HyPrecision 50S/60S/75S Operator Manual 808690 107

5 – Preventive maintenance

Preventive maintenance

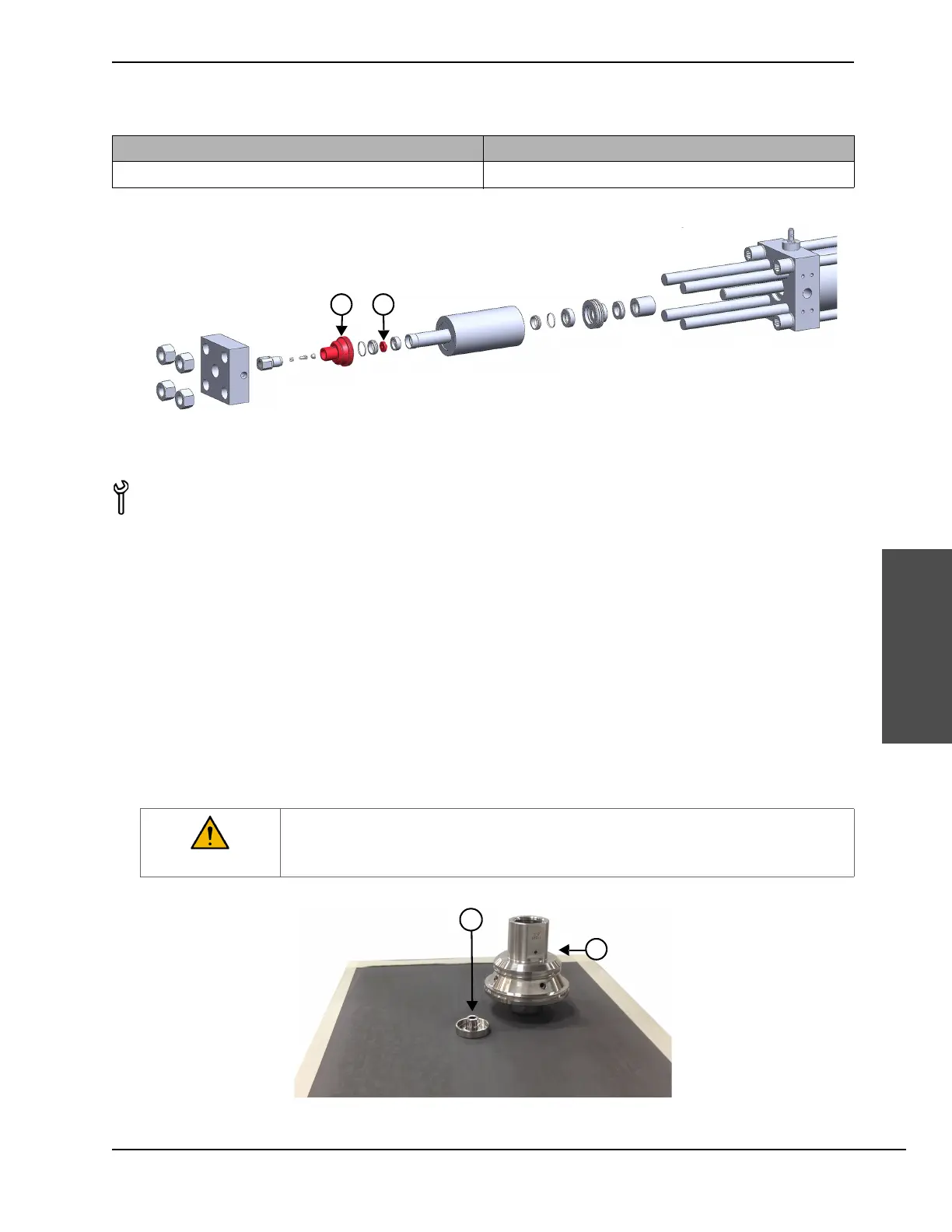

Repair the check valves and the low-pressure poppets

This procedure is for a moderately worn check valve. Severe wear requires replacement.

