Detailed Function Description

68

This parameter is used to calibrate the bias between actual mechanical speed and

rotation speed. The formula is as below:

Actual mechanical speed = 120 * output frequency *P8.17 / Number of poles of motor

6.10 P9 Group--PID Control

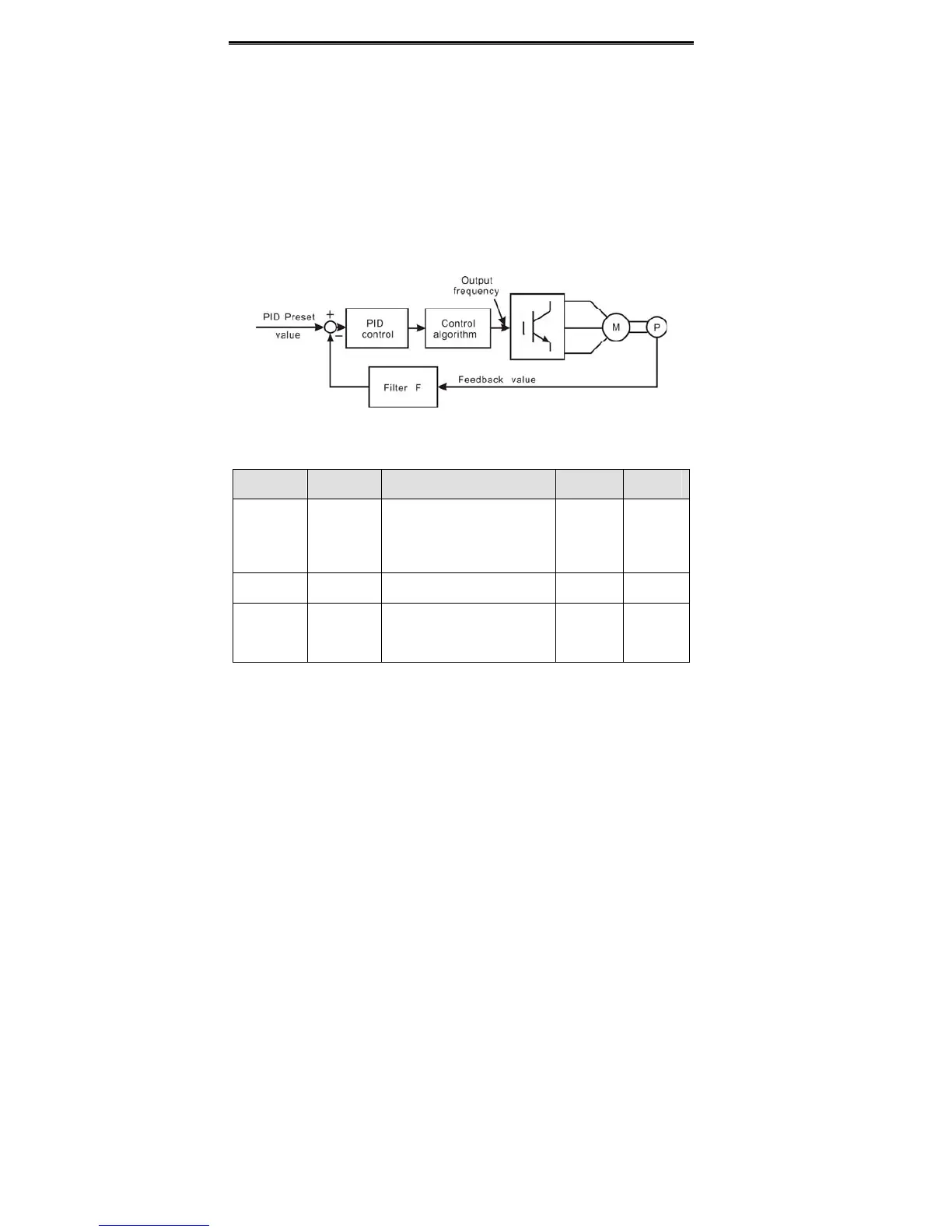

PID control is a common used method in process control, such as flow, pressure and

temperature control. The principle is firstly detect the bias between preset value and

feedback value, then calculate output frequency of inverter according to proportional gain,

integral and differential time. Please refer to following figure.

Figure 6.20 PID control diagram.

