Operation

38

Figure 5.3 Quick testing.diagram

6. DETAILED FUNCTION DESCRIPTION

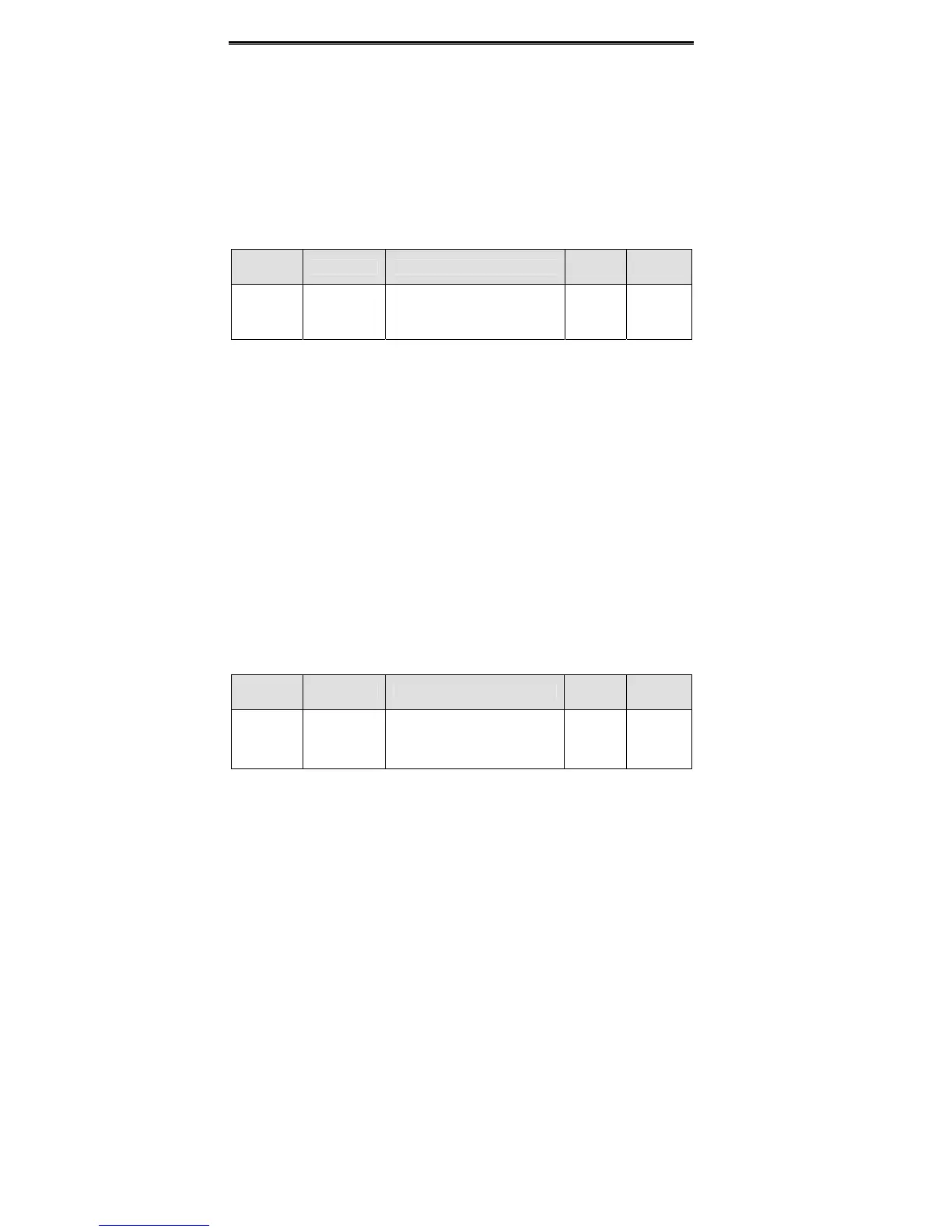

6.1 P0 Group--Basic Function

Function

Code

Name Description

Setting

Range

Factory

Setting

P0.00

Control

mode

selection

0:Sensorless vector control

1:V/F control

2:Torque control

0~2 0

0: Sensorless vector control: It is widely used for the application which requires high

torque at low speed, higher speed accuracy, and quicker dynamic response, such as

machine tool, injection molding machine, centrifugal machine and wire-drawing machine,

etc.

1: V/F control: It is suitable for general purpose application such as pumps, fans etc.

2: Torque control: It is suitable for the application with low accuracy torque control, such

as wired-drawing. In torque control mode, the speed of motor is determined by load, the

rate of ACC/DEC has nothing to do with the value of P0.08 and P0.09 (or P8.00 and

P8.01).

