− 52 −

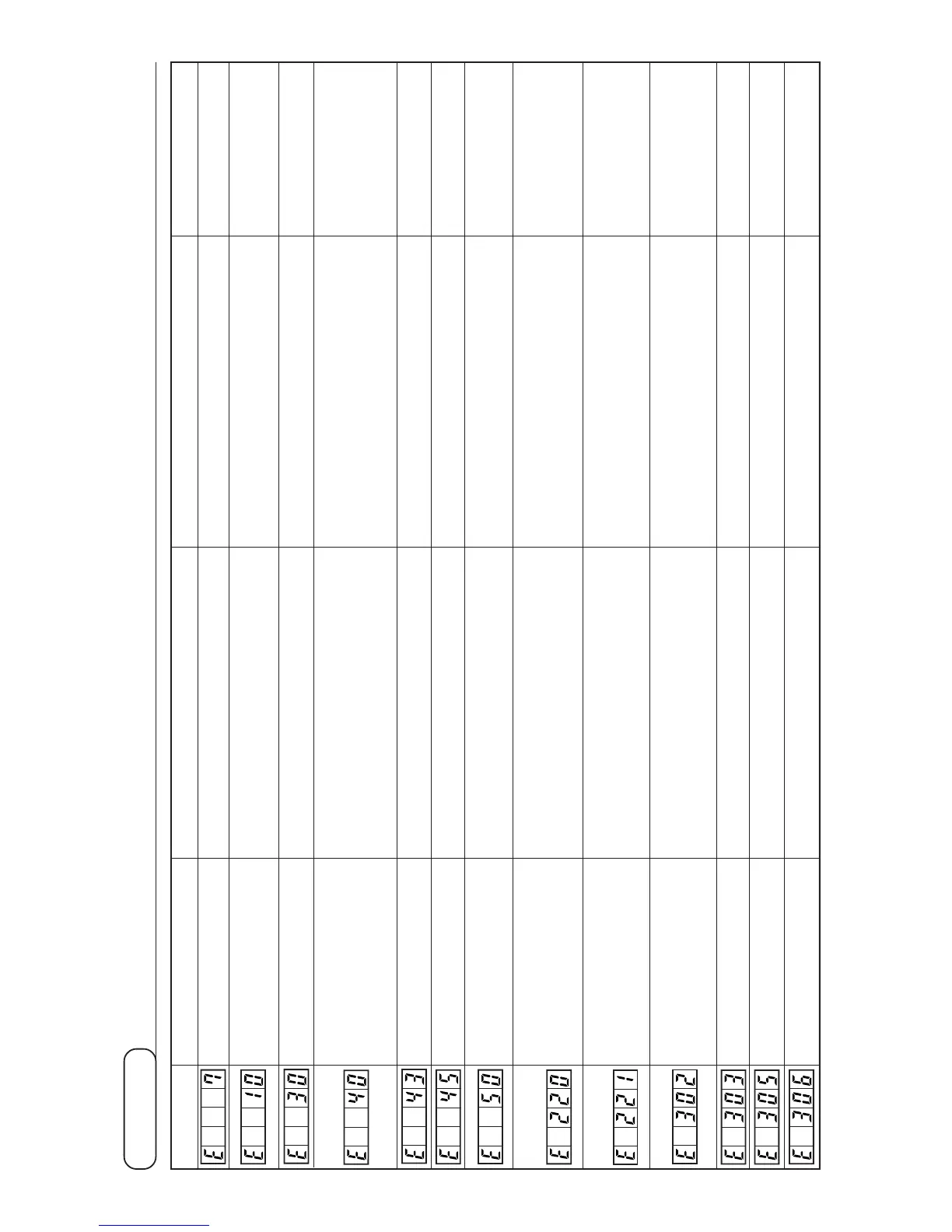

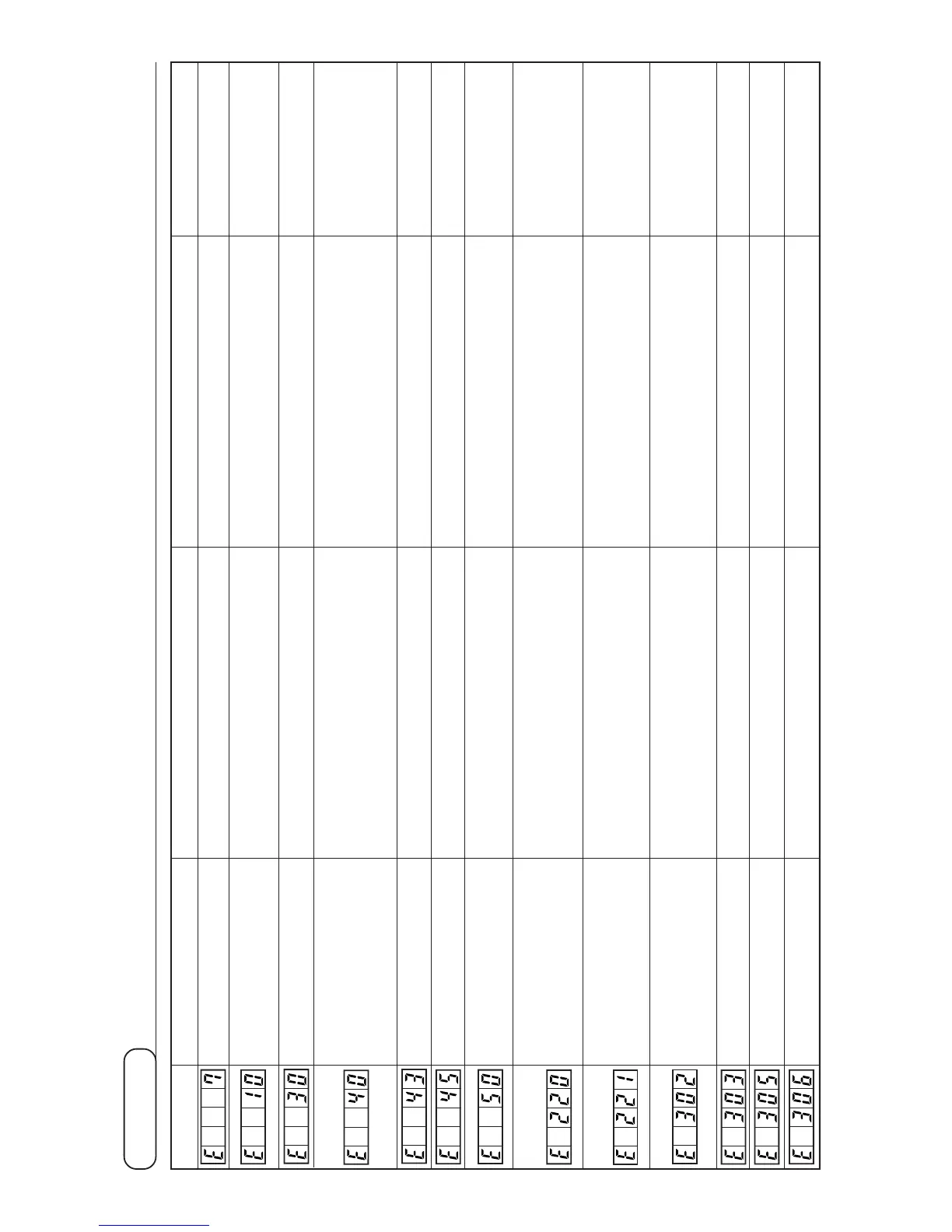

7. Error list

Indication

Name of error

Machine lock error

Pattern No. error

Needle bar UP position error

Sewing area over

Enlargement error

Pattern data error

Temporary stop

Grease replenishing time

information

Grease replenishing warning error

Head tilt error

Z phase detection error

Thread trimmer position error

Needle thread clamp position

error

Description of error

The main shaft of the sewing machine does not

rotate due to some troubles.

Back-uped pattern No. has not been registered in

the data ROM, or it is set to readout inoperative.

Pattern No. is set to “0”.

Needle bar is out of the needle UP position.

The sewing area is beyond the limit.

The sewing pitch is beyond 10 mm.

The pattern data cannot be adopted.

Temporary stop by operating the reset switch while

the sewing machine is running. (Refer to memory

switch No. 31.)

Information as to the time of replenishing the

designated places with grease

Sewing machine has stopped since the time of

replenishing the designated places with grease has

come.

Head tilt detection switch is turned ON.

Detection of the upper dead point of the sewing

machine cannot be performed.

The thread trimmer is not in the proper position.

The needle thread clamp device is not in the proper

position.

Corrective measure

Turn OFF the power switch and remove the cause

of troubles.

Press the reset switch and check the pattern No.

Check the contents of memory switch No. 201.

