MAINTENANCE 4.12 EVERY 1000 OPERATING HOURS OR EVERY 6 MONTH

479

4.12.3 PTO’S (PUMP DISTRIBUTOR GEARS), SWING GEARS AND TRAVEL

GEARS - OIL SAMPLE ANALYSIS

The oil sample analysis gives information about the grade of con-

tamination and aging of the gear oils. Refer to the tables below for

limits of contamination.

Oil drain plugs, illustration Z25250

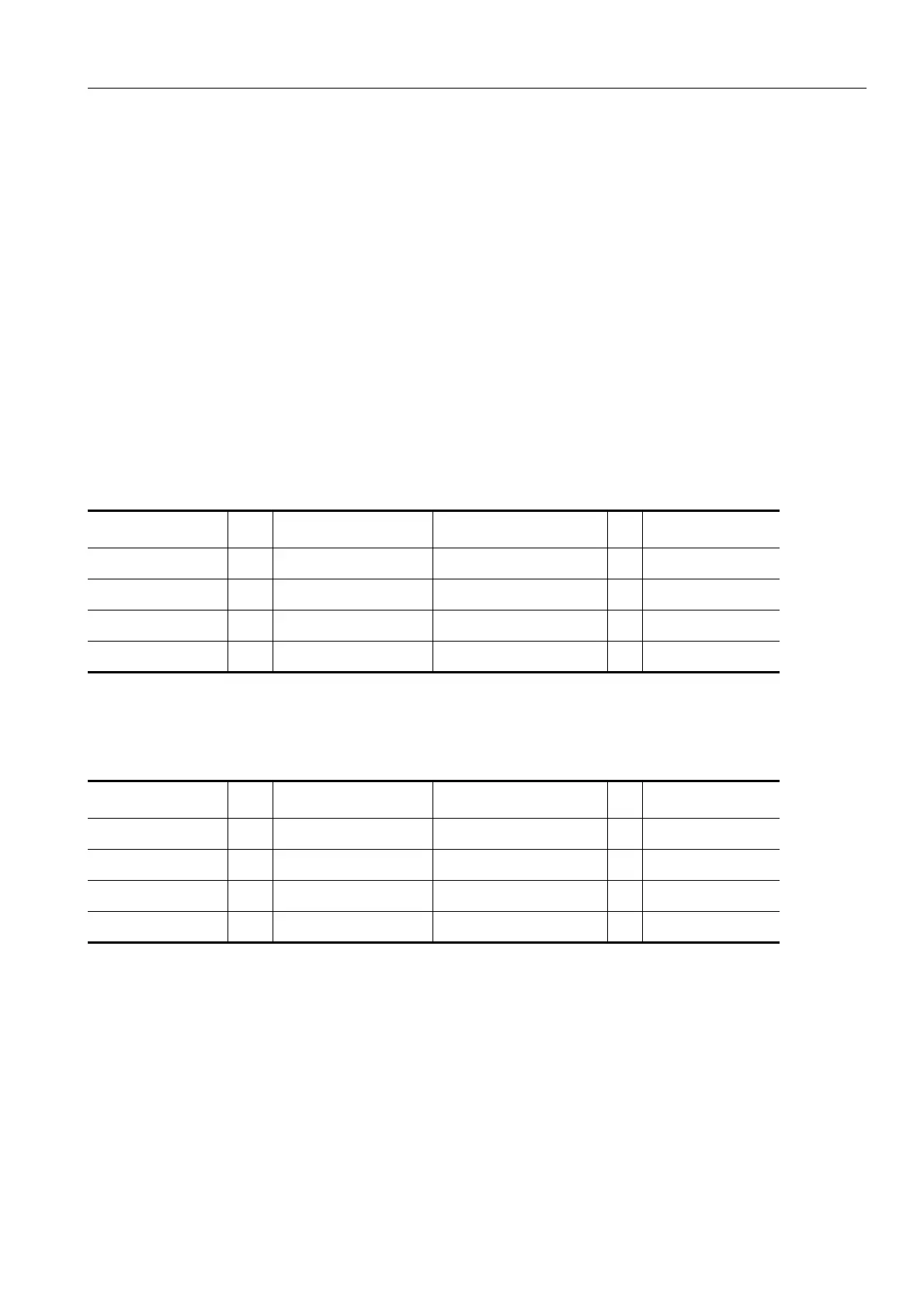

PTO (PUMP DISTRIBUTOR GEAR)

(Oil contamination)

