Figure 24

Figure 25

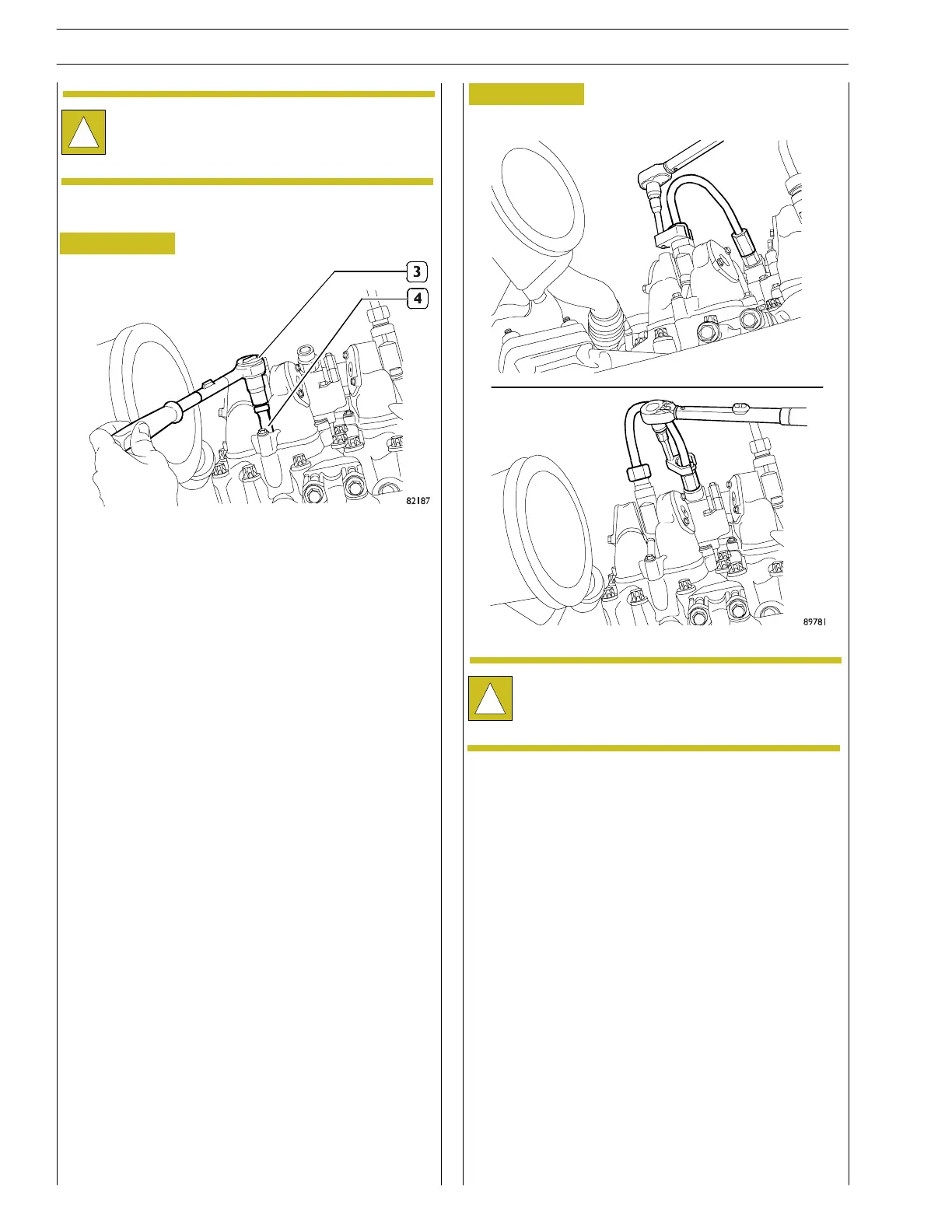

- Tight with a pre- torque of 20 Nm the fitting on both side,

flow-limiter and injector side. Durin g the tightenin g

procedure the injec t or and the flow-limiter have to be

hold against th e tighten direction.

- Tight with a final torque of 80±5 Nm the fitting on both

side, flow-limiter and injector side. During the t ightening

procedure the injec t or and the flow-limiter have to be

hold against th e tighten direction.

- Test engine for leak detection.

