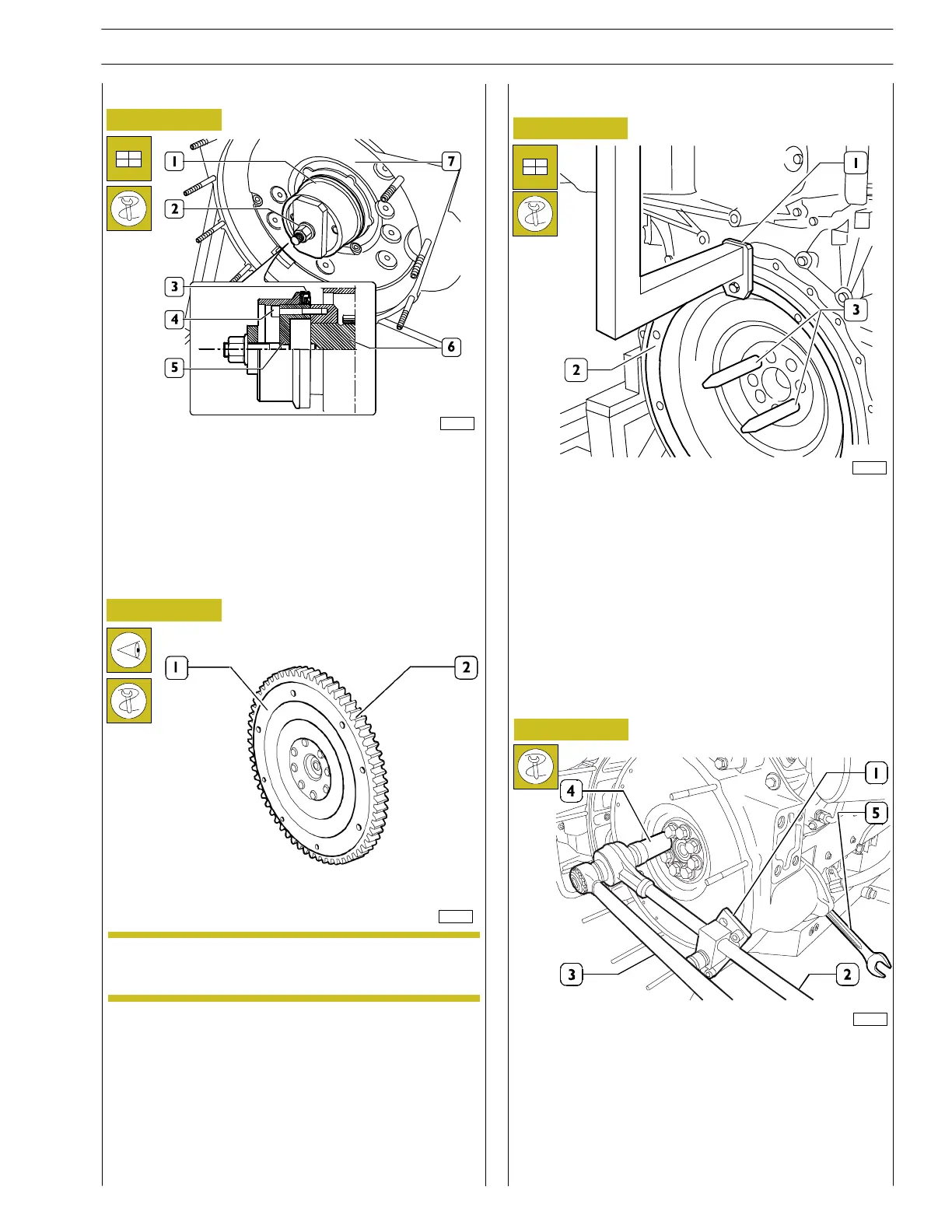

Figure 42

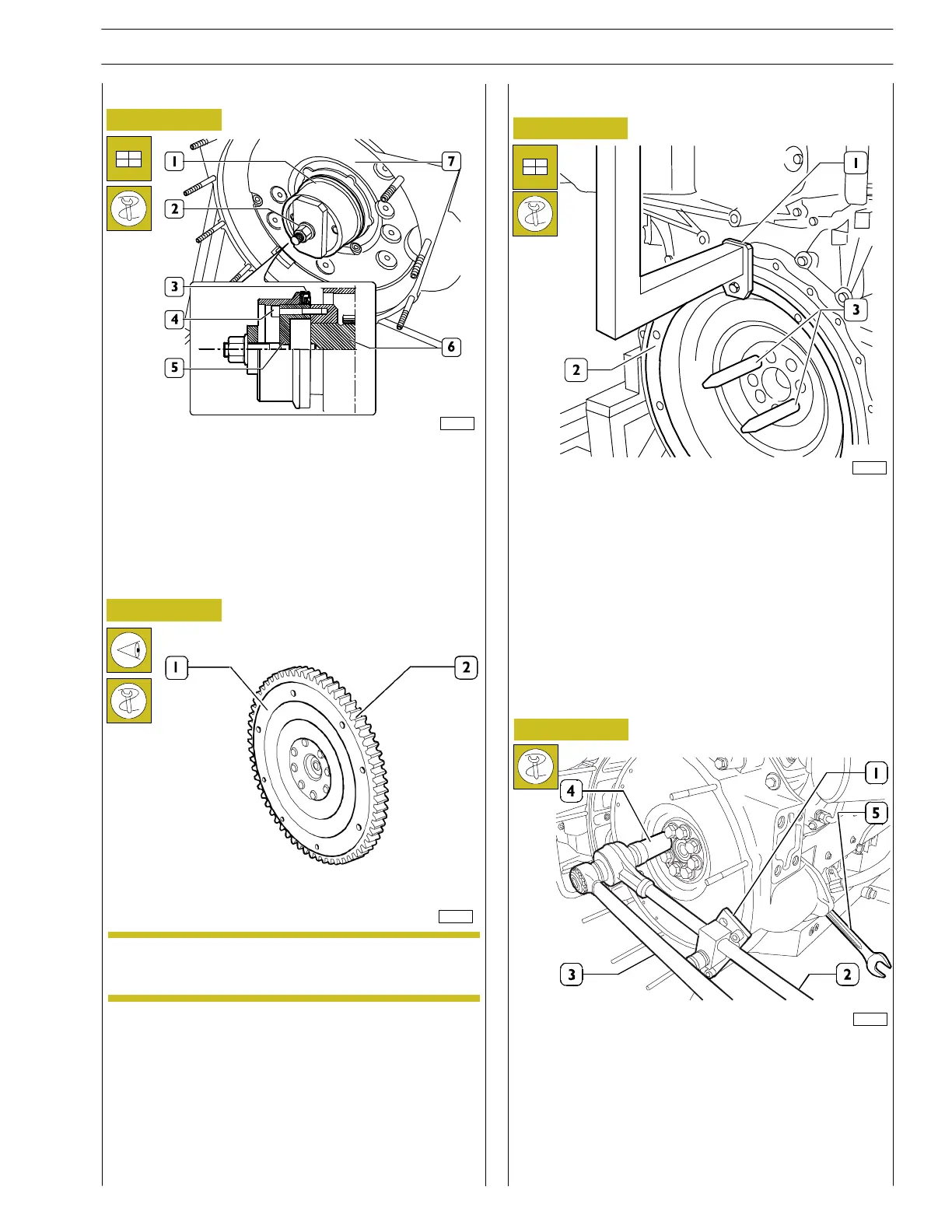

Figure 43

- Apply tool 99368511 part (6) to the rear output shaft

tang (5), secure it with screws (4) and fit the new sealin g

ring (3).

Position part (1) on part (5), screw nut (2) until

completing sealing ring (3) fitting into flyw heel housin g

(7).

ENGINE FLYWHEEL

00901t

75696

NOTE

Check the important measurements depending on

the application.

- Check the condition of the teeth for the ring gear (2).

If the teeth are broken or very worn, remove it from the

engine flywheel (1) using an ordinary drift and fit the new

ring gear, heated previously to a temperature of 150˚C

for 15’ P 20’; the bevel on the inner diameter of the ring

gear should be facing the engine flywheel.

Figure 44

- Screw the pins 99367019 (3) onto t he crankshaft and fit

the flywheel (2) with tool 99368533 (1) and a suita ble

lift.

Fitting the engine flywheel

83436

Figure 45

- Stop engine shaft rotation with tool 99368502: the fixed

wrench (5) keeps the flywheel in position preventing its

rotatio n. Assemble tool 99368546 (1) and tigh ten the

fixing sc rews that were previously lubricated with

”UTDM” oil up to the prescribed torque by using torque

multiplier 99389816 (2), dynamometric wrenc h

99389818 (3) and bush wrench 99367016 (4); for

angular closu re use tool 99395216 (2).

103216

Fitting the rear oil seal

SECTION 3 - INDUSTRIAL APPLICATION

23

VECTOR 8 ENGINES

Print P2D32V001E Base - April 2006

Loading...

Loading...