MAINTENANCE EVERY 500 OPERATING HOURS

7-54

BLEEDING THE FUEL SYSTEM

• Fuel in the injection system is under pressure.

Use goggles and rubber gloves if you work on the injec-

tion pump. If you are hit by a high-pressure fuel stream,

immediately seek medical attention.

1. For maintenance operations, park and secure machine as

described in chapter "Preparing the Machine for Mainte-

nance".

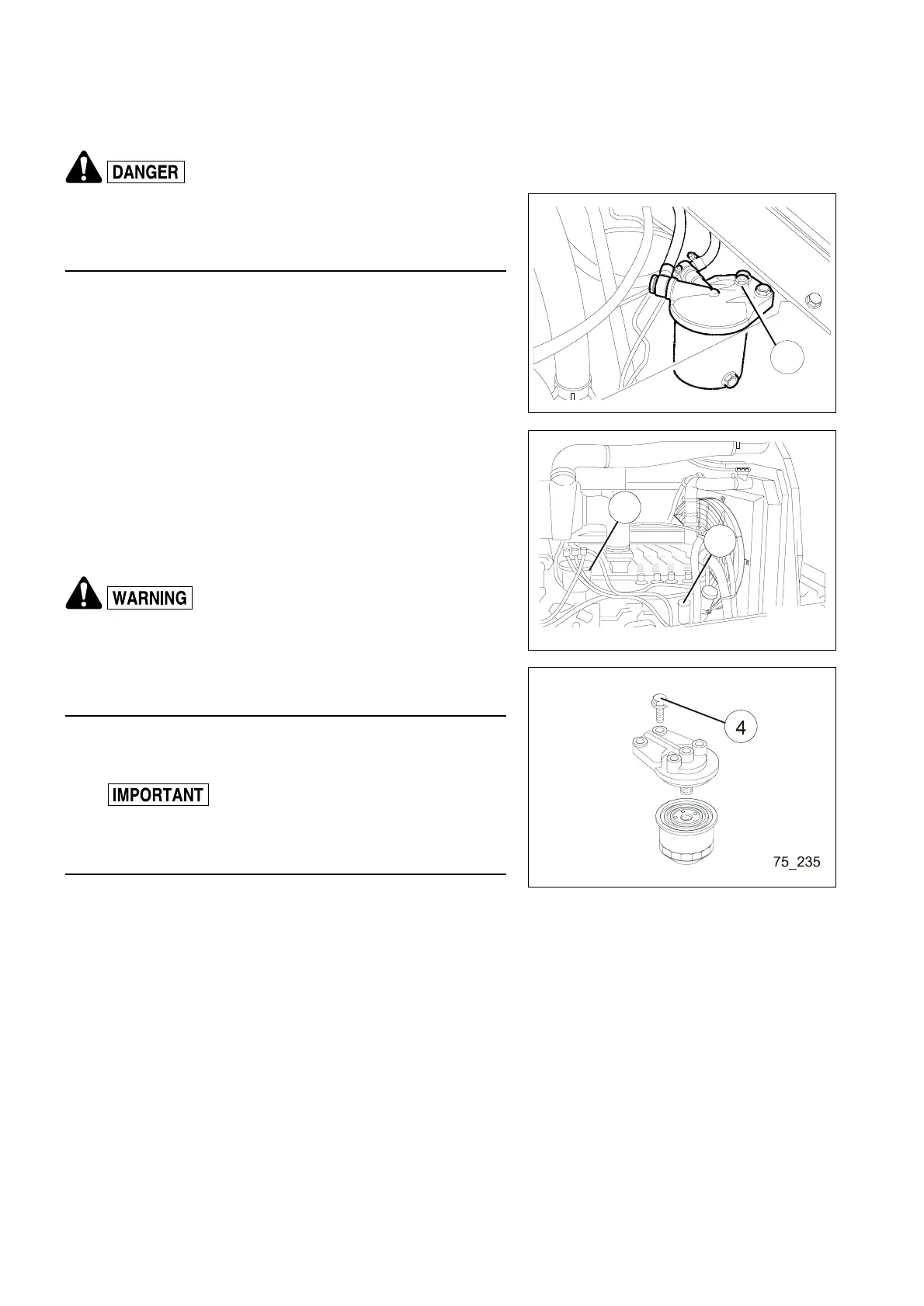

2. Loosen the vent screw (1) at the water separator.

3. Unlock the fuel pump (2) by pressing the cover down and

swivelling it out of the way.

4. Operate fuel pump until bubble-free fuel leaks out at the vent

screw.

