MAINTENANCE MAINTENANCE PROCEDURE

4-71

REMARK

Operate the machine after halting for more than 5 minutes to eliminate bubbles in the oil inside the tank.

12. Check for oil leakage and wipe off any spilled oil.

CHANGE OIL IN SWING MACHINERY CASE 4

WARNING

Parts and oil are at high temperature immediately after the engine is stopped and may cause serious

burns. Wait for the oil temperature to go down before performing this operation.

q Refill capacity: 20 liters

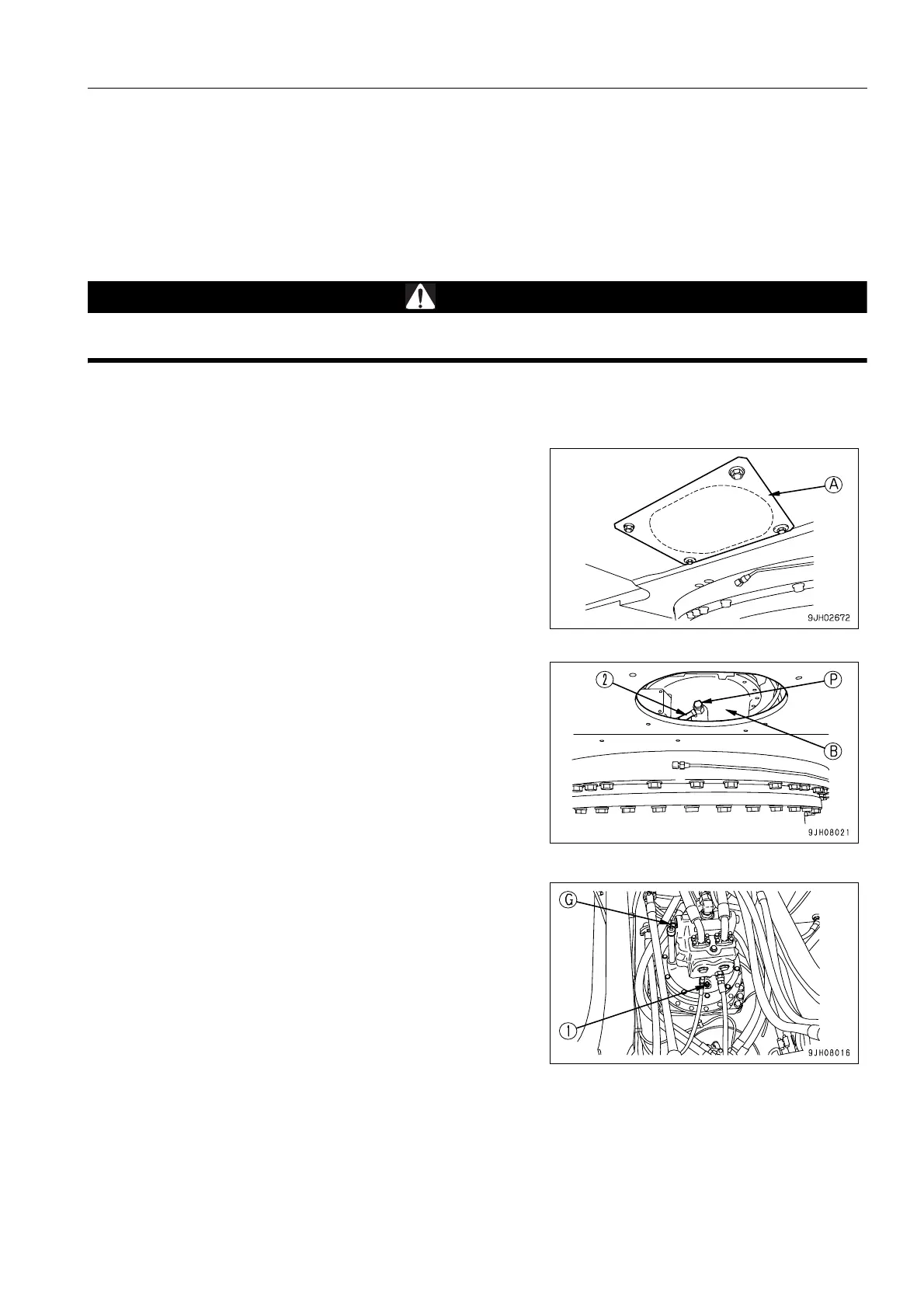

1. Remove cover (A) of the inspection hole.

(Only demolition specification machine)

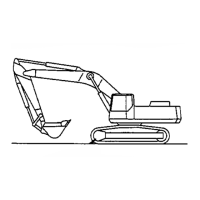

2. Set a container under drain valve (P) under the machine

body to catch the oil.

