− 15 −

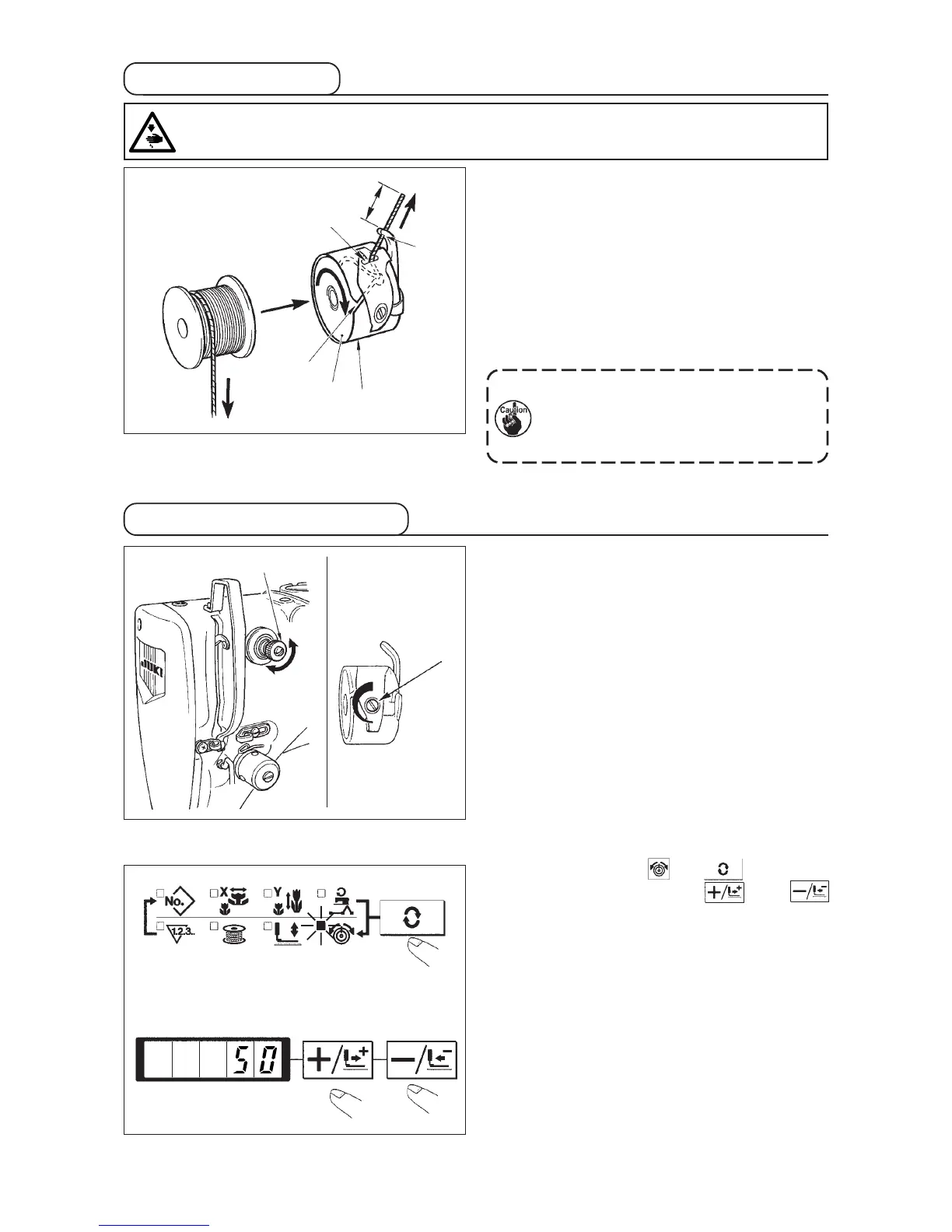

Adjusting the needle thread tension

1) Select thread tension with key.

2) Set needle thread tension with key or

key. There is a setting range of 0 to 200. When the

set value is increased, the tension becomes higher.

*The tension is set so that 1.5 N (spun thread

#50) is obtained at the set value 50 at the time

of standard delivery. (When thread tension No.

1 is released)

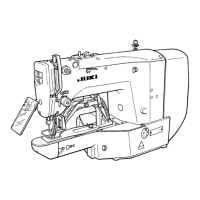

6. Adjusting the thread tension

If thread tension controller No. 1 q is turned clockwise,

the length of remaining thread on the needle after

thread trimming will be shorter. If it is turned

counterclockwise, the length will be longer.

Shorten the length to an extent that the thread is not

slipped off.