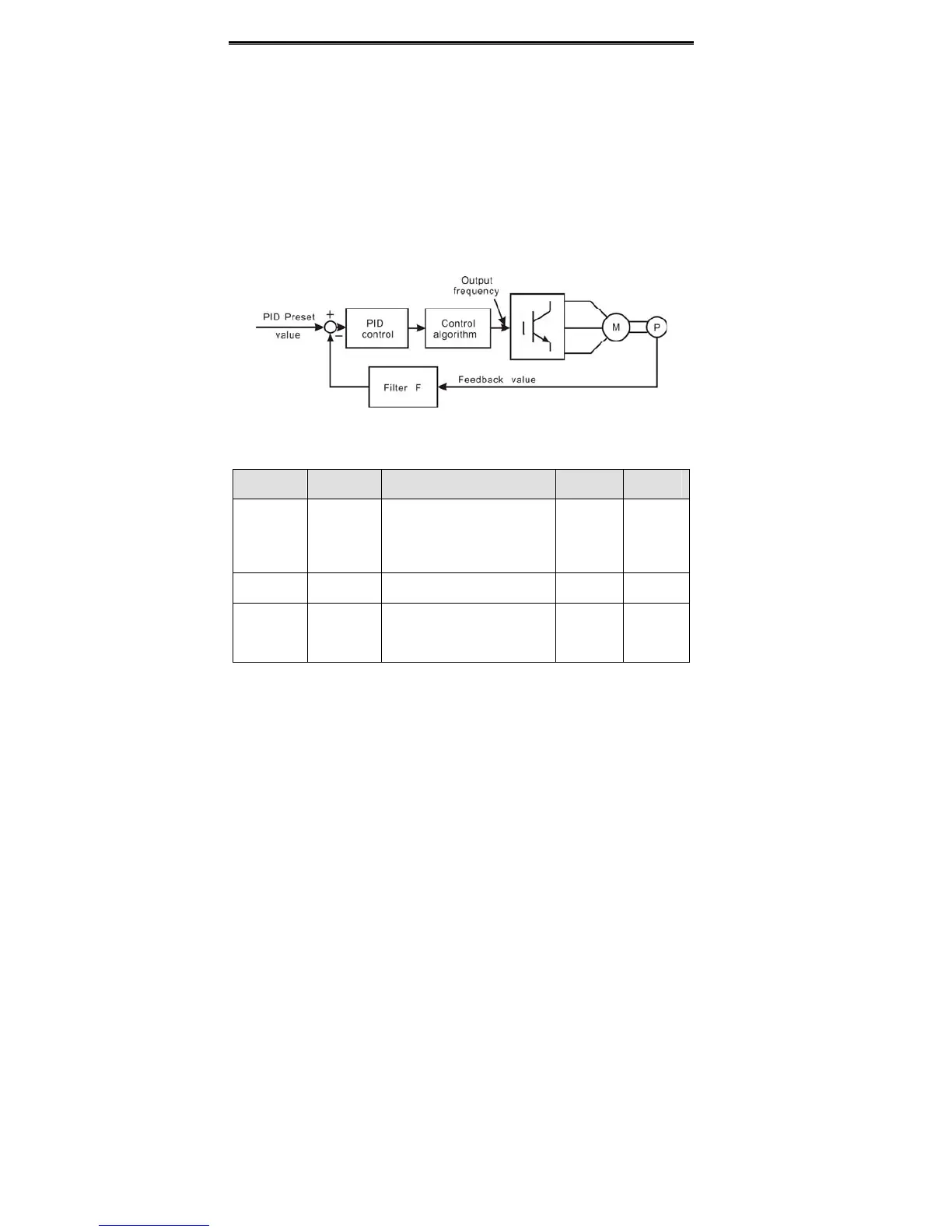

Function

Code

Name Description

Setting

Range

Factory

Setting

P9.00

PID preset

source

selection

0: Keypad

1: AI1

2: AI2

3: Communication

4: Multi-step

0~4 0

P9.01

Keypad

PID preset

0.0%~100.0% 0.0~100.0 0.0%

P9.02

PID

feedback

source

selection

0: AI1

1: AI2

2: AI1+AI2

3: Communication

0~3 0

These parameters are used to select PID preset and feedback source.

Notice:

Preset value and feedback value of PID are percentage value.

100% of preset value is corresponding to 100% of feedback value.

Preset source and feedback source must not be same, otherwise PID will be

malfunction.

Loading...

Loading...