MAINTENANCE EVERY 250 OPERATING HOURS

7-51

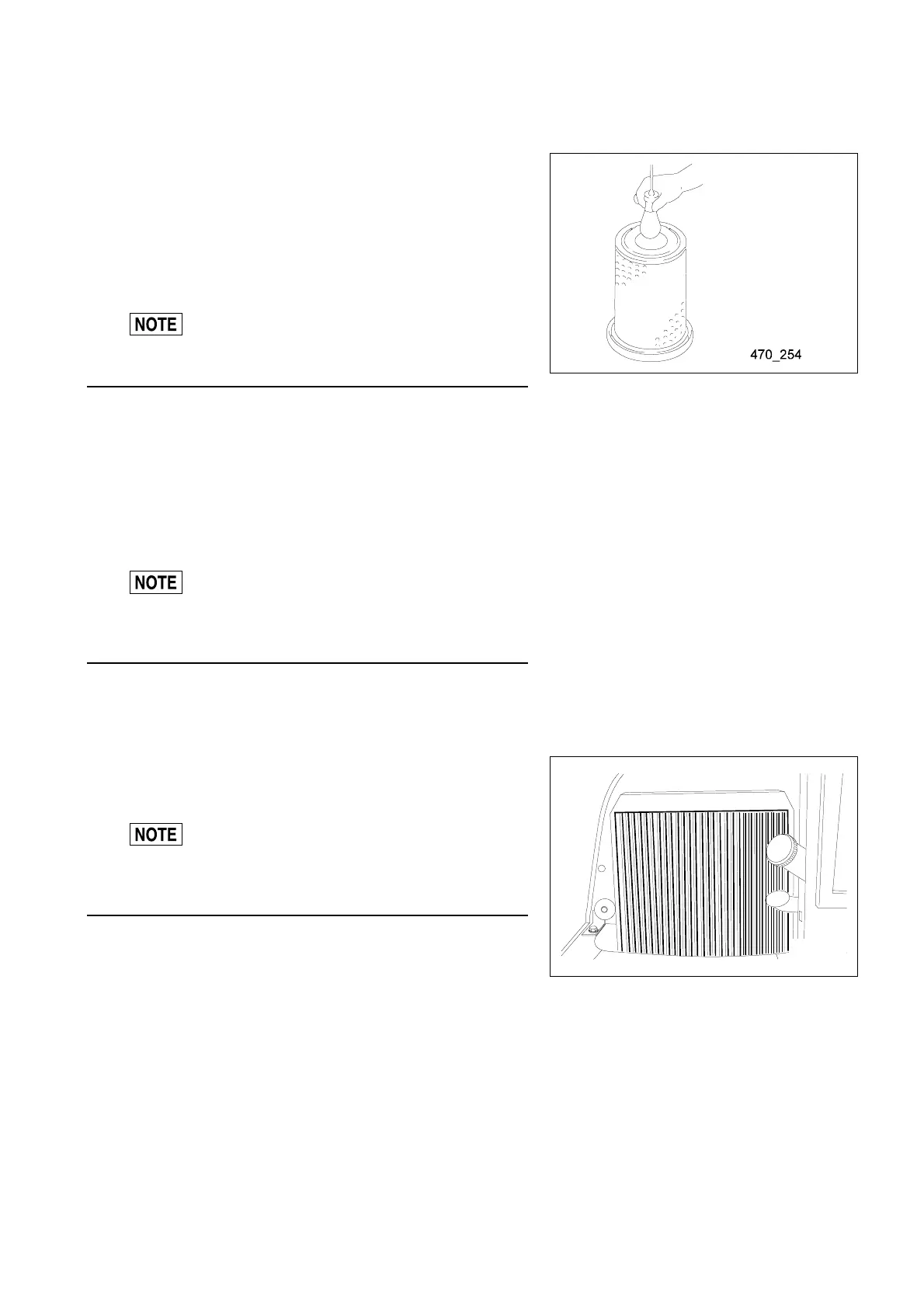

CHECKING THE FILTER CARTRIDGE

Usually, it is required to check each air filter cartridge before it is

re-installed. For this purpose, insert a lamp into the cartridge

and visually check the filter paper against the transmitted light. If

you detect small holes or spots on which the paper is thin, the in-

sert is defective and must be replaced.

Check filter cartridges for damaged seals.

☞

• Also new filter cartridges must be checked before they are

assembled.

