Figure 82

COMMON RAIL ASSEMBLY PROCEDURE

Preparing for assembly

- This procedure allows to have the best assembling,

reducing the stress on the CR components due to

tolerances and misalignments and will avoid the risk to

have dangerous fuel leakage under pressure, during all

typical condition of the Vector engines operative duty.

- This procedure will apply during first CR assembling in

manufacturing plant as well as during maint enanc e and

replacement of one or more CR components

Cleaning and preparation

- Before mounting, assure that each pipe is protected with

appropriate plastic c ap supplied by Bosch. Remove by

hands the protective caps just before the installation. Do

not use sharp tooling that might cause damage on the

sealing surface. All pipes have to be cleaned up and to

be particul ate free, and t he sealing s urface have to be

without any defect.

- All sealing surfaces, nuts and threads have to be

lubricated with clean engine oil (for example: 15W40).

Assembly procedure

- The high pressure pump (HPP) and the injector’s are

mounted firmly in average position of bolt clearan ce,

with the defined tightening torque.

- All the pipes are fitted by only tightening the areas

connected to the HPP, the rails and t h e injectors

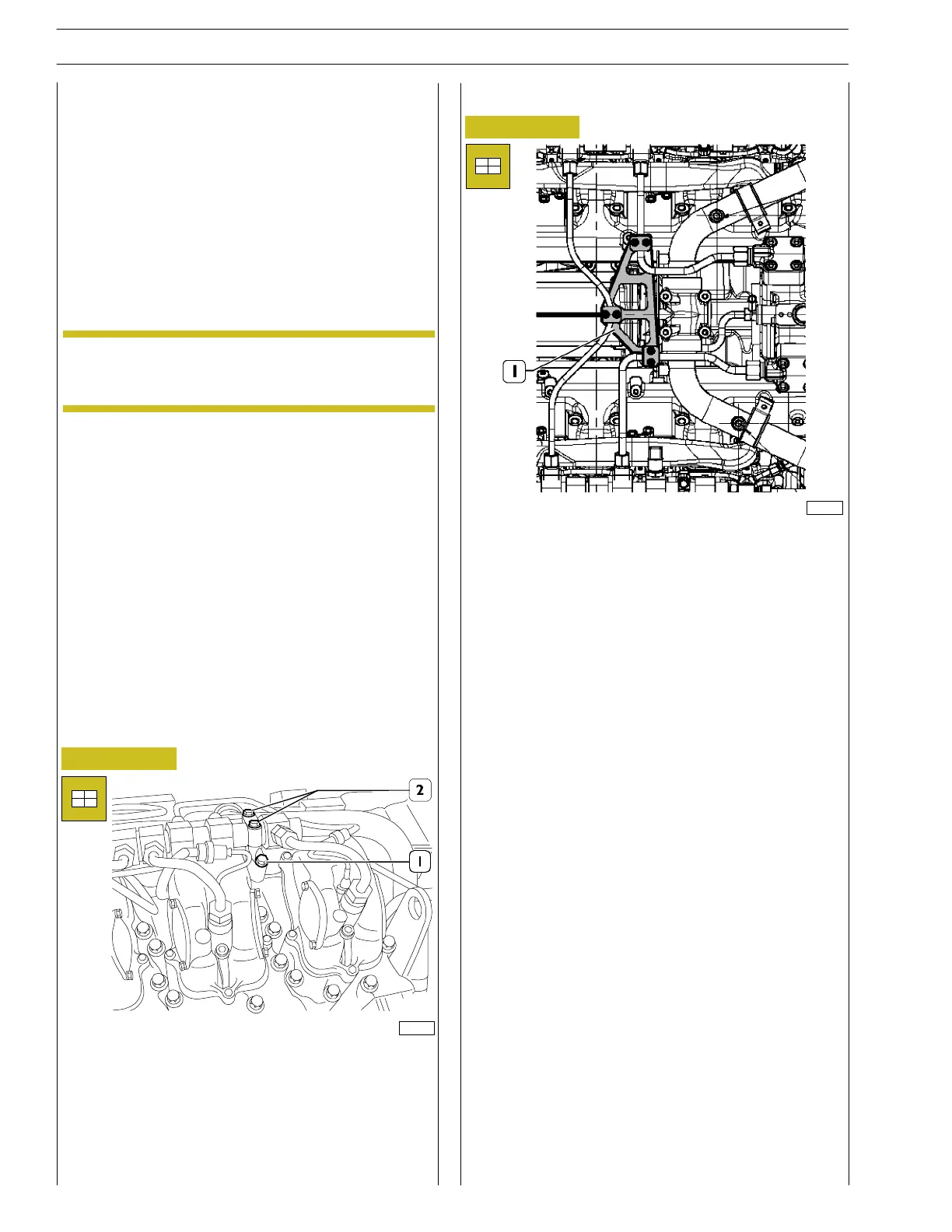

manually (J1.1 - J8.2, V1.1 - V3.2: see Figure Figure 84).

