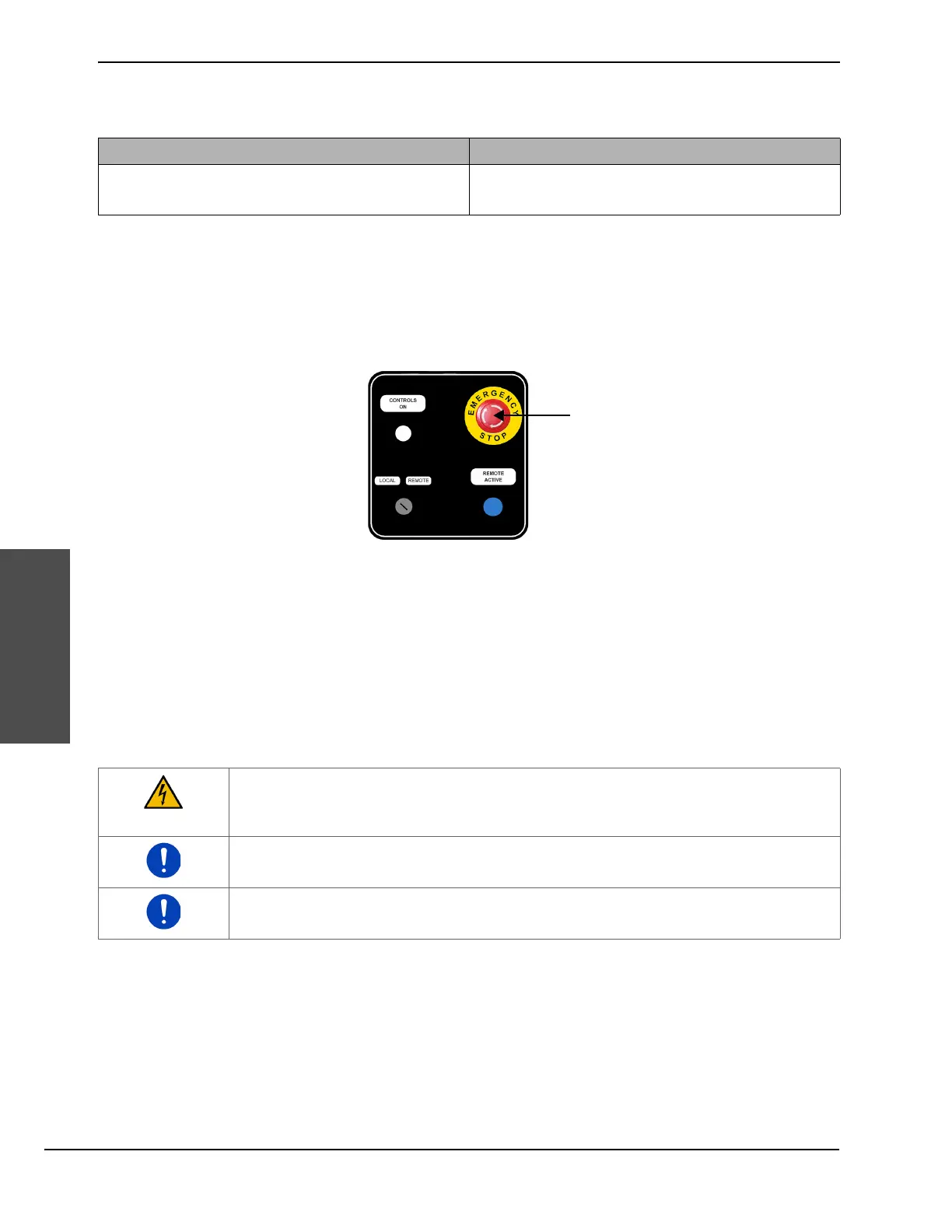

Make sure that the emergency stop button works

If the pump is set up to run remotely and has a motion system (robot or cutting table), the emergency circuits

from the robot or cutting table can be wired in series with the local emergency stop circuit.

The EMERGENCY STOP button is available on the operation panel.

Do this task when the pump is running.

Push the EMERGENCY STOP button.

The control circuit turns off, which turns off the pump, the primary motor, and the intensifier.

The bleed-down valve opens and discharges water from the system.

The CONTROLS ON button indicator light turns off.

Examine cords and plugs for deterioration or damage

Do this task when the pump is not running.

1. Examine electrical cords for kinks or damage to the insulation.

2. Examine electrical plugs and other electrical connectors for corrosion or damage.

Service Interval

Make sure that the emergency stop button works

Examine cords and plugs for deterioration or damage

Before every work shift

DANGER

Dangerous voltage

To reduce the risk of serious injuries or death, wear approved protection and follow safety

recommendations when working with electricity.

When replacing wiring, use only the same size, type, and color as the original wiring.

Repair or replace parts identified in the preventive maintenance schedule or if the parts show

deterioration, corrosion, or damage.

Loading...

Loading...