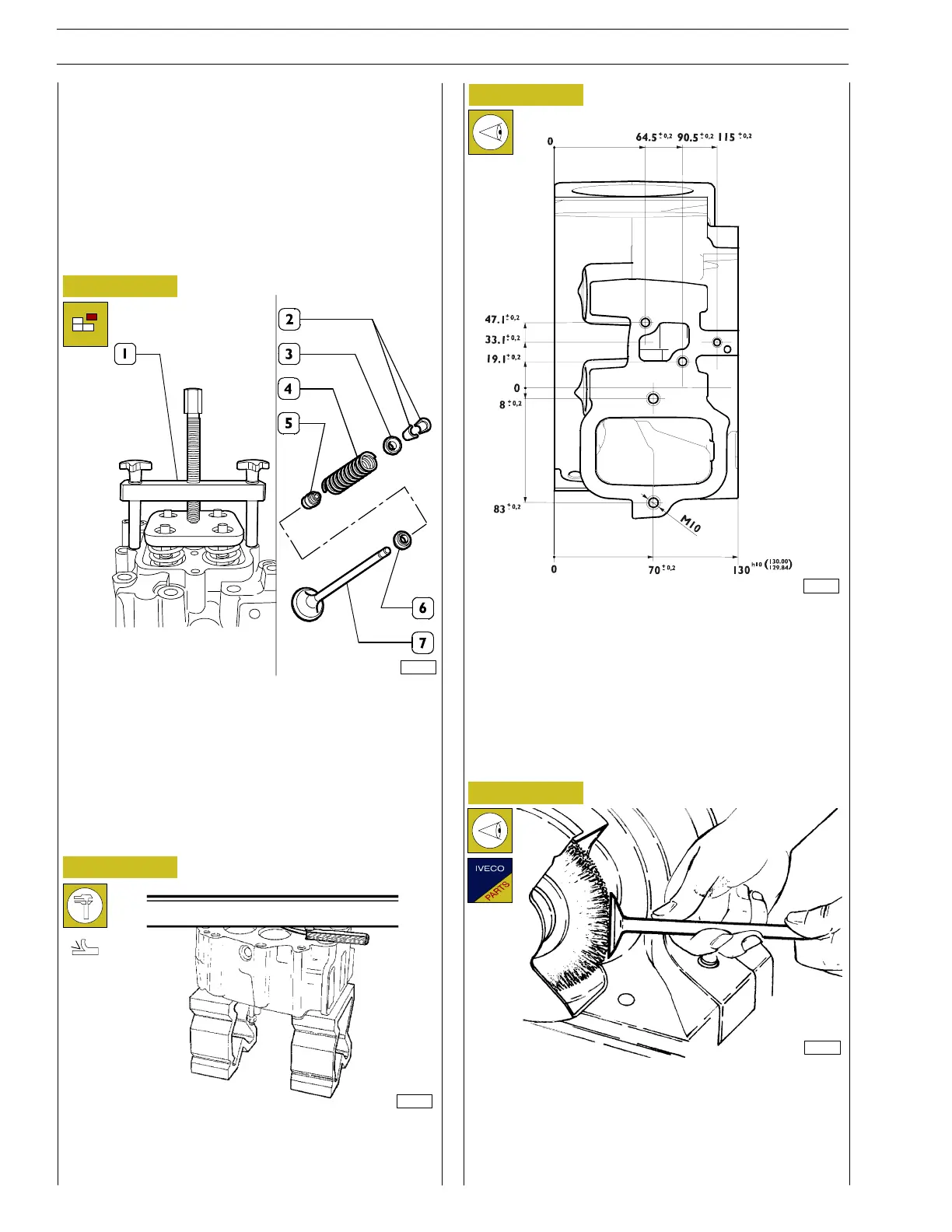

- Rest the cylinder head on the workbench and use tool

99368544 (1) to apply pressure to spring cups (3) so that

by compressing springs (4) valve collets (2) can be

removed.

Then take off upper cups (3), springs (4), caps (5) and

lower cups (6).

Turn the cylinder head upside down and withdraw valves

(7). Repeat the operation on all the cilinder heads.

Figure 75

CYLINDER HEAD

Hydraulic leak test

Before dismantling the cylinder head, carry out the hydraulic

leak test using the appropriate tool.

Pump water heated to approx. 90˚ C and at a pressure of

4 ÷ 5 bar into the cylinder head. Under these conditions, no

leaks should be found; if they are, replace the cylinder head.

