Maintenance

Inspection and maintenance schedules

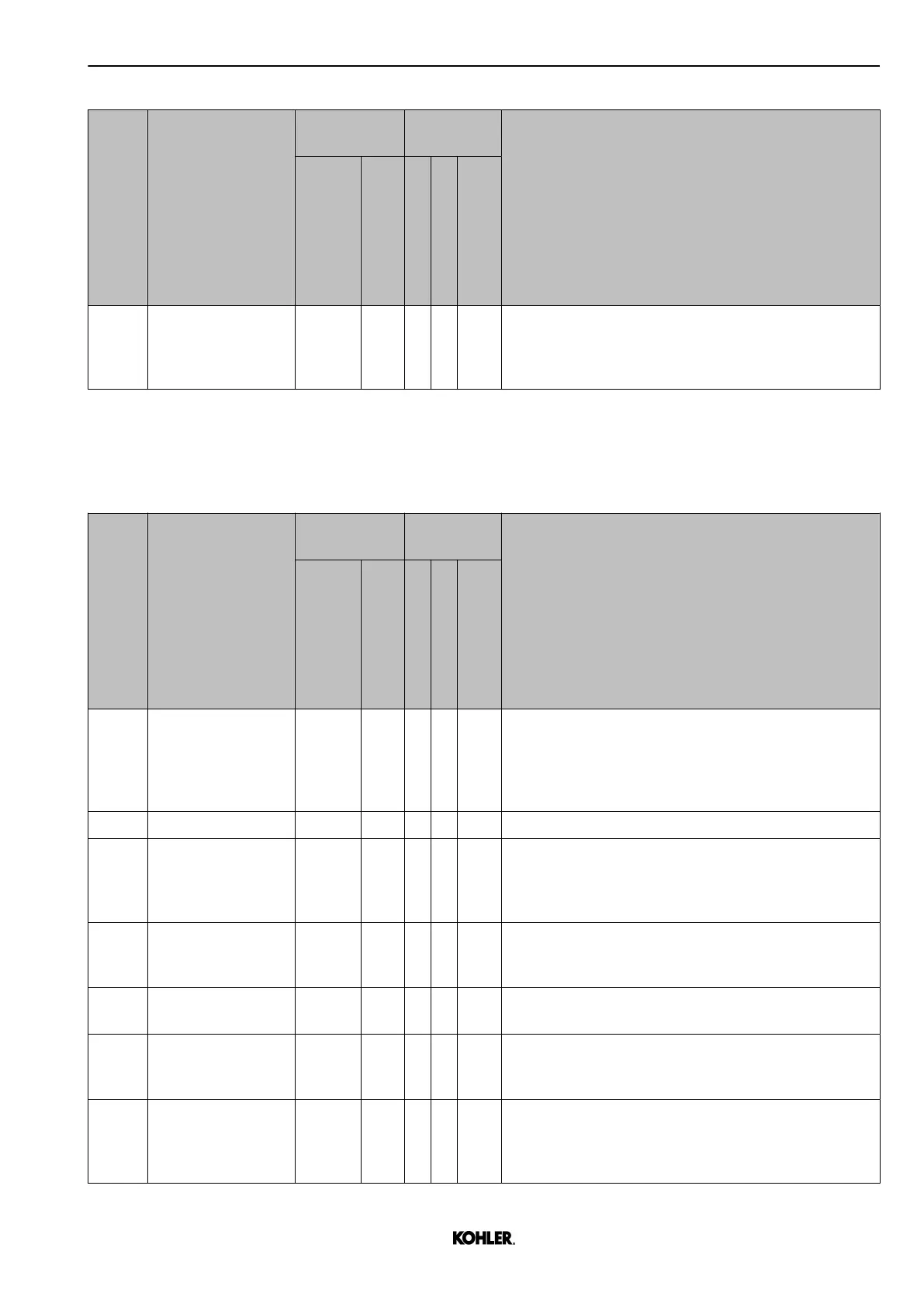

Task identification

Component

Schedule

Service

Type

Task description

Time limit (h)

Calendar limit

(year)

Replacement

Overhaul

Inspection/Clean

Repair/Adjustment

SL1-54

61

Engine by-pass

flap

3000 2Y X

Inspect overall condition including proper func‐

tioning of the flap. (For more information see:

5.12.3 Inspecting engine by-pass flap — SL1-5461

(depending on configuration), page 135.)

