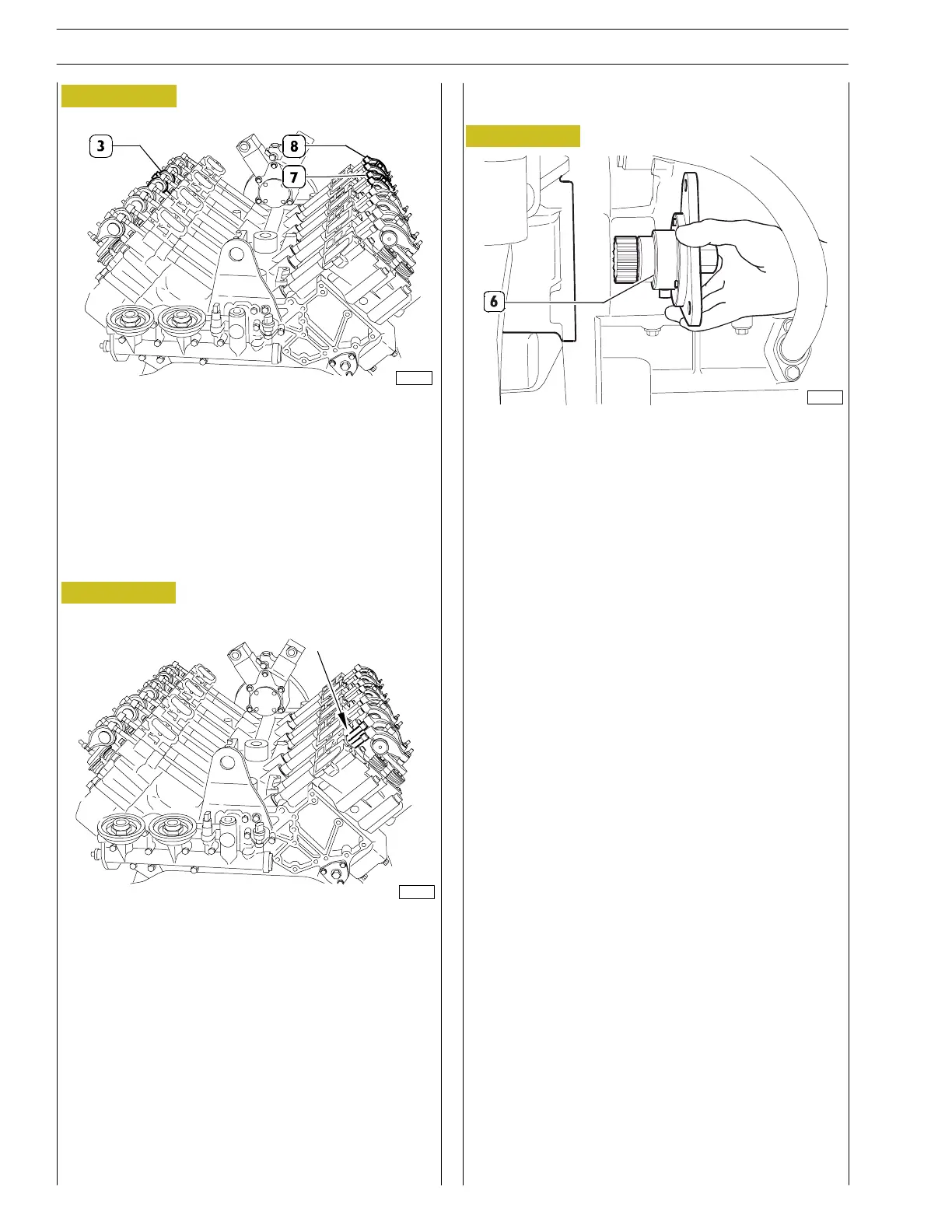

Figure 57

Adjusting operating clearance between valves

and rockers

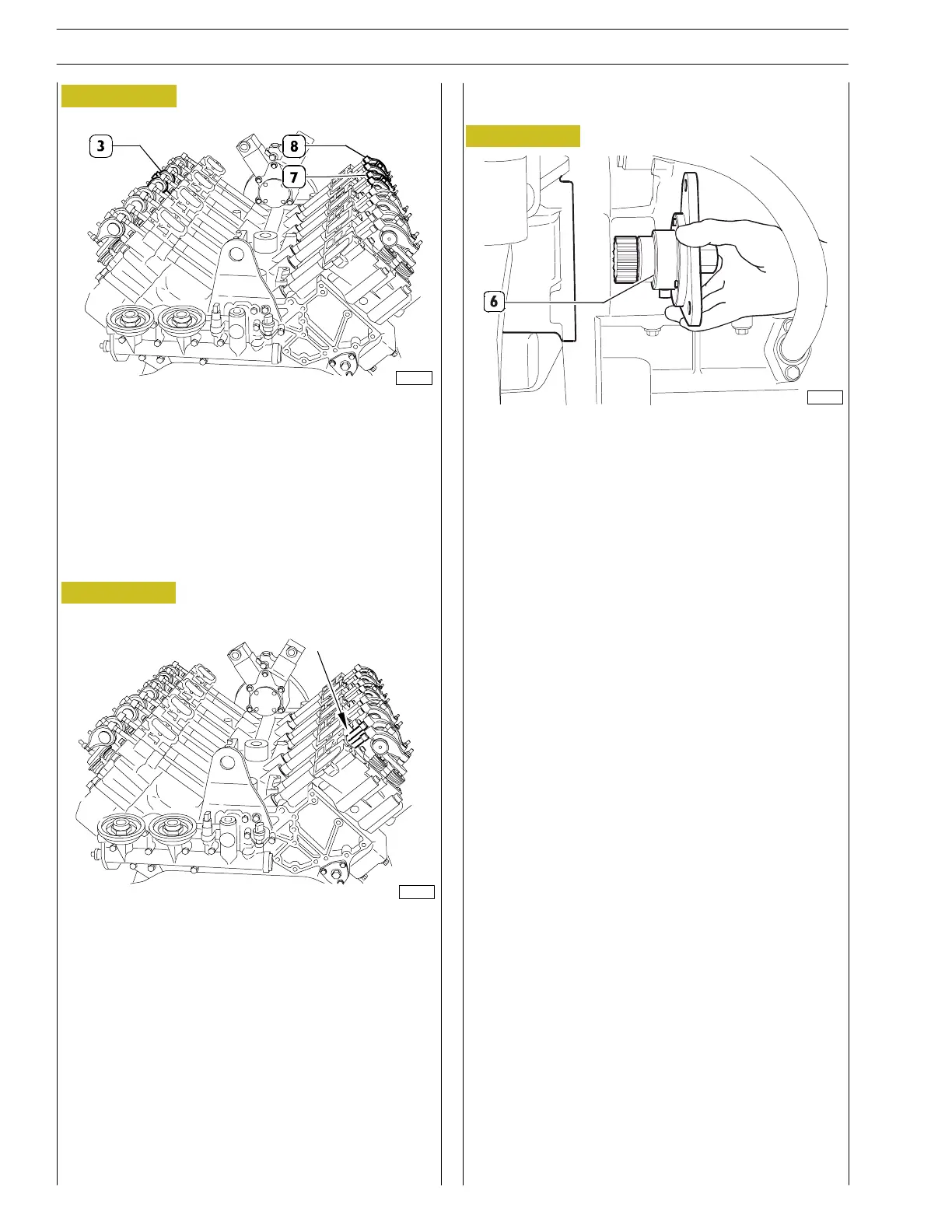

- Undo the three nuts fixing the flywheel cover casing

cover (side opposite the starter motor). Fit tool

99368502 (6) with pinion 99368547 to rotate the engine

flywheel and secure it using the nuts for the cover

removed.

- After fitting the 24 mm ratchet wrench on the back of

tool 99368502, turn the engine flywheel until we obtain

the required cylinder balanc i ng (the 4 valves are at the

same height).

Figure 58

- Unscrew the three fixing nuts of the cover of the box

that covers the flywheel (on the opposite side of the

starting mot or). Insert tool 99368502 in order to turn

the engine flywh eel an d fix it with the nu t s of th e cover

that has been removed.

- Turntheengineclockwisefor360˚, th en assemble

rocker—arm unit s 3-7 e 8.

- Check that the contact between the register and the

plate is centred and that the rods can turn freely.

Figure 59

- Apply the 20 ÷ 120 Nm torque wrench with the 1/2”

square connect ion to the wrench 99389813 to lock

bolts M12x1,75 to a torque of 80 ÷ 89 Nm.

- After the rocker—arm control rods (1) have been

assembled check that they are properly inserted in the

tappet seats and then lubricate then with engine oil in the

area in which the rod slides.

89827

81603

89829

28

SECTION 3 - INDUSTRIAL APPLICATION

VECTOR 8 ENGINES

Base - April 2006 Print P2D32V001E

Loading...

Loading...