Dismantling valves

Figure 76

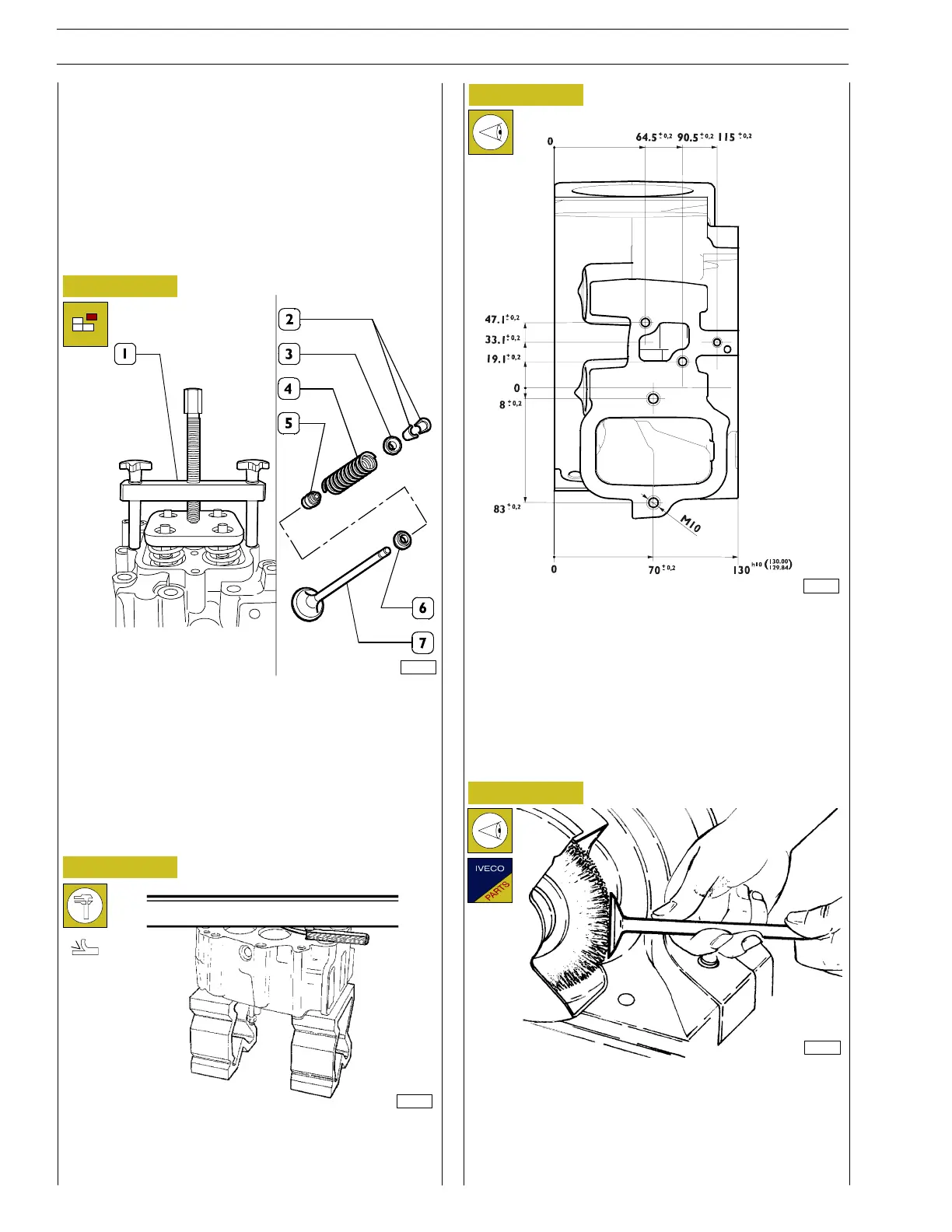

Figure 77

Check the flatness of the support surface using a rule and a

feeler gauge.

- Remove carbon deposits from valve using a steel brush.

Check that valves do not show signs of binding or

cracking.

Use a micrometer to check that the valve rod diamter is

as specified (see Figure 79). If not, replace the valves.

Figure 78

Checking the cylinder head support surface

VALVE

Removing carbon deposits, and checking the

valves

82266

103214

16824

18625

34

SECTION 4 - OVERHAUL AND TECHNICAL SPECIFICATIONS

VECTOR 8 ENGINES

Base - April 2006 Print P2D32V001E

Loading...

Loading...