Figure 85 Figure 86

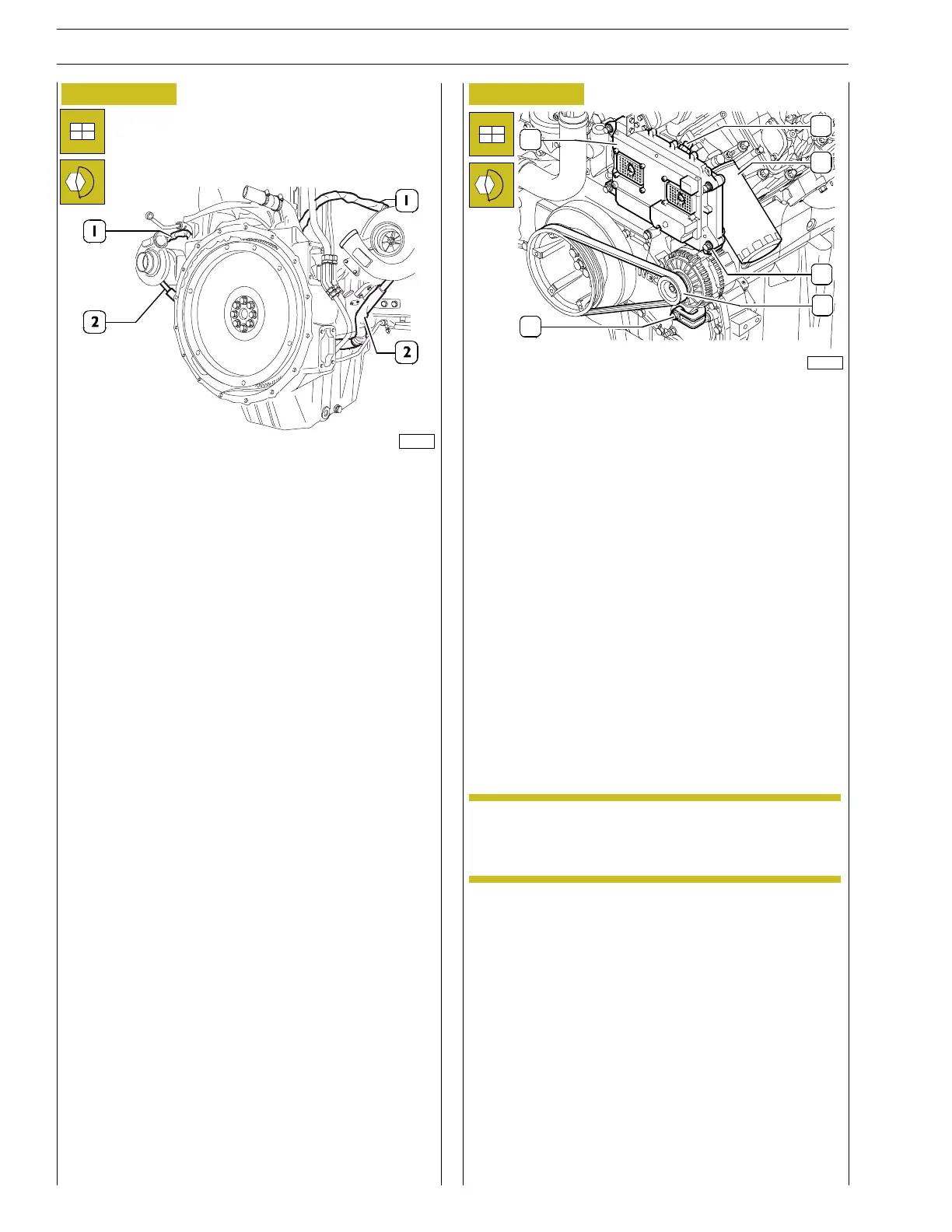

- Fit the oil pipes (1) and (2) for lubricating the turbines.

Tightening torques:

screw fixing bottom pipes draining oil from th e

turbo—blower to the oil sump — M8x1.25 = 22—27 Nm.

Screw fixing pipes delivering o il to the tu rbo—blower —

M8x1.25 = 22—27 Nm.

- Fit the engine support.

