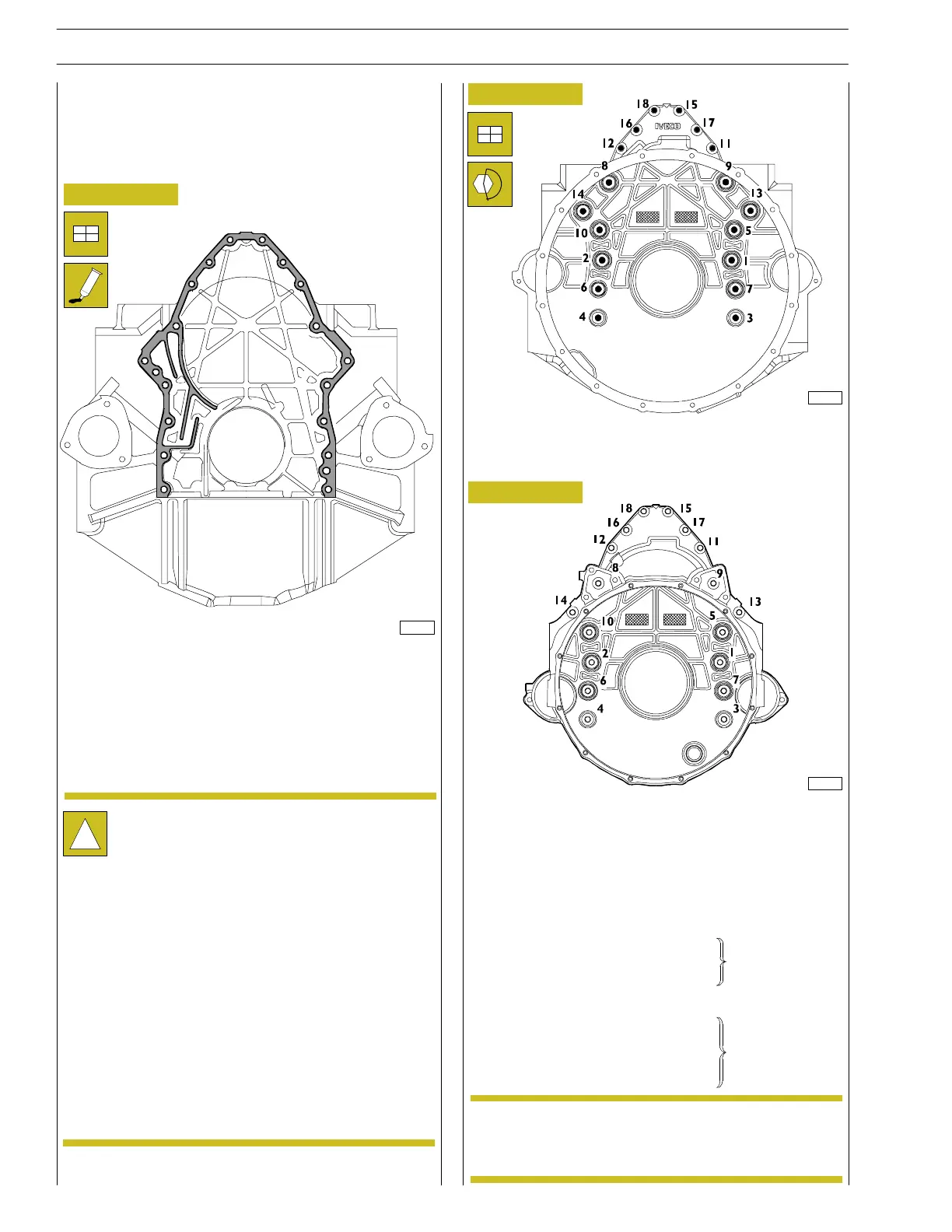

- Form a bead of IVECO 2992692 sealant as s hown in the

figure.

Figure 39

Installation of components for the application

Fitting the flywheel cover housing

- Carefully clean the contact sides between the crankcase

and the flywheel cover housing, removing any remains

of sealant with a scraper.

!

A perfect seal is only obtained by carefully cleaning

the surface to seal.

Smear the case with IVECO SEAL 2992692 to

obtain a bead of a few mm diameter.

It sh all be uniform (no clots), wit hout air bubbles, thin

areas or discontinuities.

Any imperfection shall be corrected as soon as

possible.

Avoid using excess material to seal the joint.

Excessive sealant could come out from joint sides

and cause lubricant passage clogging.

After applying the sealant, the joint shall be

assembled immediately (10—20 minutes).