Required parts, tools, and materials

12-micron lapping paper (included in the 12084 HyPrecision standard tool kit)

15-micron lapping paper (included in the 12084 HyPrecision standard tool kit)

Granite surface plate (included in the 12084 HyPrecision standard tool kit)

Clean, lint-free towels

Isopropyl alcohol

Masking tape

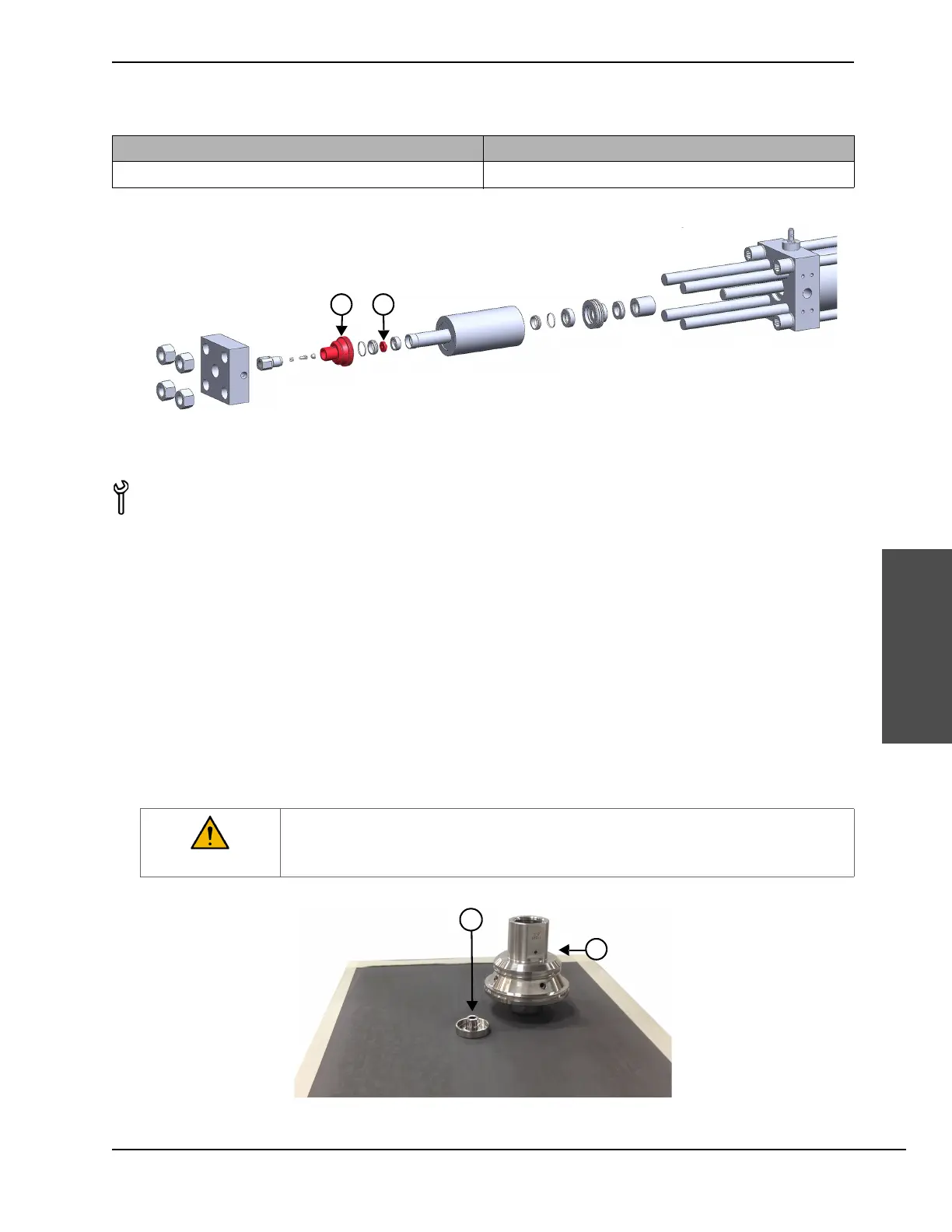

1. Tape a sheet of lapping paper on a granite surface block. Make sure that the paper is smooth and flat.

For best results, start with the 12-micron lapping paper and finish with the 15-micron lapping paper.

2. Put the check valve or poppet face flat on the lapping paper and slide it back and forth. Apply light pressure.

Service Interval

Repair the check valves and the low-pressure poppets After every 500 hours of operation

CAUTION

Rocking the part or using too much pressure can damage the part face.

1 Check valve 2 Low-pressure poppet

Loading...

Loading...