Maintenance

Inspection and maintenance schedules

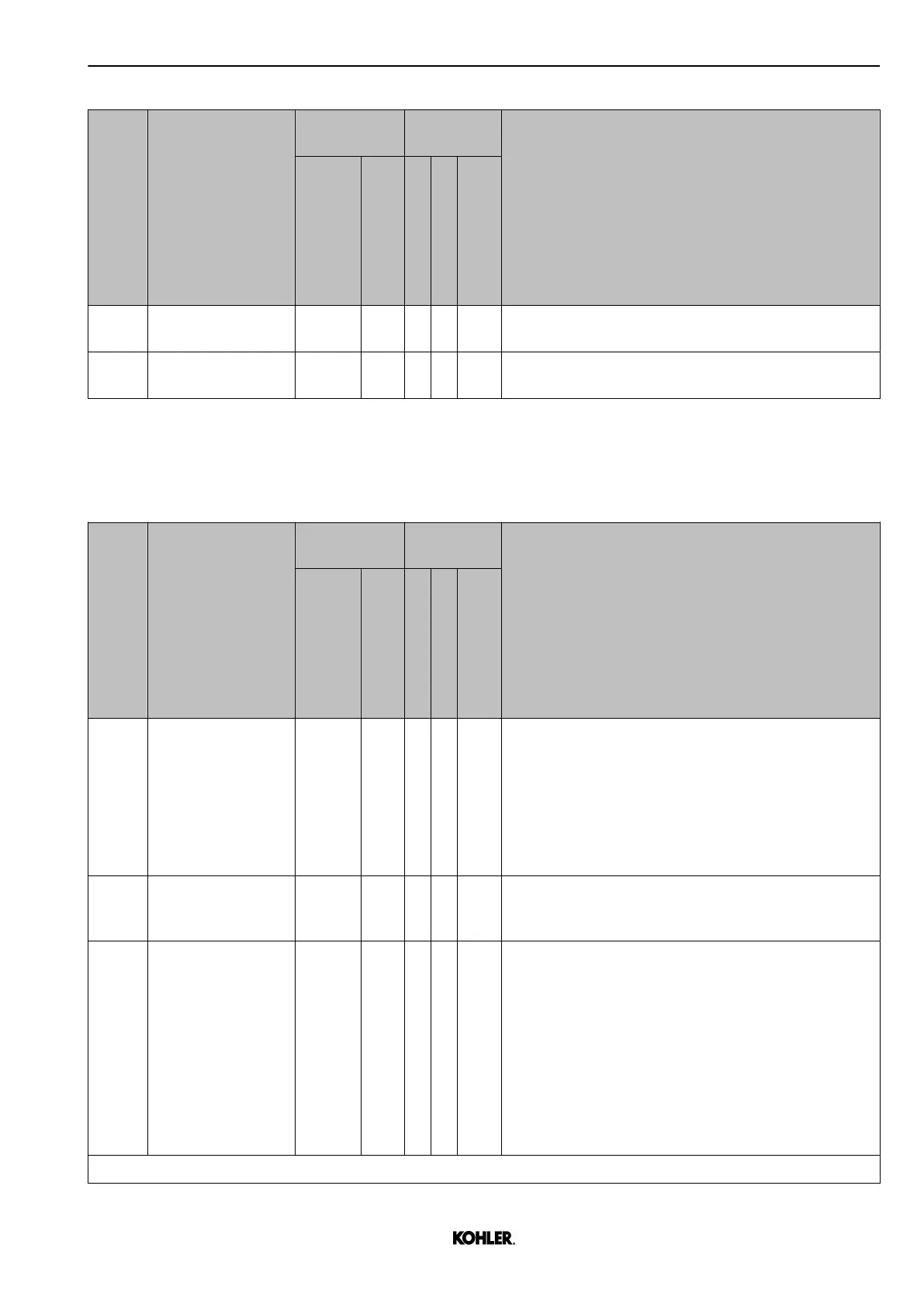

Task identification

Component

Schedule

Service

Type

Task description

Time limit (h)

Calendar limit

(year)

Replacement

Overhaul

Inspection/Clean

Repair/Adjustment

SL2-53

40

Diesel exhaust

fluid pump

7500 - X

Replace.

SL2-54

60

Engine by-pass

flap

- 8Y X

Replace.