Tab. 16: Service level 1 — ESP — Basic maintenance - Version: 2021-07

5.4.3 Service level 2 — Engine Service, TBO 4000 hours for ESP —

Advanced maintenance - Version: 2021-07

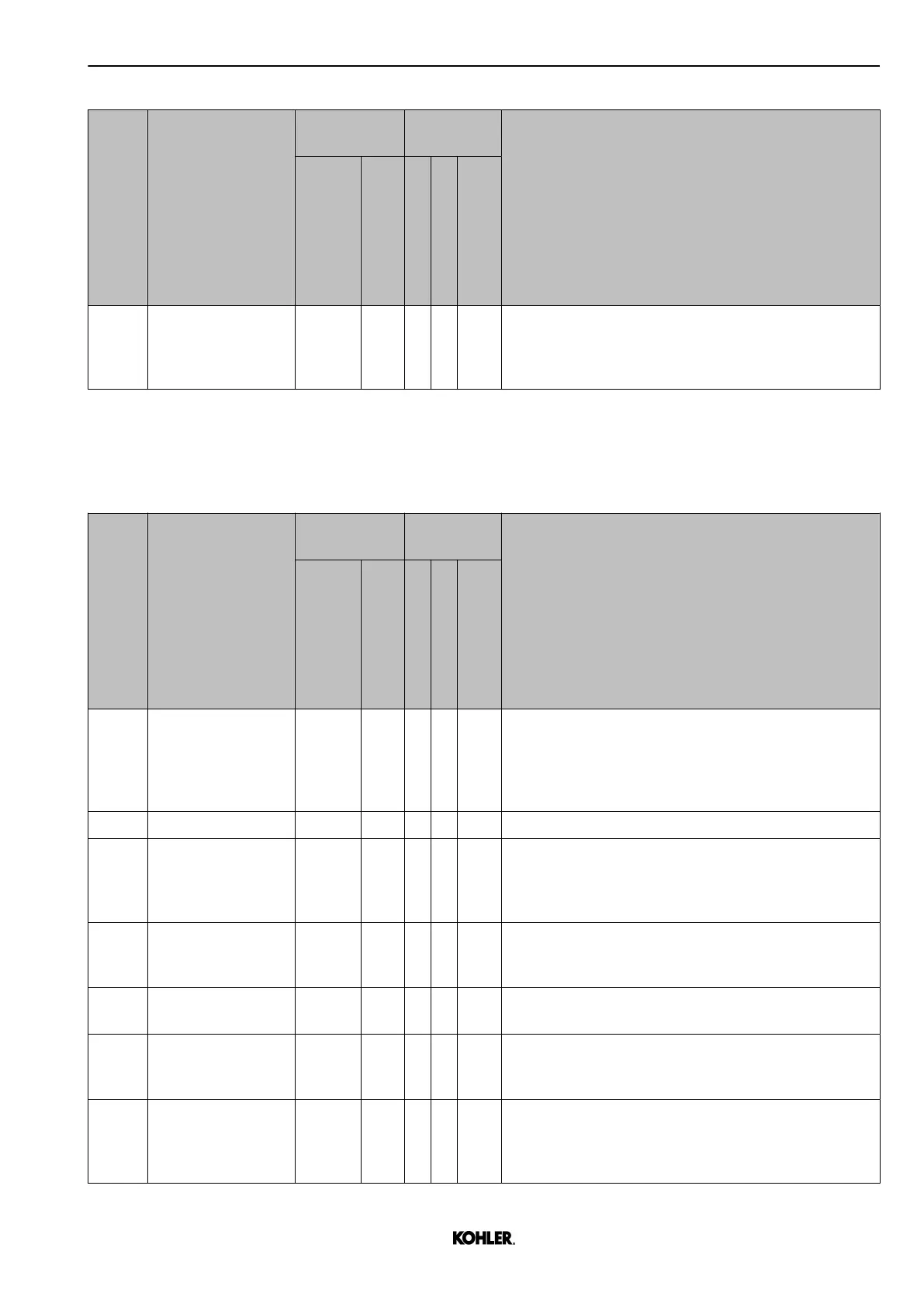

Task identification

Component

Schedule

Service

Type

Task description

Time limit (h)

Calendar limit

(year)

Replacement

Overhaul

Inspection/Clean

Repair/Adjustment

SL204 Valves clearance 2000 2Y X

Clearance check and adjustment.

First inspection at 1000 hours, second at 1500

hours.

Proceed in the same way after cylinder head repair

work.

SL205 Fuel injectors - 8Y X Replace.

SL206

Combustion cham‐

bers

- 4Y X

Done at the time the injectors are replaced. Use a

borescope to identify condition of combustion

chamber (piston crown, liner hatches, fire deck,

etc.).

SL2-13

45

Silicon oil of

torsional vibration

damper

1000 1Y X

Collect and send silicon oil sample for analysis.

SL209

HP fuel pump and

LP fuel pump

- 8Y X

Inspect for leaks. Replace pump if necessary.

SL212

Cold start oil

cooler by-pass

valve

- 18Y X

Replace.

SL213

Exhaust gas turbo‐

chargers

- 18Y X

Check overall condition (compressor blades, leaks,

connections, housings, etc.) every 4000 hours.

Replace the exhaust gas turbocharger at the indi‐

cated service interval.

KD62V12 33521030301_8_1 EN_US 2022-09

© 2022 by Kohler Co. All rights reserved.

87

Loading...

Loading...