Turn the hand pulley to return the needle bar to its

UP position.

Press the reset switch and check the pattern and X/

Y scale rate.

Press the reset switch and check the pattern and X/

Y scale rate.

Turn OFF the power switch and check the data

ROM.

Re-start or return-to-origin after thread trimming by

means of the reset switch (For the details, refer to

the item “Using the temporary stop function”, P.29.)

Replenish the designated places with grease and

set memory switch No. 245 to “0” with the reset key.

Error can be released with the reset key when

immediate replenishing with grease cannot be

performed during sewing operation.

Immediately perform replenishing with grease and

set memory switch No. 245 to “0” with the reset key.

The sewing machine cannot be operated with the

head tilted.

Return the sewing machine head to its proper

position.

Turn OFF the power switch and check whether CN14

of SDC circuit board is disconnected or loose.

Turn OFF the power switch and check whether CN66

of FLT circuit board is disconnected or loose.

Turn OFF the power switch and check whether CN65

of FLT circuit board is disconnected or loose.

Remarks

This error is output when

max. sewing area, 30 x 40

is over. Interference of the

work clamp foot with needle

is not protected.

Refer to the item “Replenishing

the designated places with

grease” of MAINTENANCE,

p.37.

Refer to the item “Replenishing

the designated places with

grease” of MAINTENANCE,

p.37.

Loading...

Loading...