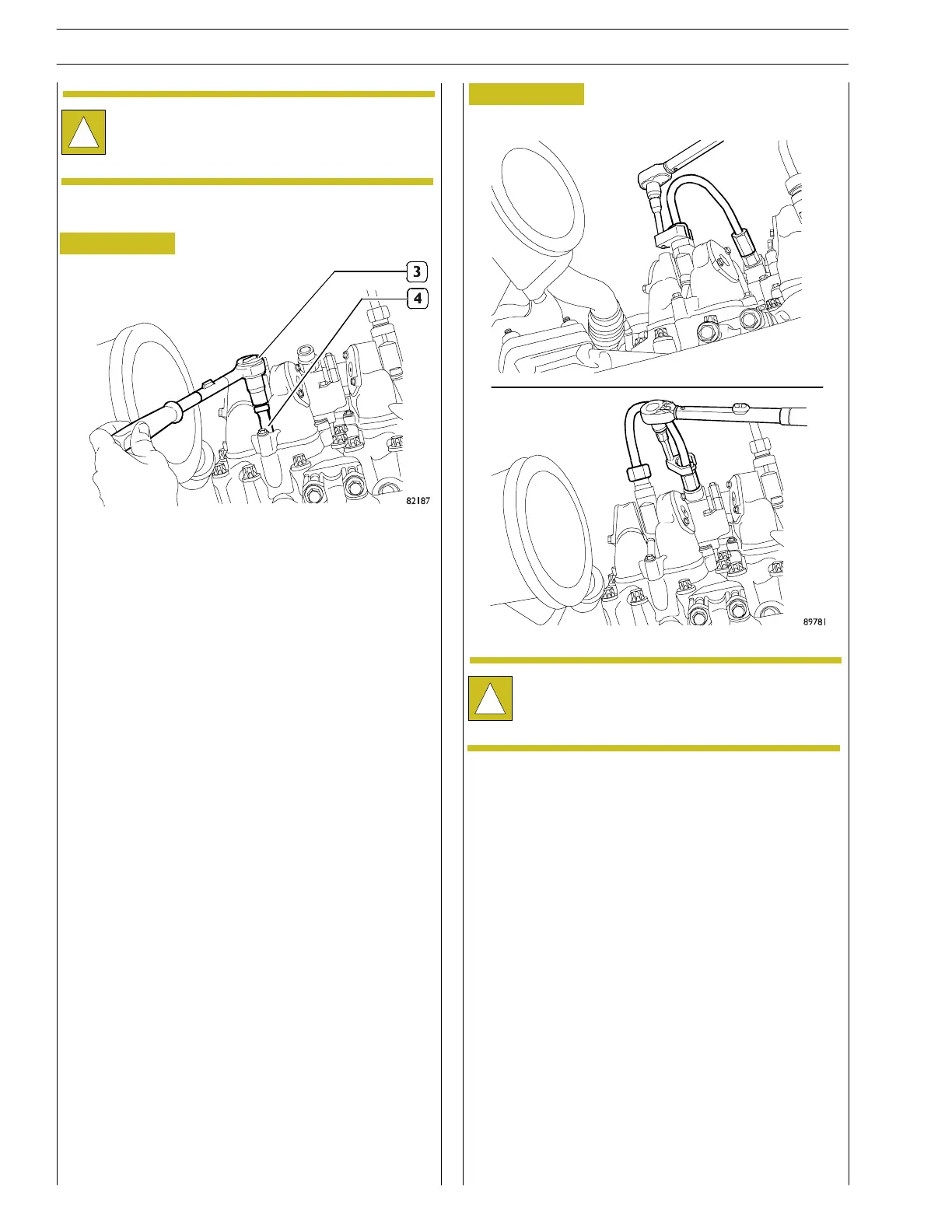

- Using the specific wrench, screw the cheese—headed

screw M10x70 back on to a tightenin g torque of 32 ÷ 36

Nm.

!

Always chan ge the O—ring in t he assembly phase.

Lubricate the O—ring before installation (u se

vaseline).

- Check the sealing surface of the leaking pipe and the

surface on the injector and flow limiter. Cleaning t he

surfaces and remove dirt i f necessary. In case the sealing

surface are damaged , replace the part.

- Lubricate with clean en gine oil the fitting and the sealing

surface.

- Tight by han d t he fitting on both side , flow-limiter an d

injector side.

!

During position ing please clean well the spherical

surfaces and the Threaded part of pipe by dipping it

in a clean contain er filled with clean motor oil.

94

SECTION 3 - INDUSTRIAL APPLICATION

VECTOR 8 ENGINES

Base - April 2006 Print P2D32V001E

Loading...

Loading...