MAINTENANCE AND REPAIR

Operating instructions • Load Carrier • 505410638-02 • 07/2019

111

The aim of maintenance is:

○ that the commissioned trailer is kept

operating safely and performing prop-

erly during use,

○ to prevent downtimes,

○ to keep the costs of operational readi-

ness reasonable and financially justifi-

able,

○ and to limit unavoidable repair ex-

penditures.

10.2.1 Regular checks and functional

testing

To ensure that the trailer is in proper oper-

ating condition, the safety-related equip-

ment must be checked regularly for proper

function, its effectiveness must be ensured

and the recurring inspections must be per-

formed.

► Prior to starting each trip, perform a

departure check (see "7.1 Commissioning

before each trip", pg.88).

► Perform legally prescribed general in-

spections punctually.

► Observe the intervals and instructions

for testing and maintenance of the

supplied components (e.g. axles) con-

tained within the respective supplied

operating instructions.

► Report any detected safety defects:

○ Take the trailer out of operation if oper-

ational safety is not ensured.

○ When there is a change of shift, inform

the colleague starting the next shift

about observed defects and implemen-

ted measures.

► Perform the following checks and func-

tional testing at the intervals pre-

scribed:

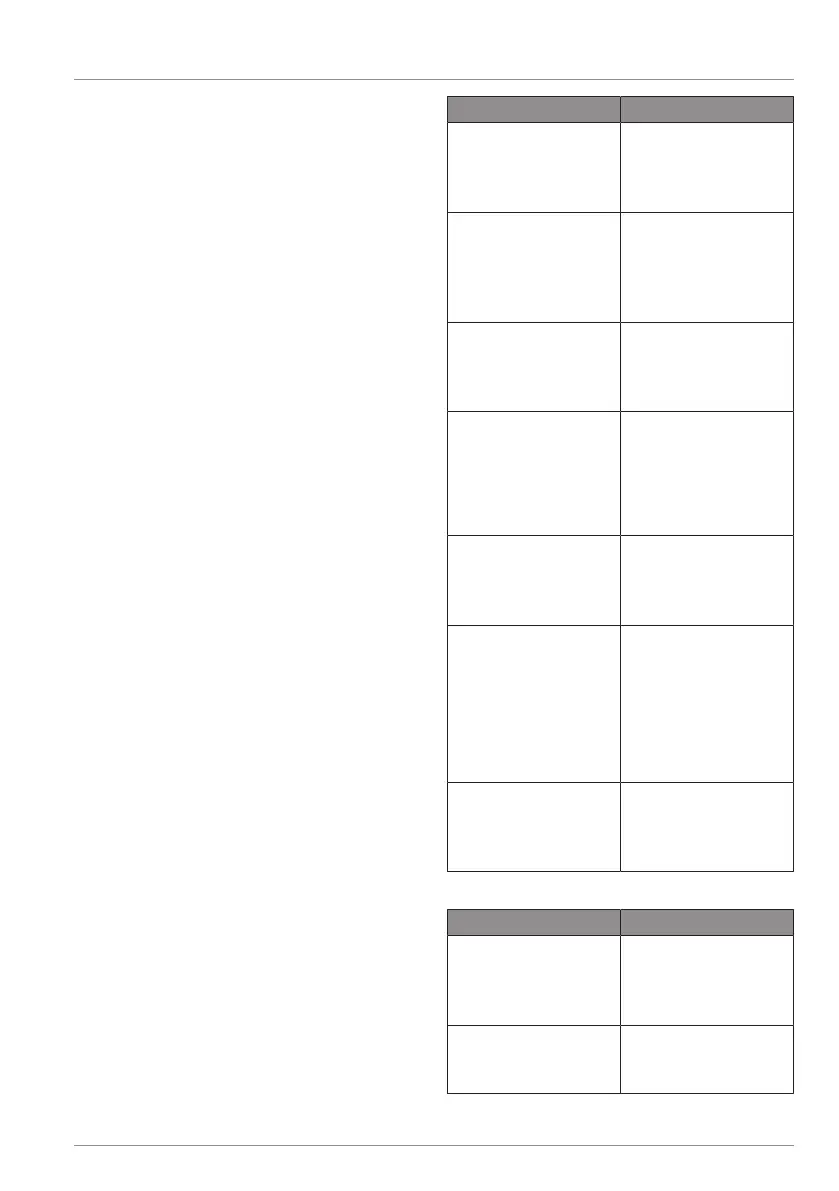

Daily, or before every journey

Component Inspection

Rear underrun pro-

tection/side collision

protection

► Visually inspect

for wear, dam-

age and proper

attachment.

