SV-DA200 series AC servo drives Communication

‐228‐

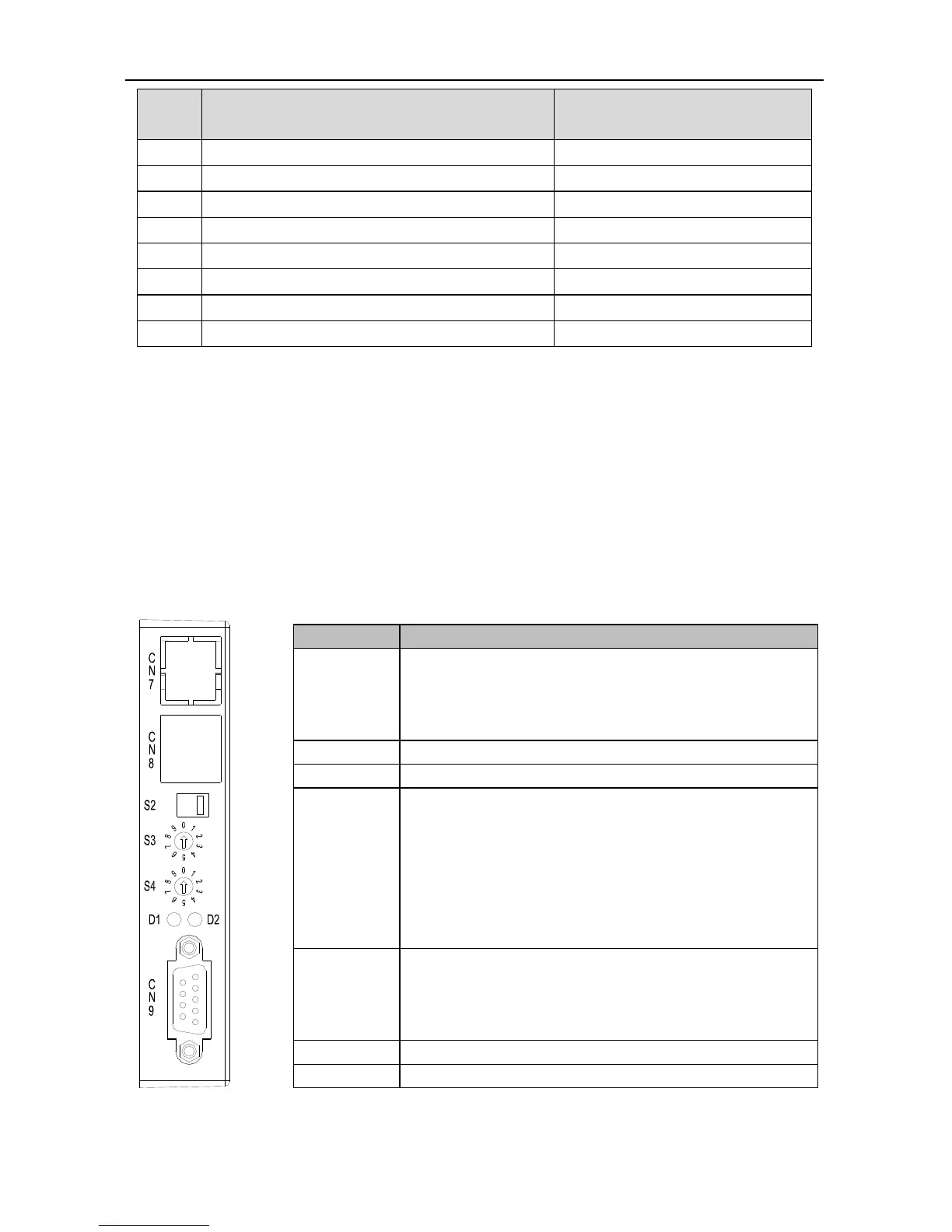

Display Fault name

32-bit fault code(16-bit Error

Code+16-bit additional message)

during operating

Er26-9 CANopen fault–PDO mapping is not allowed FF01-1A09h

Er26-a CANopen fault–Sync signal is too fast FF01-1A0Ah

Er26-b CANopen fault–Receiving fault FF01-1A0Bh

Er26-c CANopen fault–Sending fault FF01-1A0Ch

Er26-d CANopen fault–Sync signal repeat FF01-1A0Dh

Er26-e CANopen fault–Bus load rate is too high FF01-1A0Eh

Er26-f CANopen fault–Parameter modification state error FF01-1A0Fh

8.4 PROFIBUS-DP communication protocol

8.4.1 Brief introduction to PROFIBUS-DP protocol

PROFIBUS is a fieldbus standard used in automation technology and promoted in 1987 by

Germany's Siemens and other 14 companies and five research institutions. PROFIBUS is short for

PROcess FIeld BUS.

