Detailed Function Description

69

Function

Code

Name Description

Setting

Range

Factory

Setting

P9.03

PID output

characteristics

0: Positive

1: Negative

0~1 0

0:Positive. When the feedback value is greater than the preset value, output frequency

will be decreased, such as tension control in winding application.

1: Negative. When the feedback value is greater than the preset value, output frequency

will be increased, such as tension control in unwinding application.

Function

Code

Name Description Setting Range

Factory

Setting

P9.04 Proportional gain (Kp) 0.00~100.00 0.00~100.00 0.10

P9.05 Integral time (Ti) 0.01~10.00s 0.01~10.00 0.10s

P9.06 Differential time (Td) 0.00~10.00s 0.00~10.00 0.00s

Optimize the responsiveness by adjusting these parameters while driving an actual load.

Use the following procedure to activate PID control and then adjust it while monitoring the

response.

1. Enabled PID control (P0.03=5)

2. Increase the proportional gain (Kp) as far as possible without creating oscillation.

3. Reduce the integral time (Ti) as far as possible without creating oscillation.

4. Increase the differential time (Td) as far as possible without creating oscillation.

Making fine adjustments:

First set the individual PID control constants, and then make fine adjustments.

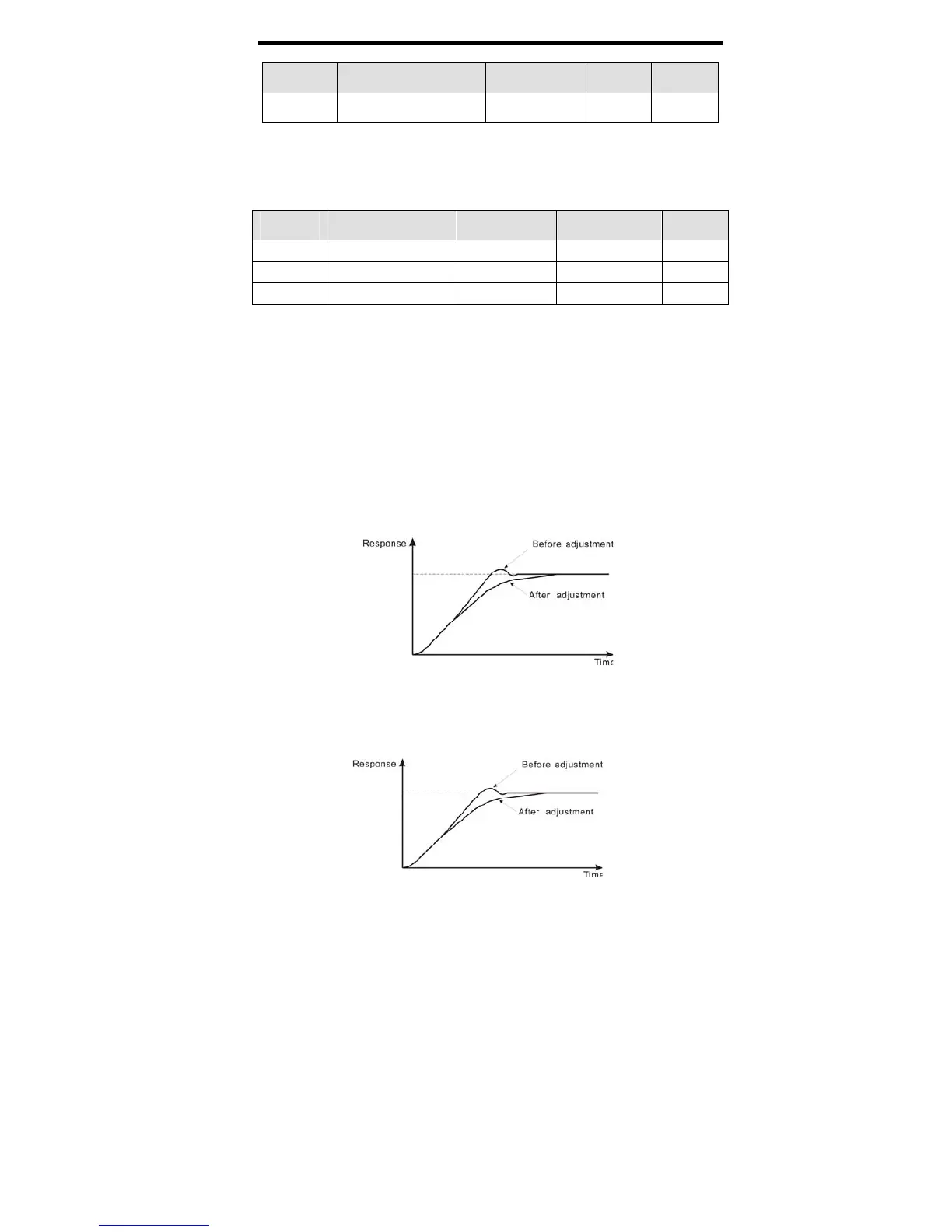

z Reducing overshooting

If overshooting occurs, shorten the differential time and lengthen the integral time.