5. Re-tighten the vent screw.

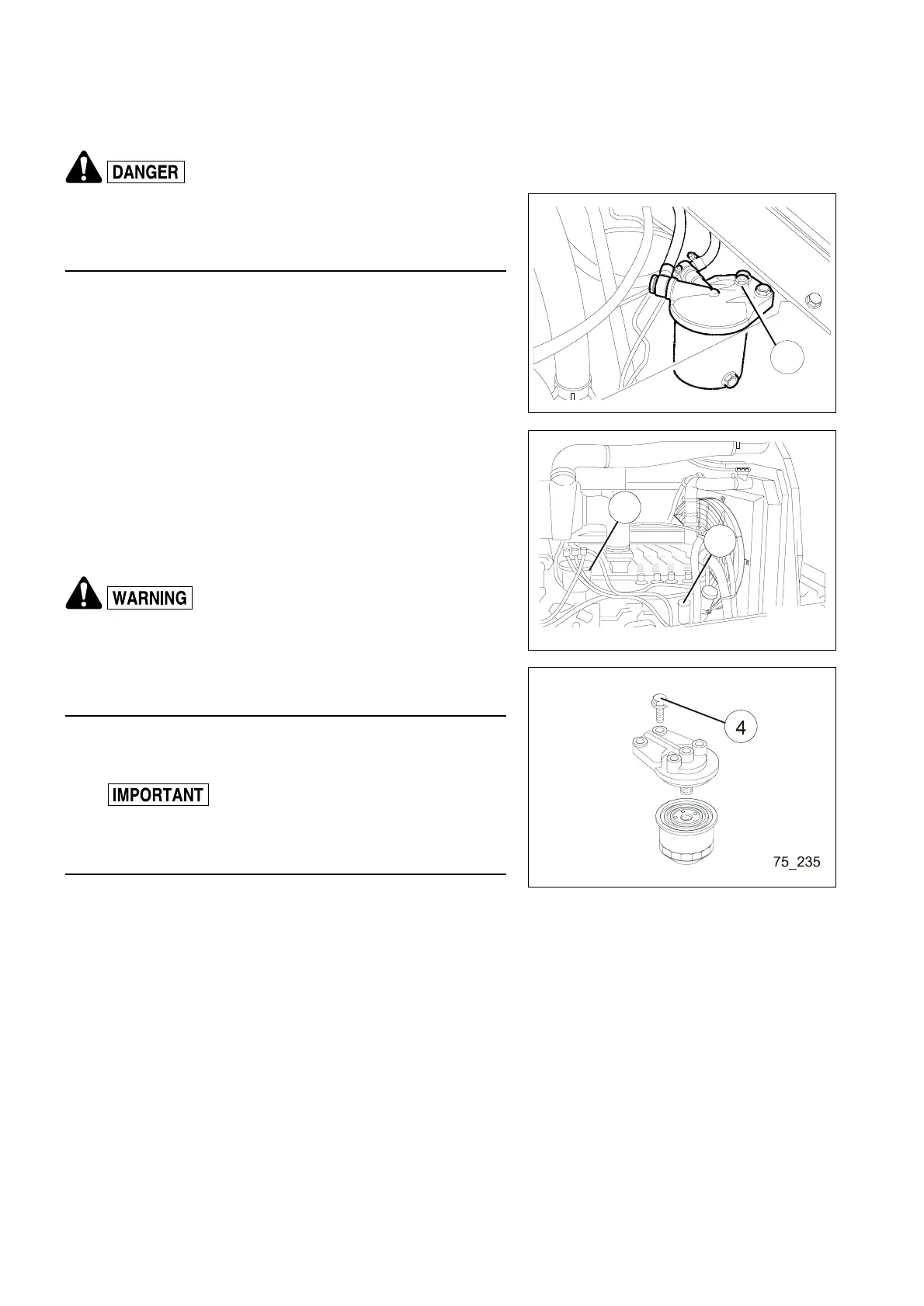

6. Loosen the vent screw (4) at the fuel filter (3).

7. Operate the fuel pump until bubble-free fuel leaks out at the

vent screw.

8. Re-tighten vent screw.

9. Re-lock the cover of the fuel pump.

• Danger of injury! When the engine is running, you may

hurt yourself on the movable components inside the en-

gine room.

Do not perform any operation in the engine room with the

engine running.

10. Start up the engine and bleed the lines, one after the other,

while engine is running until the engine is running regularly.

☞

• If the fuel system has run empty during driving, or if re-

pairs or maintenance operations are to be performed, it is

necessary to bleed the system.

1

75_233

75_234

2

3

Loading...

Loading...