ASSEMBLING THE AIR FILTER CARTRIDGE

1. Check the safety filter for proper fit.

2. Insert the filter cartridge into filter housing in such a way that

the seal of the insert locks firmly on the collar of the housing

rear panel.

3. Assemble the air filter cap.

☞

• If the control lamp lights up again after a short time, you

must replace both, the air filter cartridge and the safety fil-

ter.

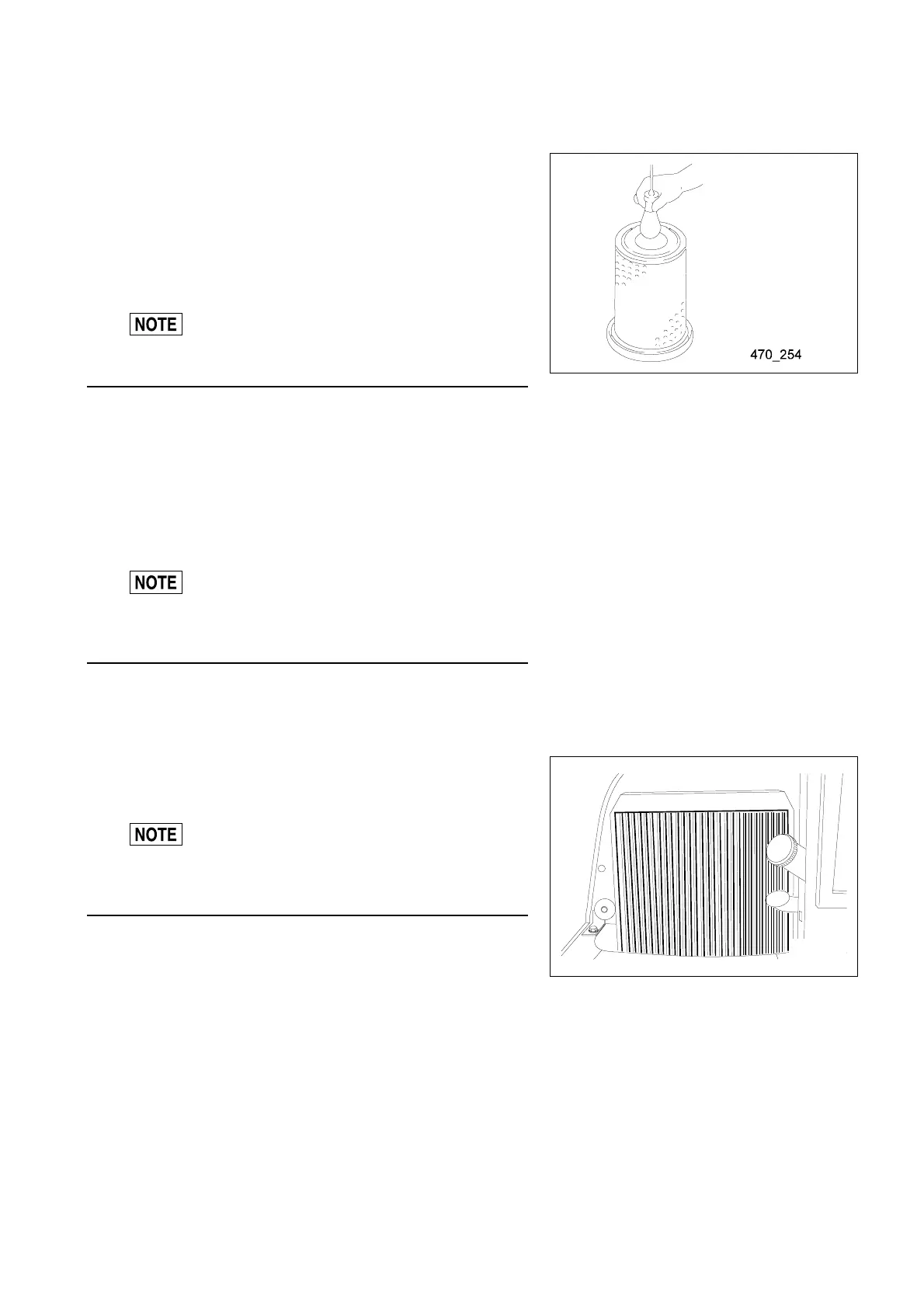

CLEANING THE RADIATOR SEGMENTS

The radiator segments must be checked daily and cleaned with

compressed air, if required.

☞

• Do not hold the compressed air nozzle or water nozzle too

close to the radiator segments. Do not use a scrubber for

cleaning since the plates may be damaged.

75_250

Loading...

Loading...