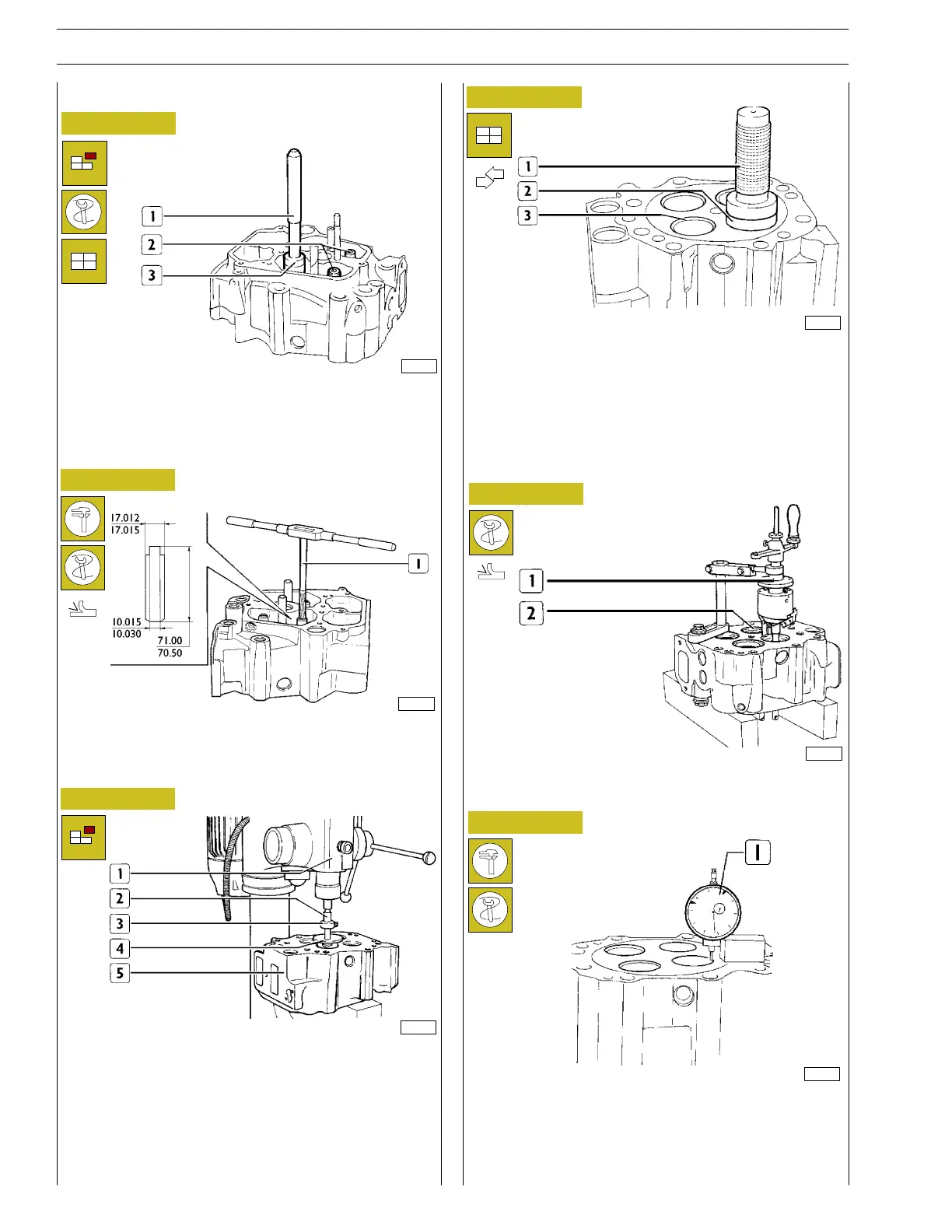

Figure 83

Figure 84

Figure 85

- Using the reamer (1), ream the valve guide bore to obtain

the indicated value.

Replacing and regrinding the valve seats

- Dismantle the valve guides (2) with beater 99360143 (1);

mount the new valve guides using a beater 99360143 (1)

fitted with part 99360291 (3).

