Maintenance

85

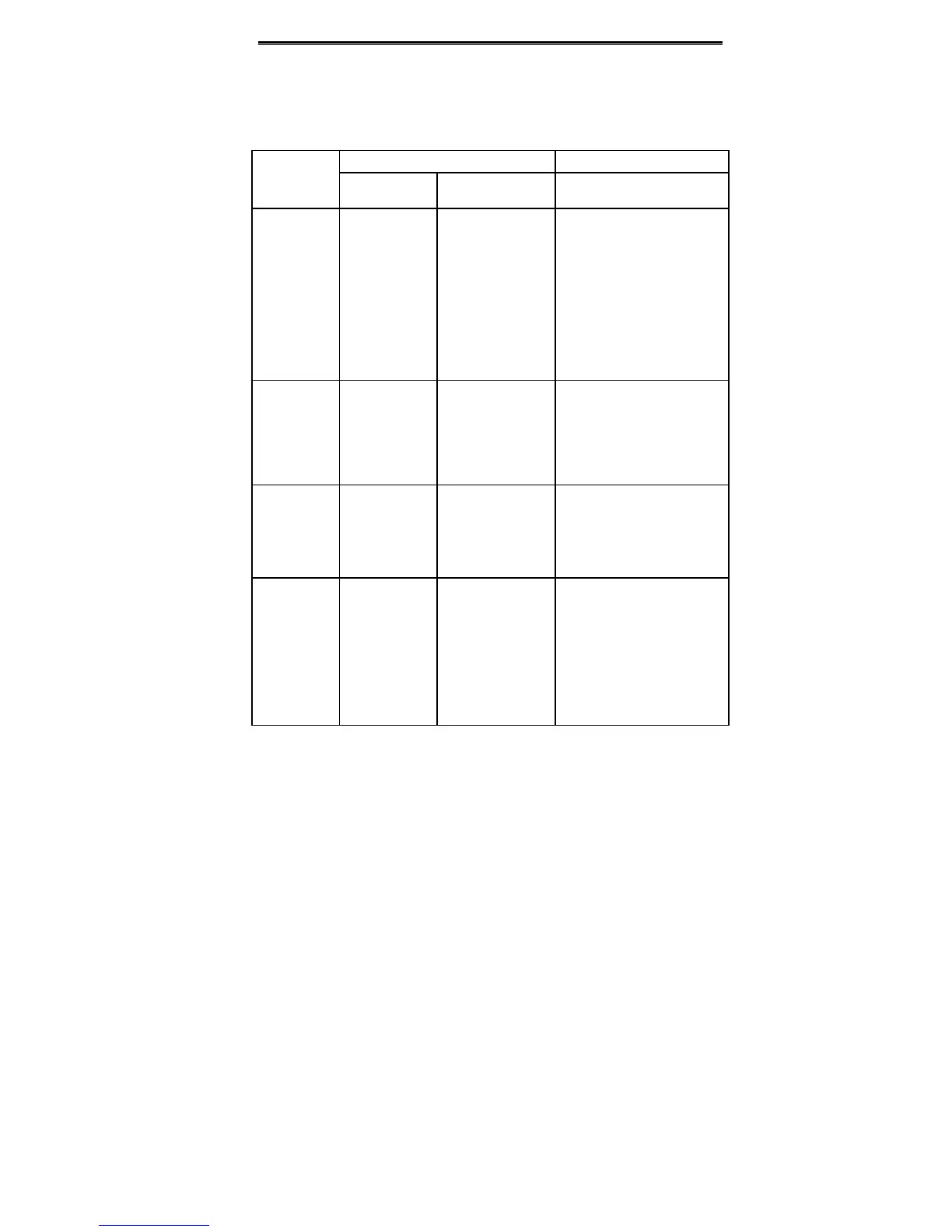

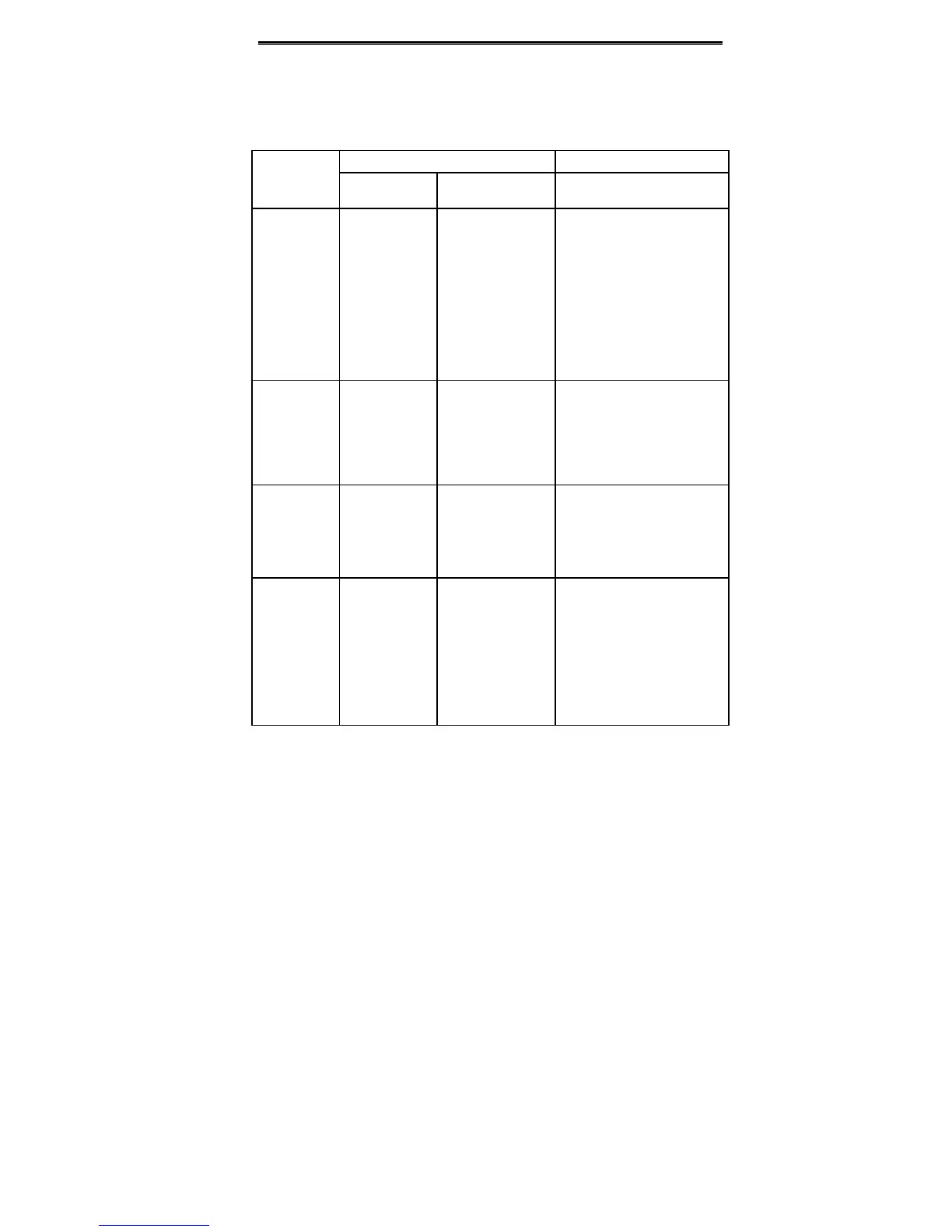

8.1 Daily Maintenance

In order to prevent the fault of inverter to make it operate smoothly in high-performance

for a long time, user must inspect the inverter periodically (within half year). The following

table indicates the inspection content.

Main inspections Criteria

Items to be

checked

Inspection

content

Frequency Means/methods

Operation

environment

1. temperature

2. humidity

3. dust

4. vapor

5. gases

1. point

thermometer,

hygrometer

2. observation

3. visual

examination and

smelling

1. ambient temperature shall

be lower than 40 , otherwise, ℃

the rated values should be

decreased. Humidity shall

meet the requirement

2. no dust accumulation, no

traces of water leakage and

no condensate.

3. no abnormal color and

smell.

Inverter

1. vibration

2. cooling and

heating

3. noise

1. point

thermometer

2. comprehensive

observation

3. listening

1. smooth operation without

vibration.

2. fan is working in good

condition. Speed and air flow

are normal. No abnormal heat.

3. No abnormal noise

Motor

1. vibration

2. heat

3. noise

1. comprehensive

observation

2. point

thermometer

3. listening

1. No abnormal vibration and

no abnormal noise.

2. No abnormal heat.

3. No abnormal noise.

Operation

status

parameters

1. power input

voltage

2. inverter

output voltage

3. inverter

output current

4. internal

temperature

1. voltmeter

2. rectifying

voltmeter

3. ammeter

4. point

thermometer

1. satisfying the specification

2. satisfying the specification

3. satisfying the specification

4. temperature rise is lower

than 40 ℃

8.2 Periodic Maintenance

Customer should check the drive every 3 months or 6 months according to the actual

Loading...

Loading...