Compressed air tank

► Actuate the wa-

ter drain valve

(see "5.8 Draining

the compressed

air tanks", pg.35).

Lighting equipment

► Visually inspect

to make sure it

is working prop-

erly.

Hydraulic rear width

expansion (optional)

Visually inspect for

wear, damage, leak-

age and proper at-

tachment, perform a

functional test on the

pump.

Coupling ring

► Visual check for

wear, damage

and proper at-

tachment.

Draw fork

► Visual check for

wear, damage

and proper at-

tachment.

► Lubricate the

spring bolt on

the base shoe.

Drawbar wale

► Visual check for

wear, damage

and proper at-

tachment.

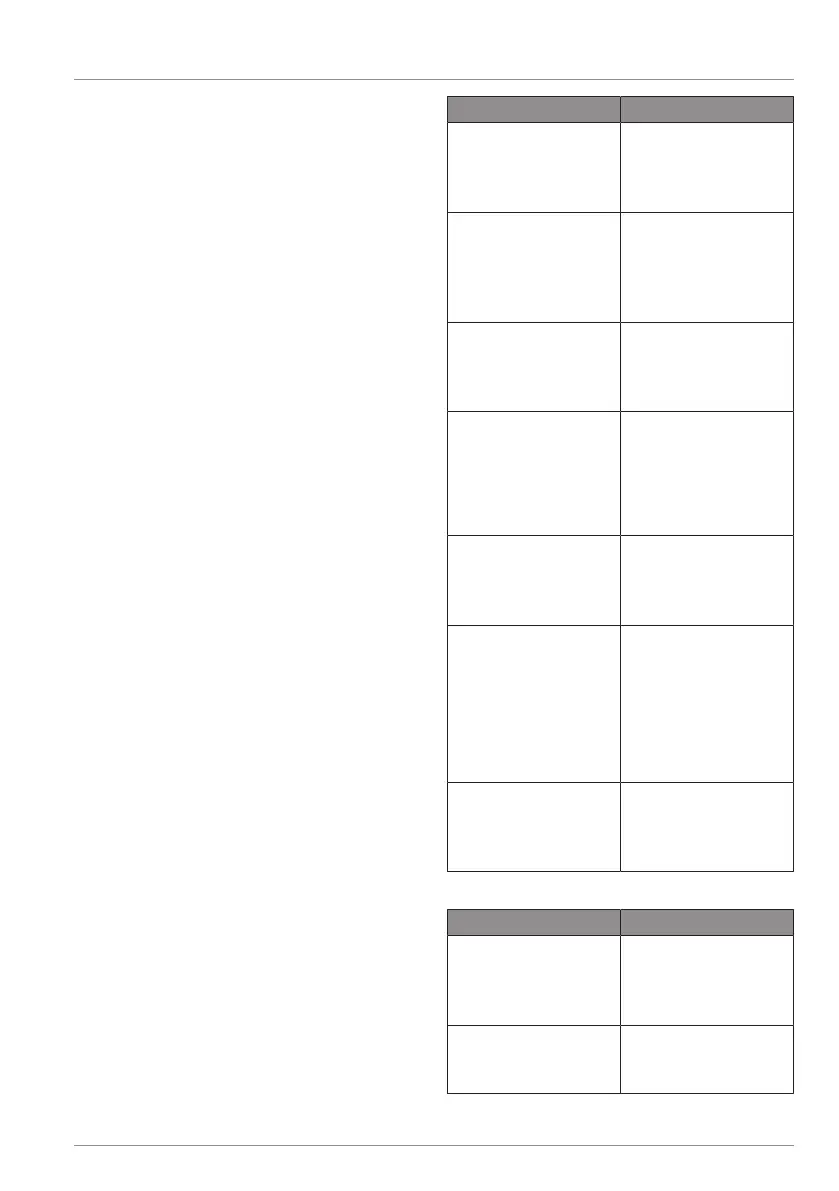

Weekly

Component Inspection

Compressed air tank

► Perform a visual

inspection for

wear and dam-

age.

Tyres

► Check the tread

depth and tyre

pressure

Loading...

Loading...