Replacing the valve guides

Reaming the valve guides

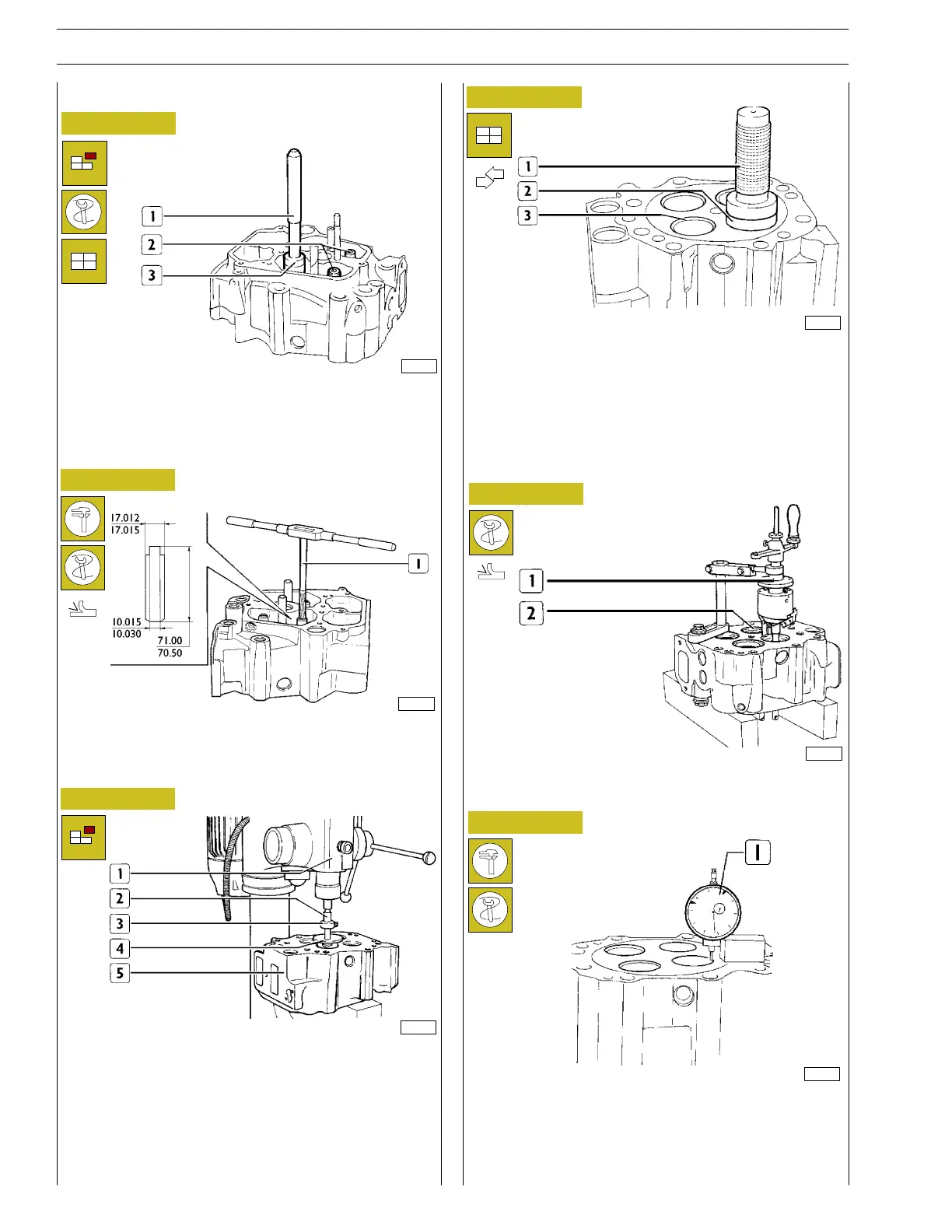

Figure 86

Figure 87

Figure 88

Replace the valve seats as follows:

- place the cylinder head (5) on the pillar drill (1);

- fit tool (4) on the pillar drill;

- adjust the stop device (3) on the milling cutter (2);

- operate the milling cutter and remove the valve seat;

- thoroughly clean the cylinder head.

- cool the new valve seats to — 180°C in liquid nitrogen;

- drive the valve seats (3) into the cylinder head with a drift

(1) and suitable part (2).

Assembly interference:

- inlet: 0.015 to 0.035 mm

- exhaust: 0.015 to 0.035 mm

- Regrind the valve seats (2) with tool 99305019 (1).

After regrinding the valve seats, use a dial gauge (1) on tool

99370415 to check that:

- the valve recessing is from 0.50 to 0.80 mm.

16830

16833

16834

82263

16835

16832

36

SECTION 4 - OVERHAUL AND TECHNICAL SPECIFICATIONS

VECTOR 8 ENGINES

Base - April 2006 Print P2D32V001E

Loading...

Loading...