Adjust needle thread tension from the operation panel

and bobbin thread tension with w.

q

Short

w

Long

h

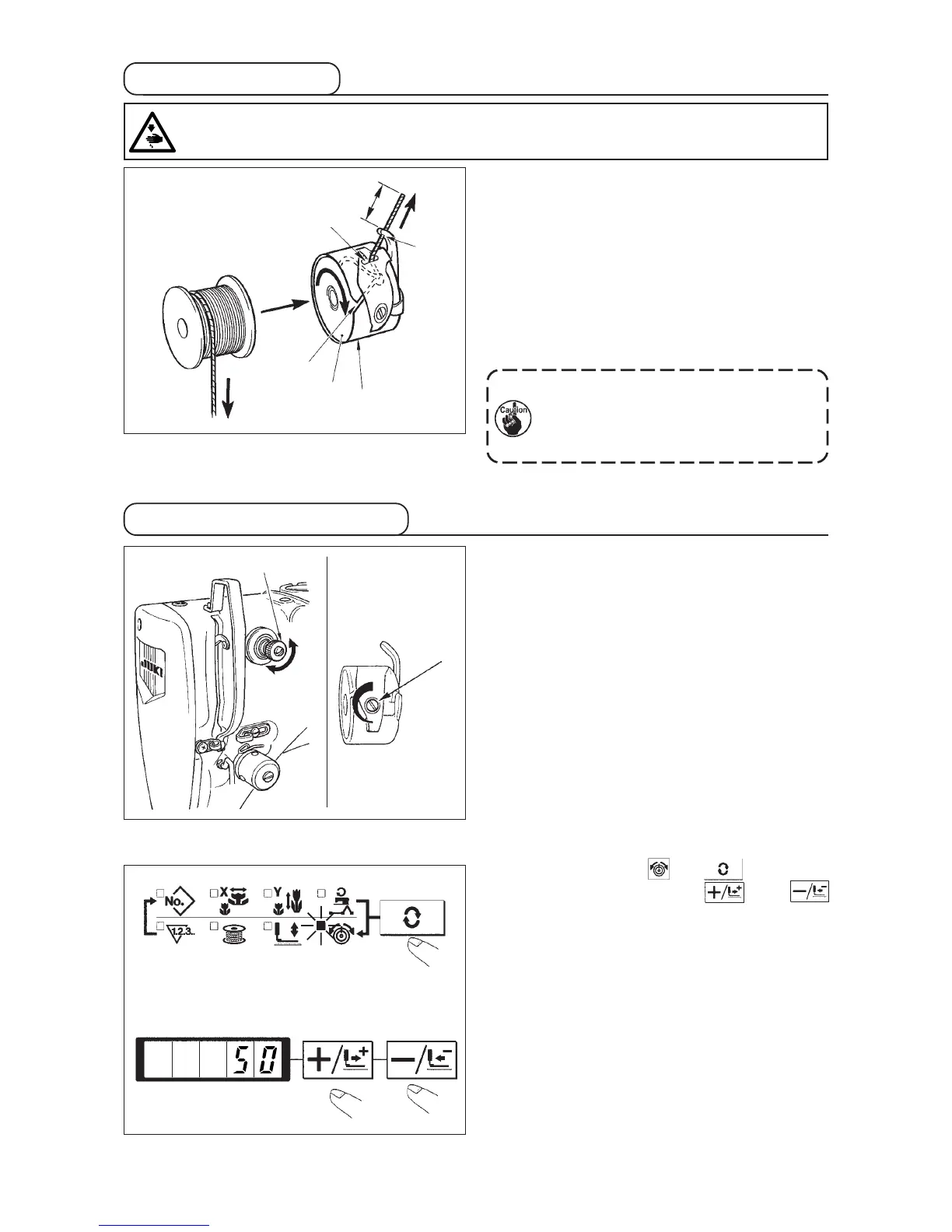

1) Set the bobbin q into bobbin case w in the direction

shown in the figure.

2) Pass the thread through thread slit e of bobbin

case w, and pull the thread as it is. By so doing,

the thread will pass under the tension spring and

be pulled out from thread hole r.

3) Pass the thread through thread hole t of the horn

section, and pull out the thread by 2.5 cm from the

thread hole.

If the bobbin is installed in the bobbin

case orienting the reverse direction, the

bobbin thread pulling out will result in an

inconsistent state.

5. Installing the bobbin

q

w

t

r

e

2.5 cm

WARNING :

Turn OFF the power before starting the work so as to prevent accidents caused by abrupt start of the

sewing machine.

Loading...

Loading...