Figure 3

Figure 4

- Once engine is disassembled, clean accurately the

cylinder—block assembly. Use the proper rings to handle

the cylinder unit. The engine block shall not show cracks.

- Check operating plug conditions and replace them in case

of uncertain seal or if rusted.

- Inspect cylinder barrel surfaces; they shall be free from

seizing, scores, ovalisation, taper or excessive wear.

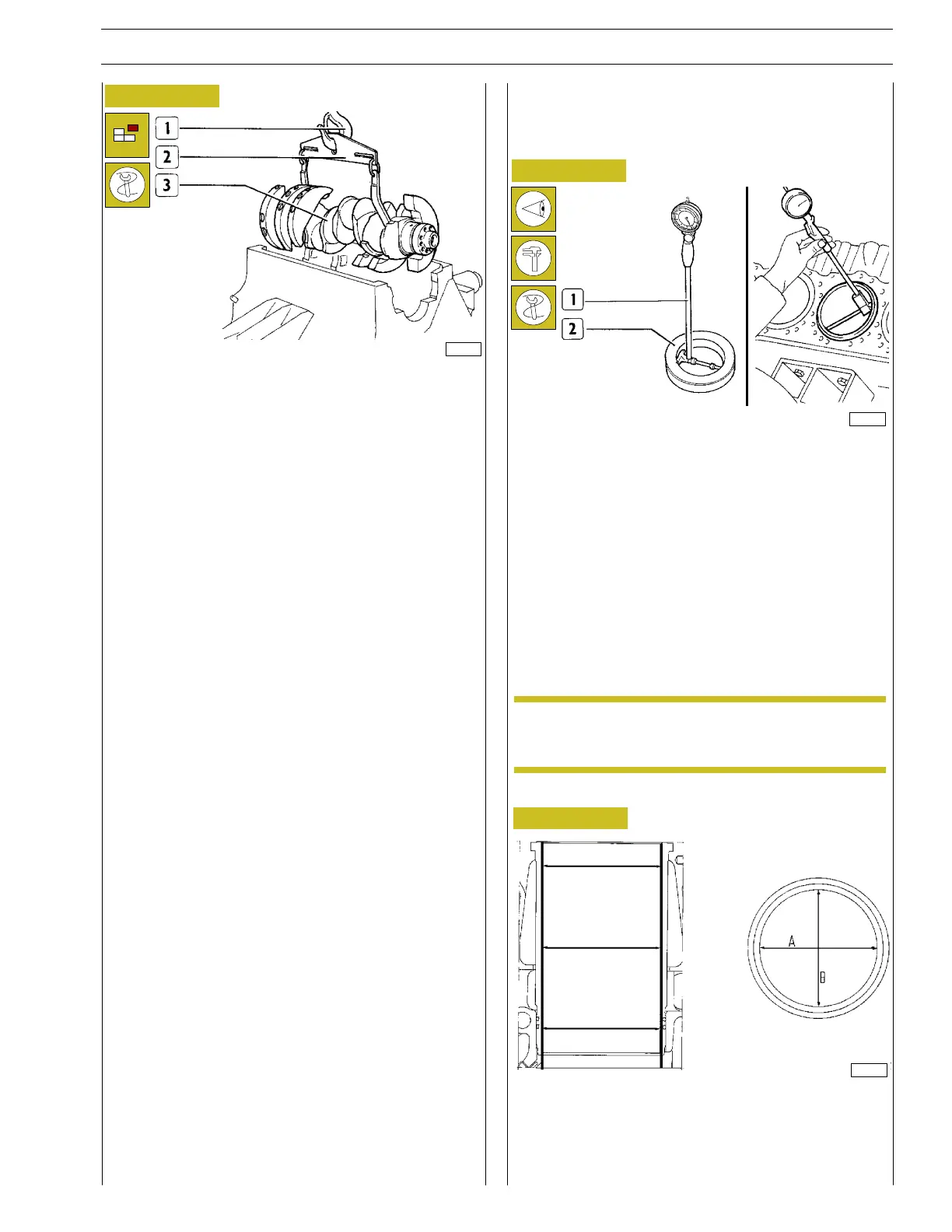

Inspection of cylinder barrel bore to check ovalisation,

taper and wear shall be performed using the bore dial

gauge 99395687 (1) fitted with the dial gauge previously

set to zero on the ring gauge (2) of the cylinder barrel

diameter.

Figure 5

REPAIR OPERATIONS

CYLINDER UNIT

Checks and measurements

Should the ring gauge be not available, use a

micrometer for zero—setting.