Fit the centre support plate (1) closing the fastenings for

the pipes from the HPP to the rails, from the rails to the

injectors and on the intermediate pipe checking that the

centre pipes are kept in a horizontal position and are flat.

Apply a pre- tightening torque of 20 Nm and then a

pre-tightening torque of 50 Nm to all the connectors.

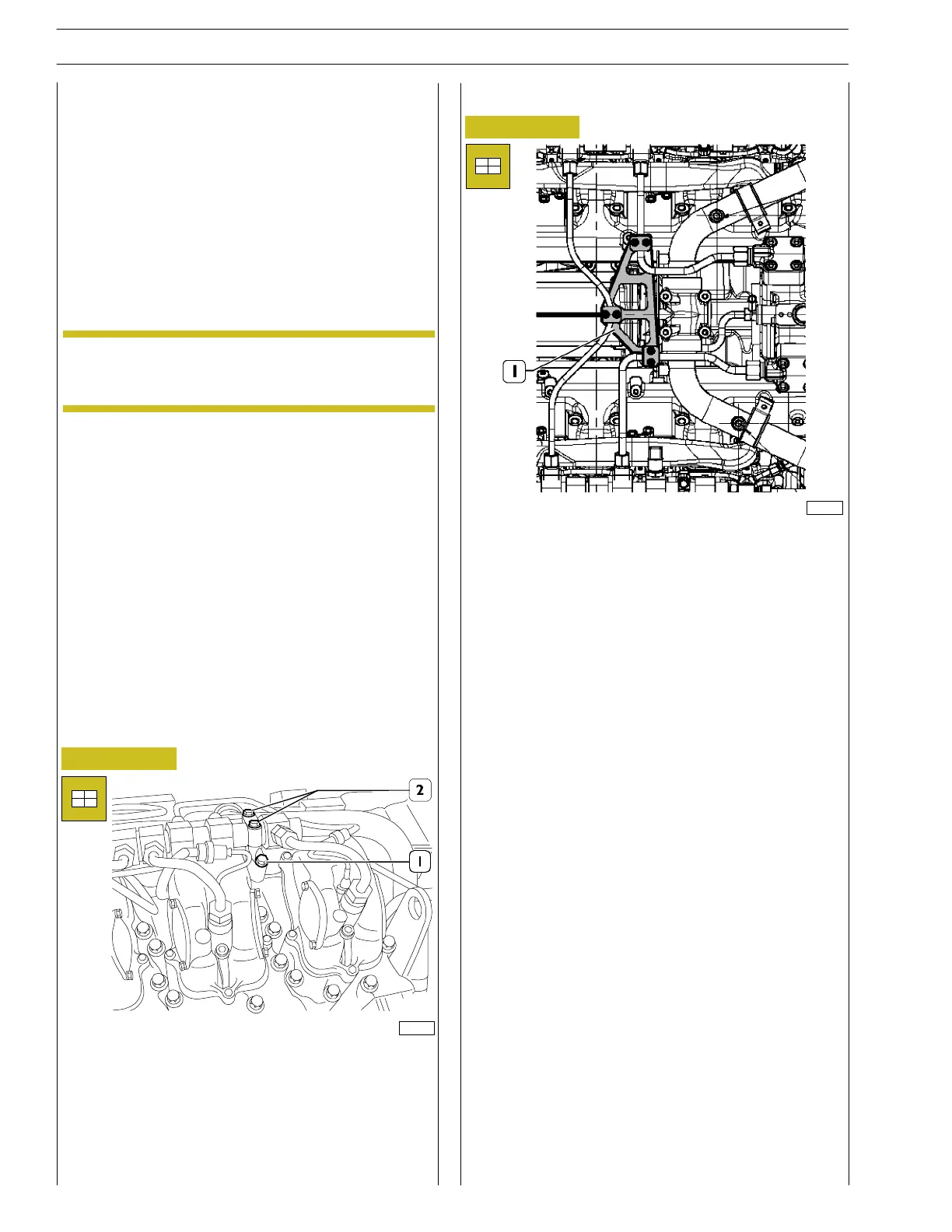

Figure 83

112491

It is vital to use a special torque wrench for the

fitting procedure described here.

NOTE

- The rails are installed on th eir supports, previously fixed

on the cylinder heads by the related screws tightened

with proper tightening torque of 25 Nm (screws 1). The

rails have to be in horizontal position and aligned and the

fixing caps have to be positioned with the related screws

loose o n the support (screws 2).

82259

- lubricate all the connectors with clean oil.

38

SECTION 3 - INDUSTRIAL APPLICATION

VECTOR 8 ENGINES

Base - April 2006 Print P2D32V001E

Loading...

Loading...