SAFETY MEASURES DURING MAINTENANCE

3-22

SAFETY MEASURES DURING MAINTENANCE

PERSONNEL

Do not service or repair the machine unless you are an appropri-

ately qualified technician or have been appropriately instructed

by a qualified technician.

PRIOR TO START OF MAINTENANCE MEASURES

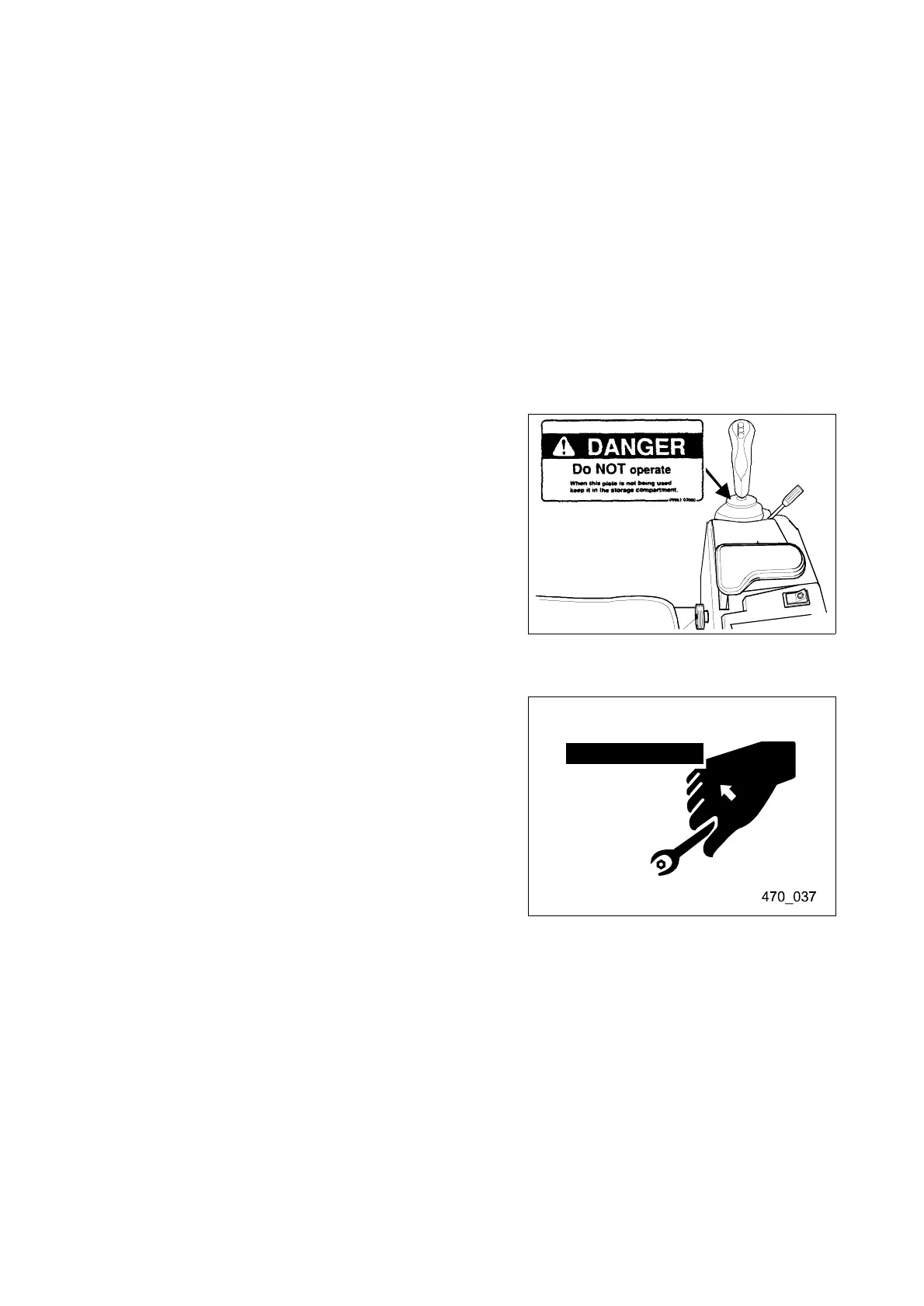

WARNING SIGN

While the machine is being serviced, the engine must not be

started and the control elements must not be actuated without

prior agreement, since this could cause accidents with serious

injury.

Always attach the warning sign to the control lever for the work

hydraulic system to warn other persons that work is being per-

formed on the machine. If required, put up additional warning

signs around the machine.

You may purchase these warning signs from your Komatsu deal-

er.

TOOLS

Only use tools which are suitable for the task you want to carry

out. If you use damaged or makeshift tools or tools which are of

inferior quality, injuries may occur.

SAFETY-RELATED PARTS

The quality of these parts is subject to normal wear and tear. For

this reason, replace safety-related parts by new ones at regular

intervals, regardless of whether they are defective or not.

Safety-related parts are:

Fuel system: fuel hose, overflow hose, and tank cap

Hydraulic system: all hydraulic hoses

Immediately replace defective parts, even if the interval for re-

placement has not elapsed.

Replace hydraulic hoses every 6 years.

75_060G

Loading...

Loading...