- Measurements shall be performed on each cylinder, at

three different heights in the barrel and on two planes

perpendicular with each other: one parallel to the

longitudinal axis of the engine (A), and the other

perpendicular (B). Maximum wear is usually found on plane

(B) in c orrespondence with the first measurement.

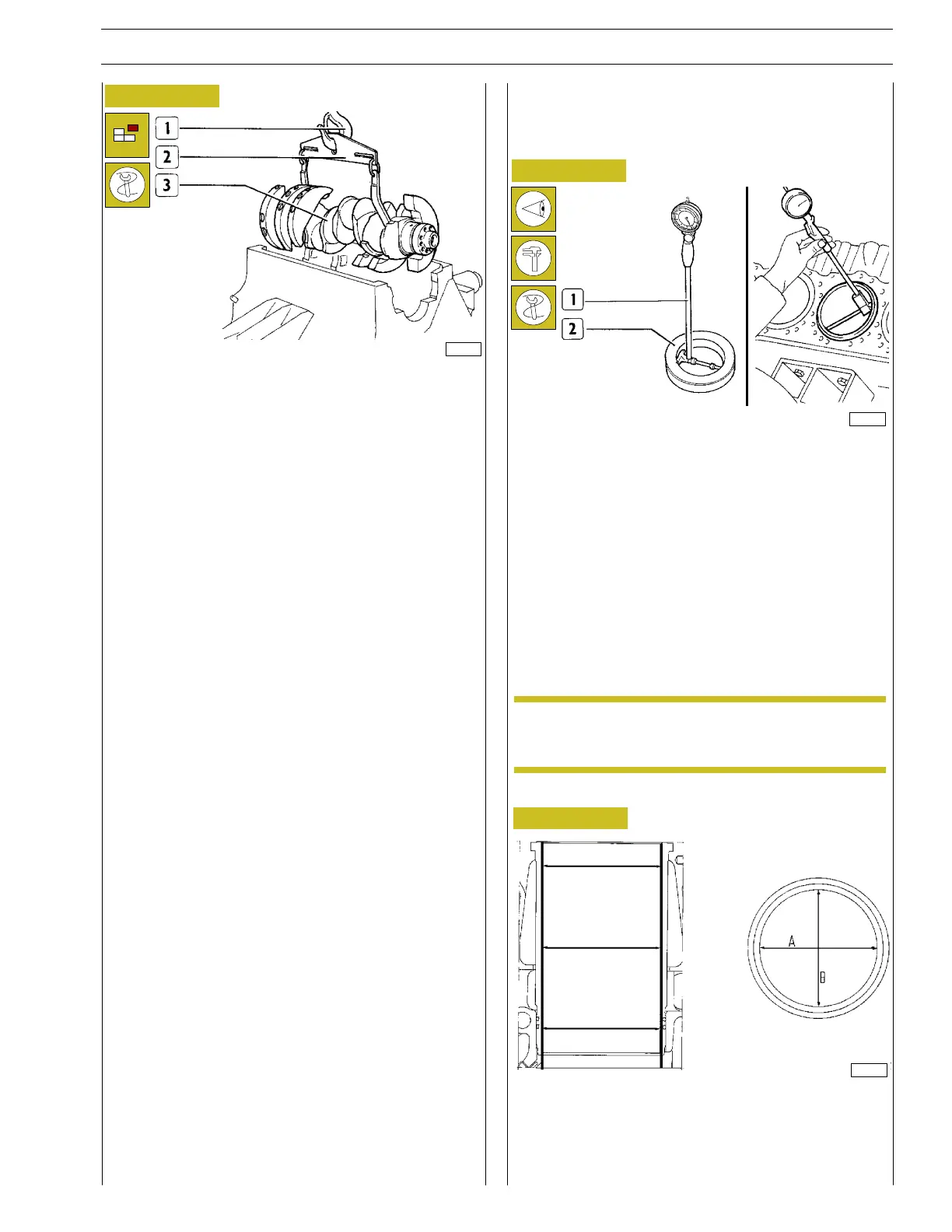

- Using a hoist (1) and tool 99360500 (2), appropriately

fitted on the crankpins, extract the crankshaft (3) from the

cylinder assembly.

- Extract the camshaft from the cylinder assembly, taking

care not to damage the supporting bushings. Extract the

roller tappets.

1

2

3

16788

16792

NOTE

2284

SECTION 4 - OVERHAUL AND TECHNICAL SPECIFICATIONS 11

VECTOR 8 ENGINES

Print P2D32V001E Base - April 2006

Loading...

Loading...