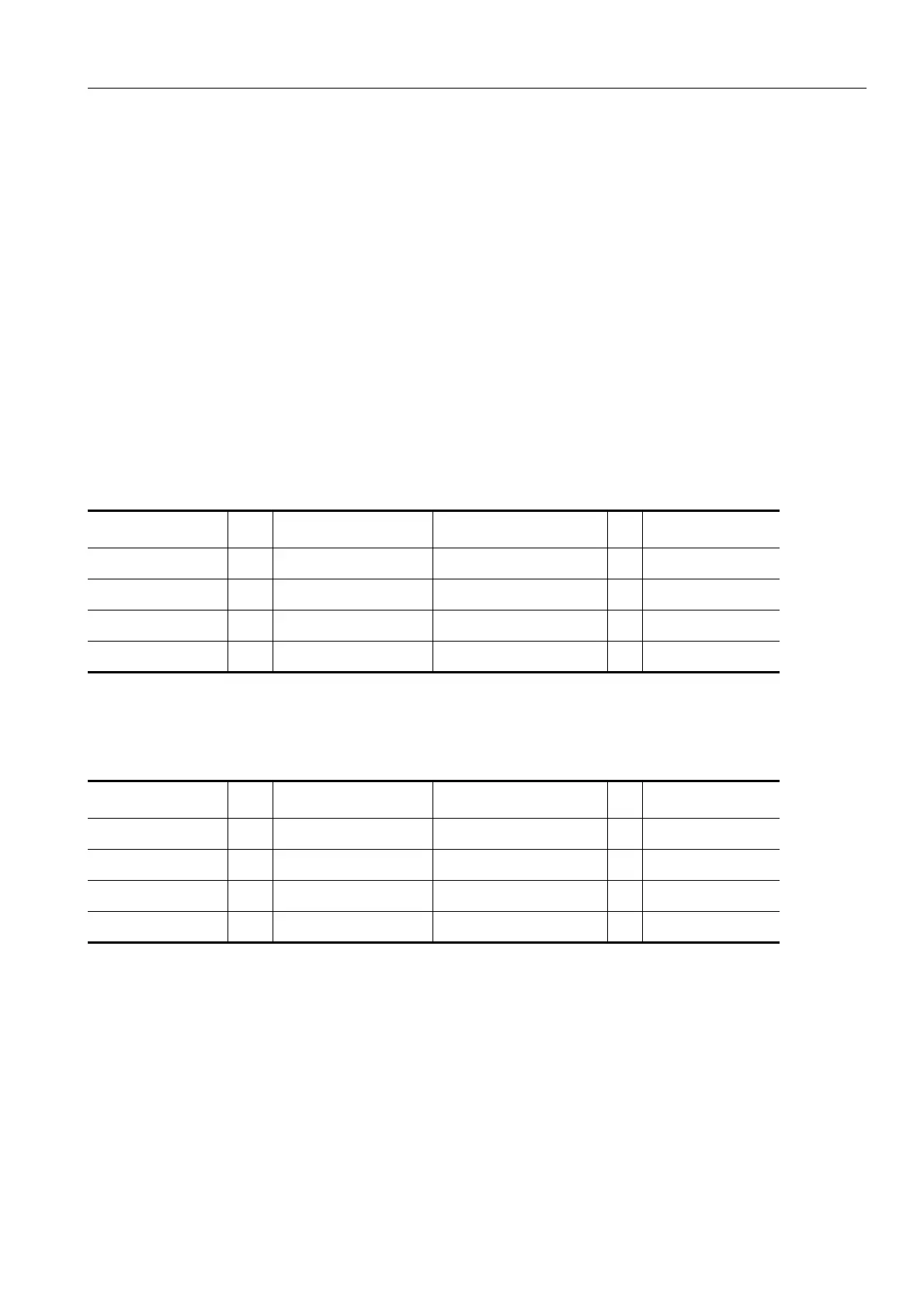

SWING GEARS AND TRAVEL GEARS

(Oil contamination)

OTICE

If the grade of contamination approaches to the “critical” val-

ues in the above tables, change the gear oil. However, the

regular oil changes must be carried out every 3000 operating

hours or once a year, whichever occurs first.

(1) PTO (Pump distributor gears)

(2) Swing gears (I and II)

(3) Travel gears

Element Normal Increased Critical

Iron < 100 ppm 100 - 300 ppm > 300 ppm

Copper < 10 ppm 10 - 20 ppm > 20 ppm

Chromium < 5 ppm 5 - 15 ppm > 15 ppm

Silicon < 40 ppm 40 - 60 ppm > 60 ppm

Element Normal Increased Critical

Iron < 400 ppm 400 - 700 ppm > 700 ppm

Copper < 25 ppm 25 - 60 ppm > 60 ppm

Chromium < 5 ppm 5 - 15 ppm > 15 ppm

Silicon < 40 ppm 40 - 60 ppm > 60 ppm

Loading...

Loading...