PROFIBUS DP is used in factory automation application, it can control many sensors and actuators

by a central controller and master the state of each module by the standard or diagnostic function.

8.4.2 PROFIBUS-DP hardware configuration

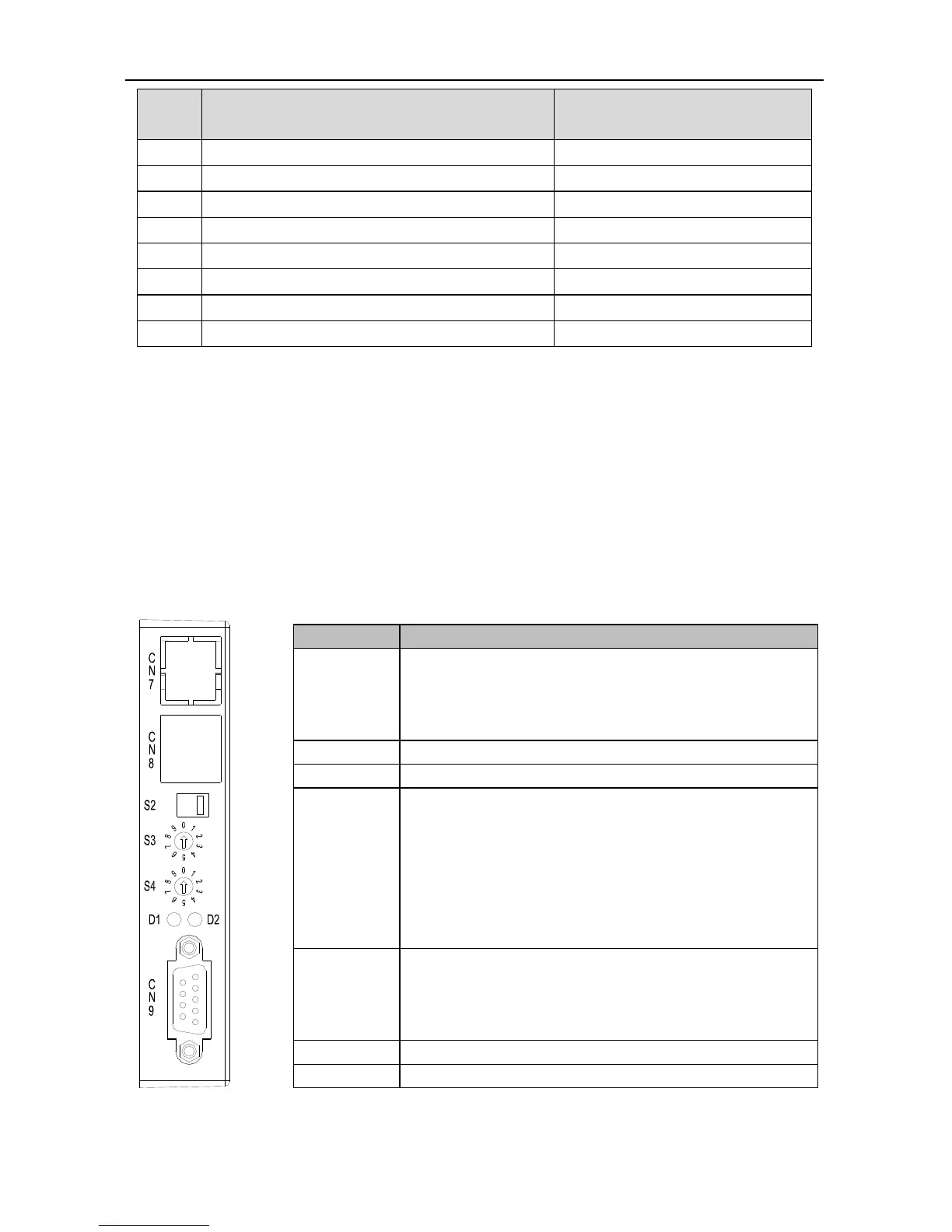

The front side of PROFIBUS-DP communication card is as the figure below:

Name Meaning

S2

PROFIBUS-DP communication terminal resistance

selection switch:

Press down: terminal resistance valid

Hold on: terminal resistance invalid

S3 PROFIBUS-DP station address setting button: ten

S4 PROFIBUS-DP station address setting button: one

D1

PROFIBUS-DP diagnostic lights (red):

Keep on: PRODIBUS-DP communication offline:

Flicker (frequency 1Hz): configuration failure

Flicker (frequency 2Hz): parameters configuration failure

Flicker (frequency 4Hz): ASIC initialization failure;

Off: PRODIBUS-DP communication online and

trouble-free.

D2

PROFIBUS-DP communication On-Line status indicators

(green):

On: online

Off: offline

CN7, CN8 Reserved

CN9 PROFIBUS-DP communication interface

Loading...

Loading...