Screw fixing rear engine support (M16x2)

1st step Torque: 95÷105 Nm

2nd step Angle: 85˚-90˚

Guard torque: 310÷420 Nm

Screw fixing front engine support (M14x2)

1st step Torque: 65÷75 Nm

2nd step Angle: 60˚-65˚

Guard torque: 190÷270 Nm

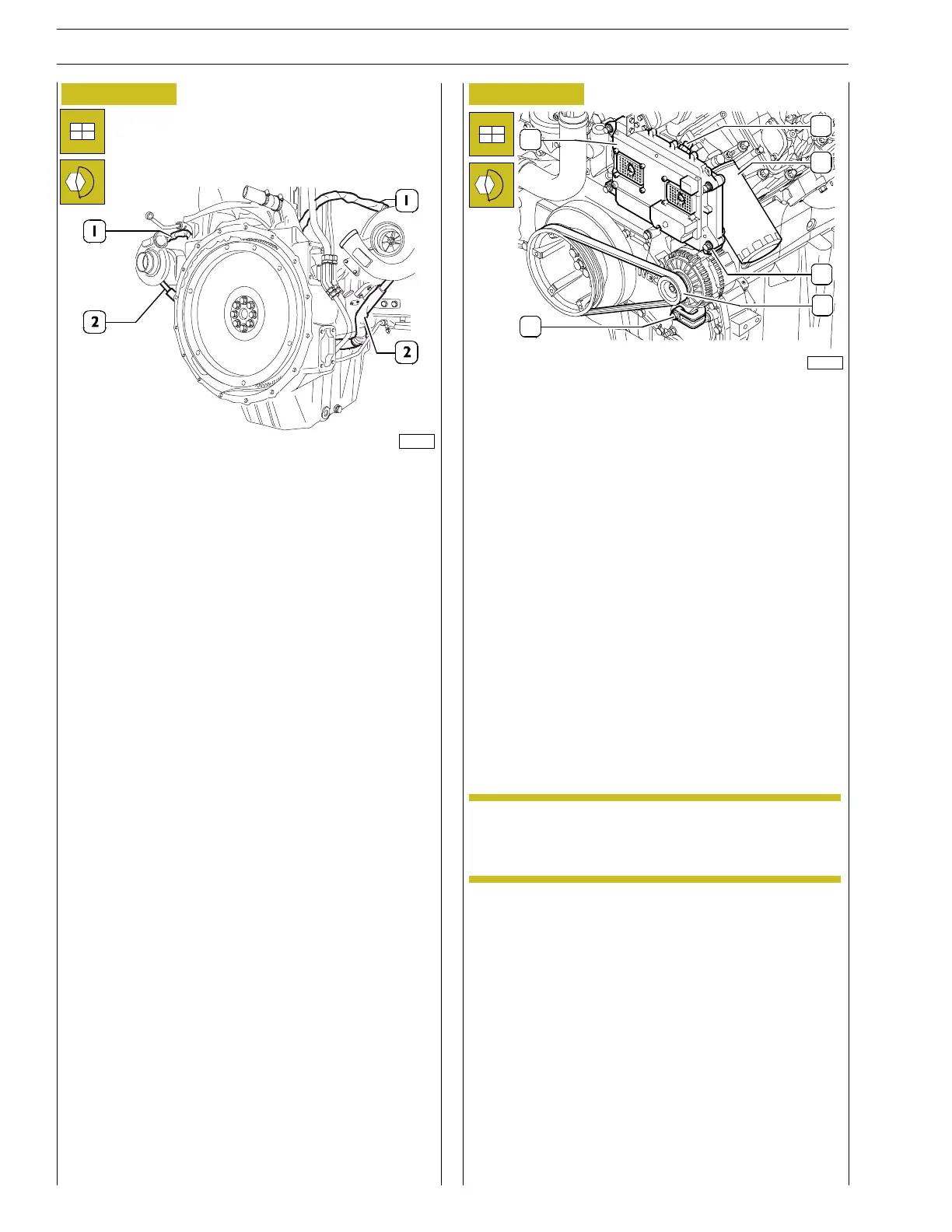

- Fit the control unit support (3) on the engine (M8x1.25

bolts to be tightened to a torque of 22-27Nm) c o mplete

with atmospheric pressure sen sor (5) and diesel filter

mounting.

- If present on the application, fit the air conditioning

compressor (17, Figure 3) and the flexible belt (16, Figure

3).

- Fit the altern ator complete with mounting bracket and

tension t he bolt (6) tightening th e bolt (5).

- Fit the ADEM III control unit (2) on the support with the

flexible mounts (3) (M8x1.25 screws t o tighten to a

torqueof22—27Nm).

- Fit the engine elec tric cable connecting the control unit

to the various sensors and services.

Suitably secu re the electric cable on the engine with th e

clamps.

- Fit th e oil filters and the diesel filter (if present).

- Fit th e protective grilles (if present).

- Affix t he plate warning the engine has no lubricating oil.

103228

103227

5

6

3

4

1

2

NOTE

The filters must be tightened by hand after lightly

lubricating the seals.

Tighten for anoth er 3/4 t urn with 99368539 tool.

40

SECTION 3 - INDUSTRIAL APPLICATION

VECTOR 8 ENGINES

Base - April 2006 Print P2D32V001E

Loading...

Loading...