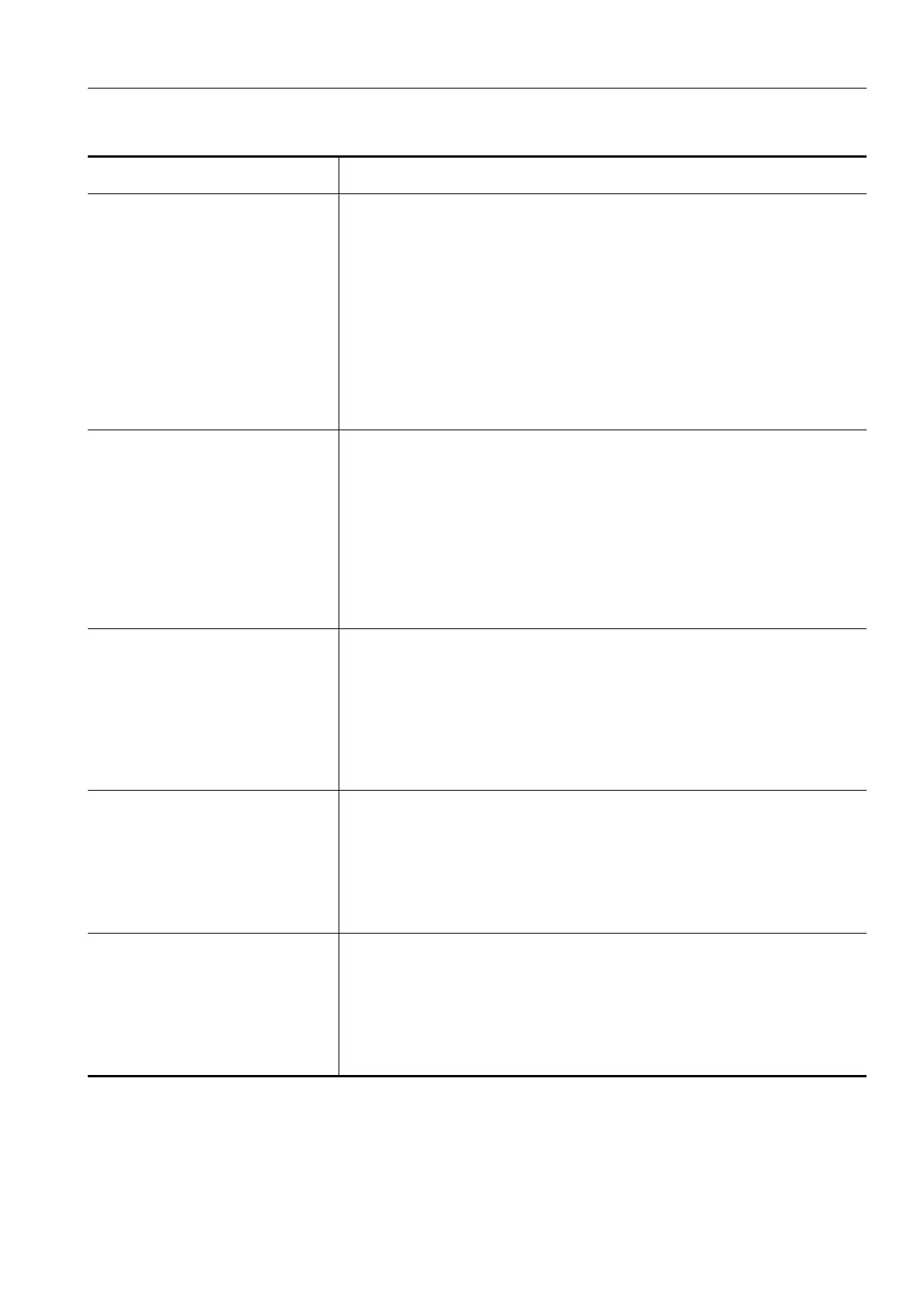

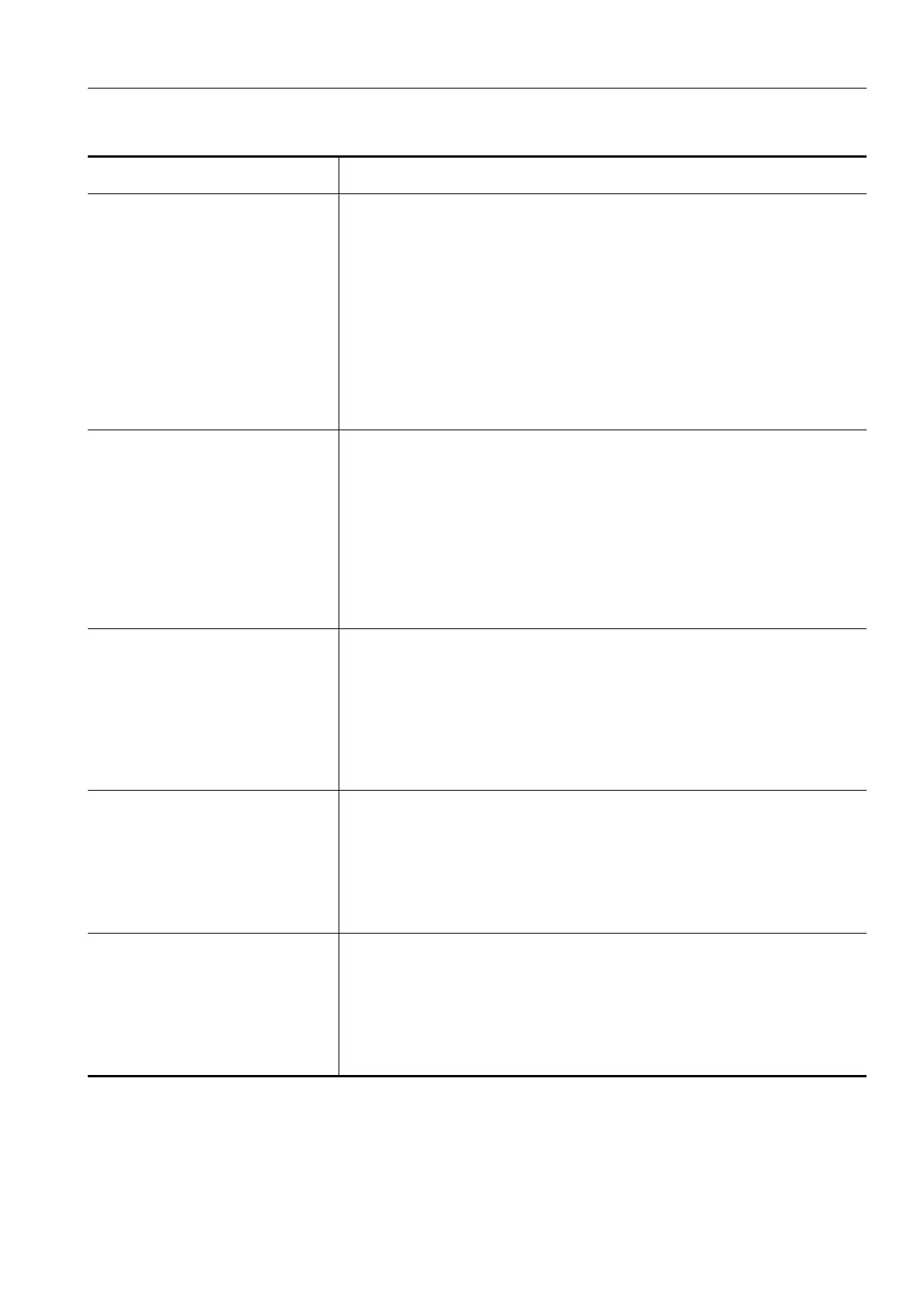

OPERATION 3.25 TROUBLE SHOOTING

305

3.25.2 HYDRAULIC SYSTEM

Problem Probable cause

Poor hydraulic system perfor-

mance

● Hydraulic oil not at operating temperature.

● Engine speed too low.

● Reservoir low on oil

● Restrictions in lines

● Cooling circuit, pump control system and/or pilot control circuit

defective.

● Internal leakage (control blocks, valves or power units.)

● Pressure lines twisted or kinked

● Spool not in full stroke.

● Relief valve defective, or out of adjustment.

● Worn cylinders.

● Defective hydraulic pump.

Excessive oil temperature

● Low oil level

● Incorrect viscosity or type of oil

● Hydr. oil cooler clogged with dirt.

● Oil cooler fan defective or wrong speed.

● Cooling circuit defective

● Pump control system defective

● Spool not in full stroke.

● Internal leakage (control blocks, valves or power units)

● Worn pump components

● Job conditions (high temperature of materials being handeld)

Jerky motion of power cylinders

● Piston rod bent

● Piston sticking

● Inside diameter of cylinder tube partially increased or scored

● Air in control circuit

● Oil too cold

● Valve spool sticking, centering springs defective

● Pump and/or engine control system defective

● Valve of power circuit defective

Noise when slewing

● Inssufficient lubrication of swing ring gear and/or slewing connection.

● Slewing connection mounting bolts loose

● Drive pinion worn

● Swing gear bearings worn

● Sun gear or planetary pinions worn

● High pressure circuit valves defective

● Anti-caviation valves sticking

Excessive oil foaming

● Air in hydraulic system

● Poor quality oil

● Excessive by-passing of oil over relief valves

● Pressure hoses badly twisted or kinked

● Restricted oil flow due to foreign matter

● Breather on the reservoir clogged.

● Relief valve improperly adjusted

Loading...

Loading...