103197

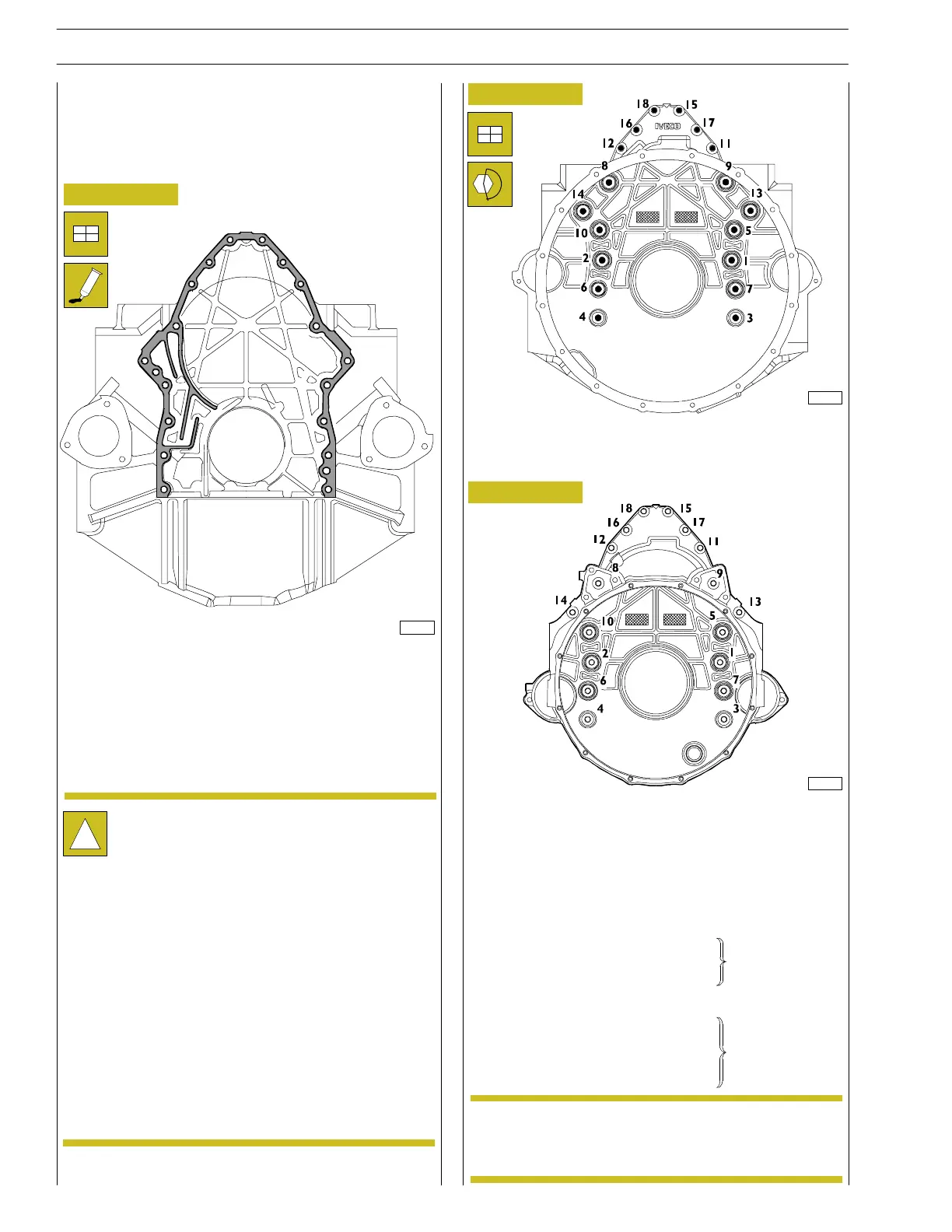

Figure 40

DIAGRAM SHOWING TIGHTENING ORDER FOR

BOLTS FIXING FLYWHEEL COVER CASING O N

G- DRIVE APPLICATION

103198

NOTE

Make sure you put th e screws in t he seats from

where they were taken. There are screws of

different lengths as well as different sizes.

Figure 41

DIAGRAM SHOWING TIGHTENING ORDER FOR

BOLTS FIXING FLYWHEEL CASING COVER FOR

GRIFFON, DRAGON and SPRINKLER APPLICATIONS

- Refit the housing (1) to the engine block and screw the

fastening screws in the same position found at removal

and tighten them to the following torque values in the

sequence shown in the figu re:

M12x1.75x45 torque 89 to 105 Nm

M14x2x90 torque 135 to 165 Nm

M12x1.75x45 torque 89 to 105 Nm

M14x2x90 torque 135 to 165 Nm

M14x2x110 torque 135 to 165 Nm

83507

G-DRIVE

Application

GRIFFON,

DRAGON and

SPRINKLER

Applications

22

SECTION 3 - INDUSTRIAL APPLICATION

VECTOR 8 ENGINES

Base - April 2006 Print P2D32V001E

Loading...

Loading...