3. Loosen drain valve (P) under the body, drain the oil, then

tighten the drain valve again.

q When draining the oil, first pull hose (2) out from

inspection hole (B), then turn the drain valve to the

OPEN position.

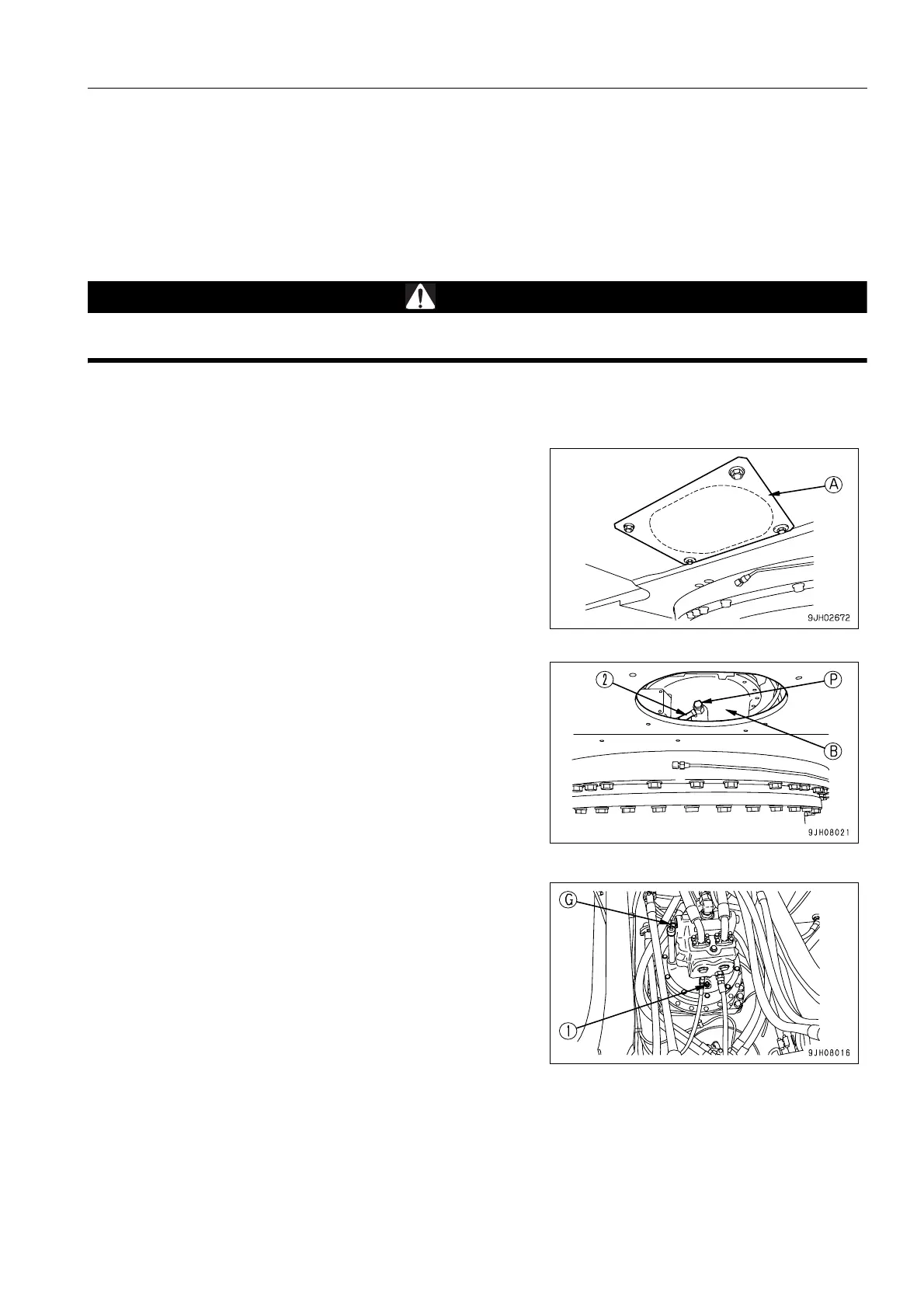

4. Remove dipstick (G) and air bleeding plug (1).

5. Add the replacement amount of oil through the insertion

guide for dipstick (G).

6. Check the oil level. For details, see “CHECK OIL LEVEL

IN SWING MACHINERY CASE, ADD OIL (4-65)“.

7. Install air bleed plug (1).

Loading...

Loading...