Figure 6.21 Reducing overshooting diagram.

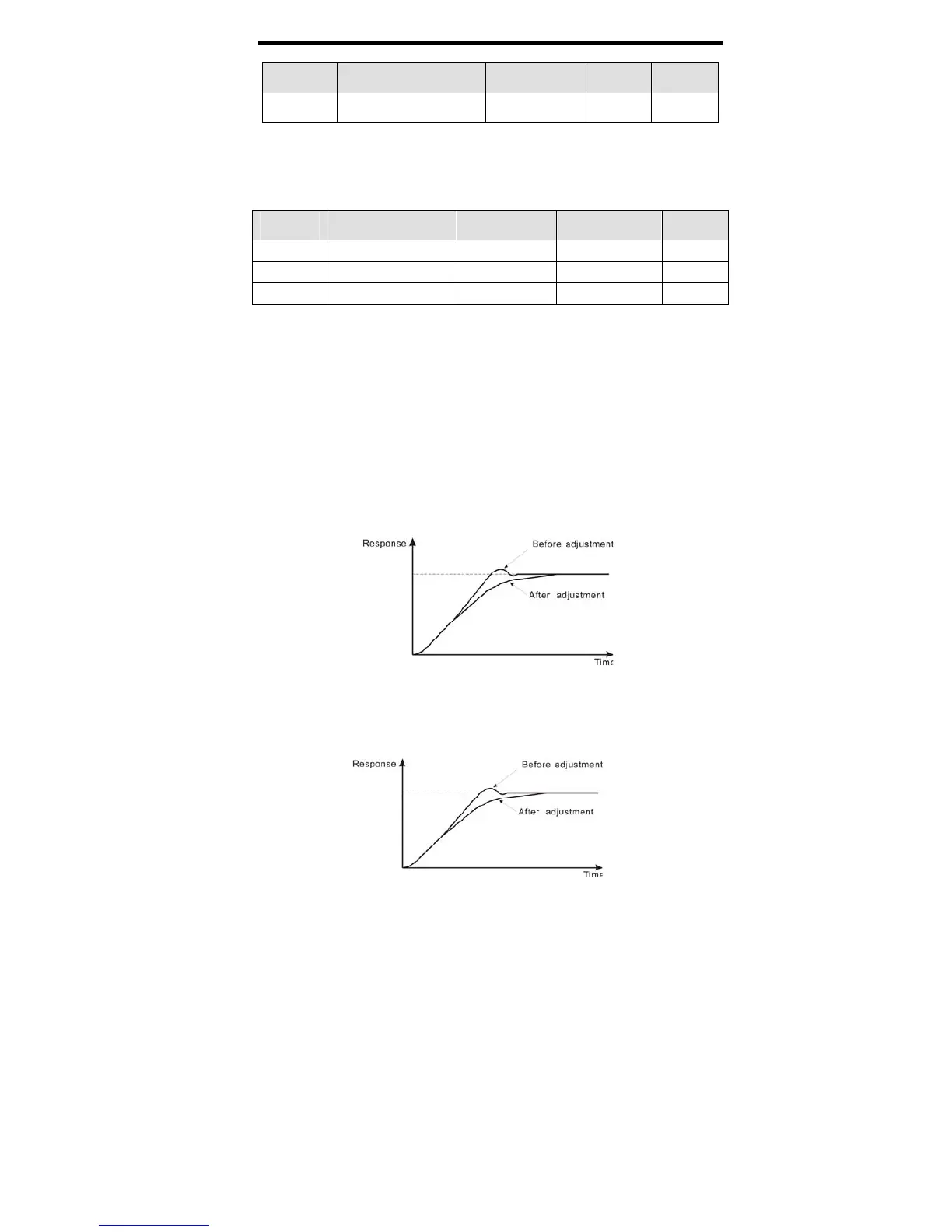

z Rapidly stabilizing control status

To rapidly stabilize the control conditions even when overshooting occurs, shorten the

integral time and lengthen the differential time.

Loading...

Loading...