Tab. 19: Service level 2 — PRP — Advanced maintenance - Version: 2021-07

5.4.6 Service level 1 — Engine Service, TBO 24000 hours for COP —

Engine Operation - Version: 2021-07

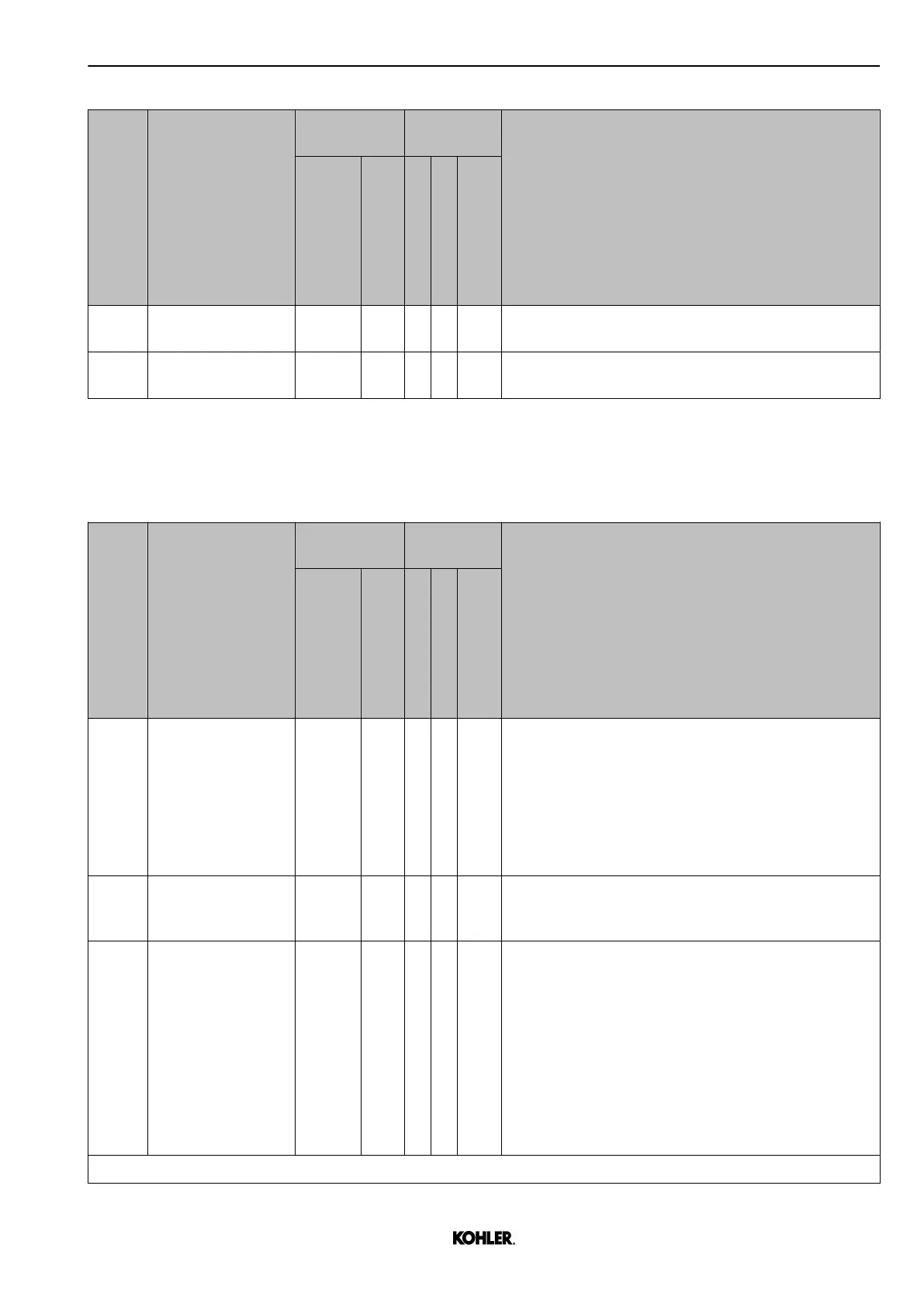

Task identification

Component

Schedule

Service

Type

Task description

Time limit (h)

Calendar limit

(year)

Replacement

Overhaul

Inspection/Clean

Repair/Adjustment

SL100 Oil sampling 250 1Y X

Collect and send oil sample for analysis every 100

hours on ESP or 250 hours (in PRP and COP applica‐

tions). If the results are not within the requested

parameters, repeat analysis at shorter intervals. In

case of use of high sulfure rate (>0.5%). No oil

Category 1 in case of K175. (For more information

see: 5.9.1 Collecting and analyzing oil sample —

SL100, page 111.)

SL120 Coolant sampling - 2Y X

Check coolant quality. (For more information see:

5.10.1 Collecting coolant sample — SL120,

page 123.)

SL122

Recommended:

First 250 service

hours for a new or

overhauled engine

250 1Y X X

Engine oil replacement. (For more information see:

5.9.6 Changing engine oil — SL101, SL121, page 118.)

Oil filters and oil filters for cooling jet replacement.

(For more information see: 5.9.4 Changing oil filters

— SL101, page 113.)

It is recommended to check the engine oil charac‐

teristics at the same time. (For more information

see: 5.9.1 Collecting and analyzing oil sample —

SL100, page 111.)

Perform all check before starting and perform a

test run.

Without centrifugal oil filter

KD62V12 33521030301_8_1 EN_US 2022-09

© 2022 by Kohler Co. All rights reserved.

93

Loading...

Loading...