Notice:

z Inverter can drive only one motor when P0.00 is set to be 0 or 2. When P0.00

is set to be 1, inverter can drive multi motors.

z The autotuning of motor parameters must be accomplished properly when

P0.00 is set to be 0 or 2.

z In order to achieve better control characteristic, the parameters of speed

regulator (P3.00~P3.05) must be adjusted according to actual situation when

P0.00 is set to be 0 or 2.

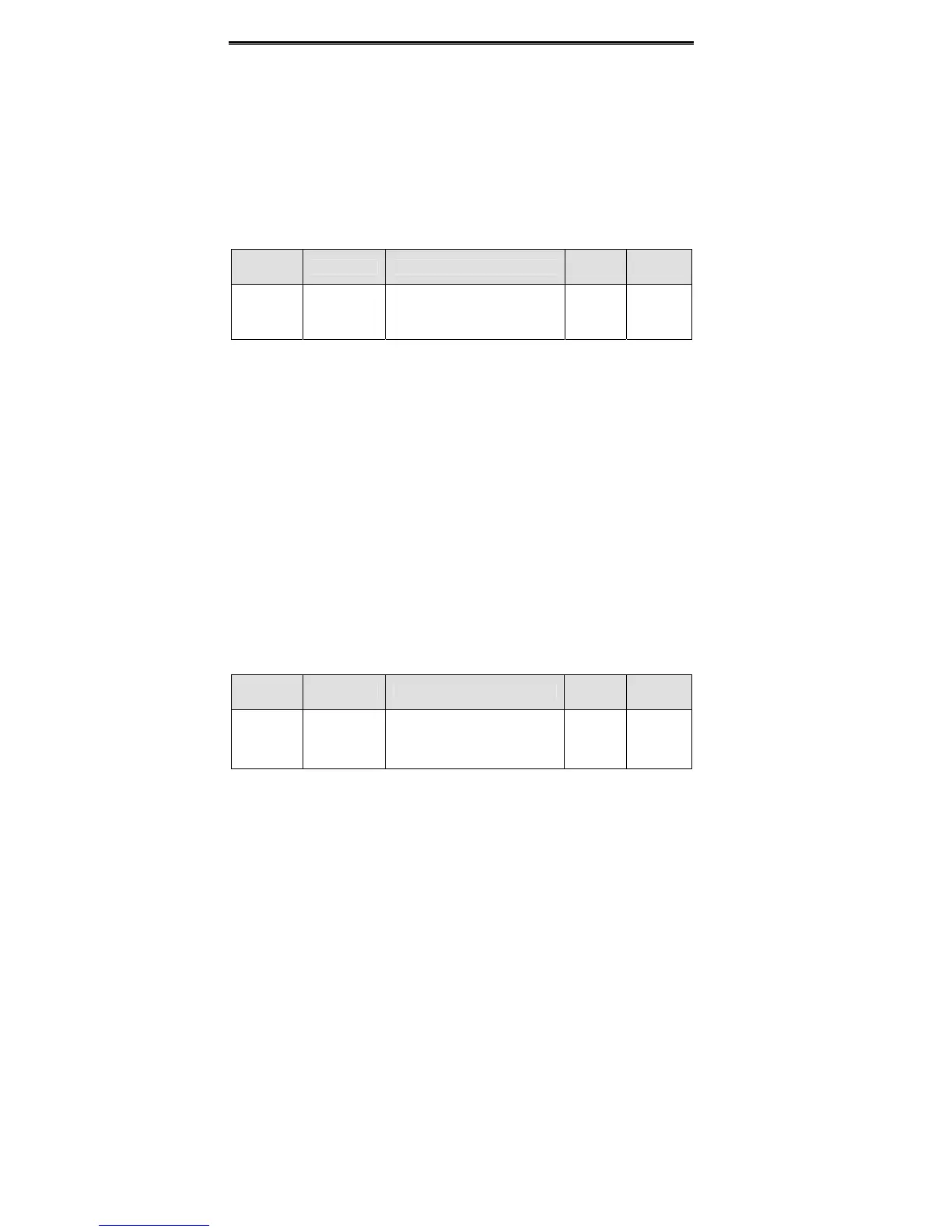

Function

Code

Name Description

Setting

Range

Factory

Setting

P0.01

Run

command

source

0: Keypad (LED extinguished)

1: Terminal (LED flickering)

2: Communication (LED lights

on)

0~2 0

The control commands of inverter include: start, stop, forward run, reverse run, jog, fault

Loading...

Loading...