MAINTENANCE AND REPAIR

112

Operating instructions • Load Carrier • 505410638-02 • 07/2019

► Go to an authorised specialist work-

shop if defects have been found.

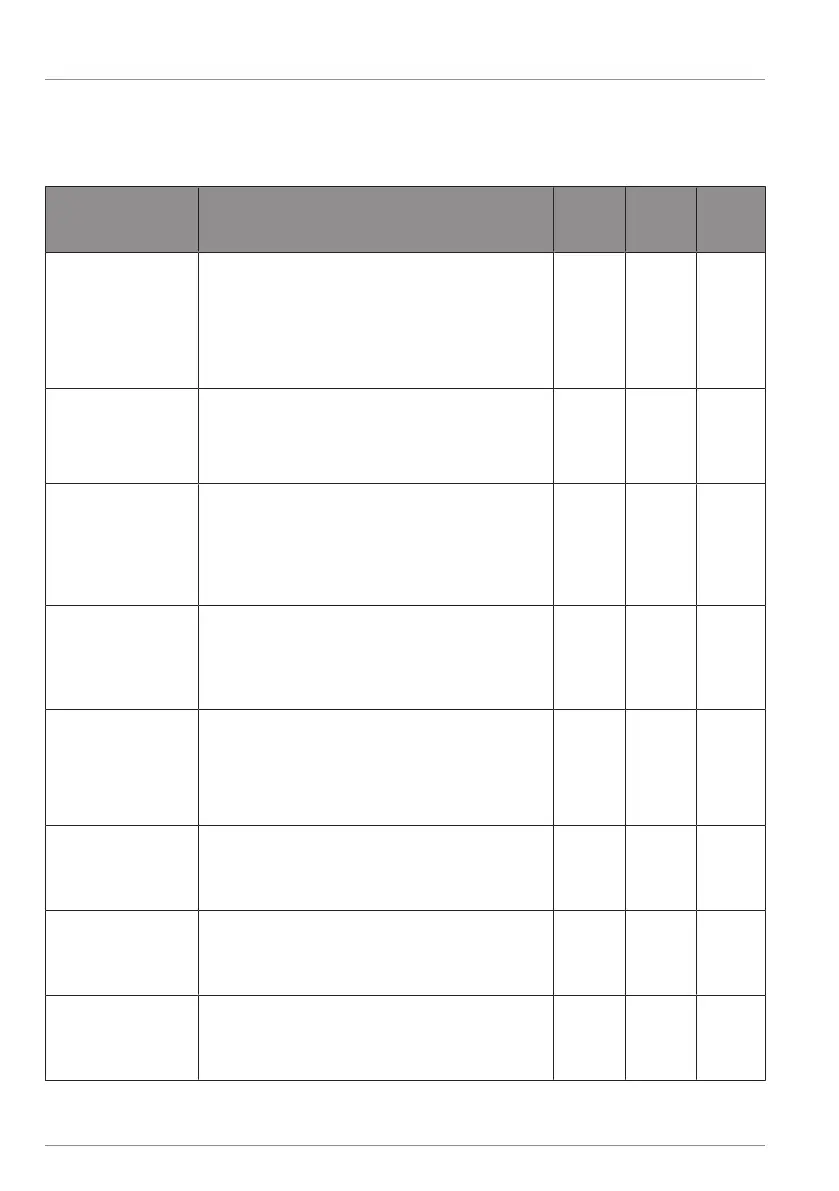

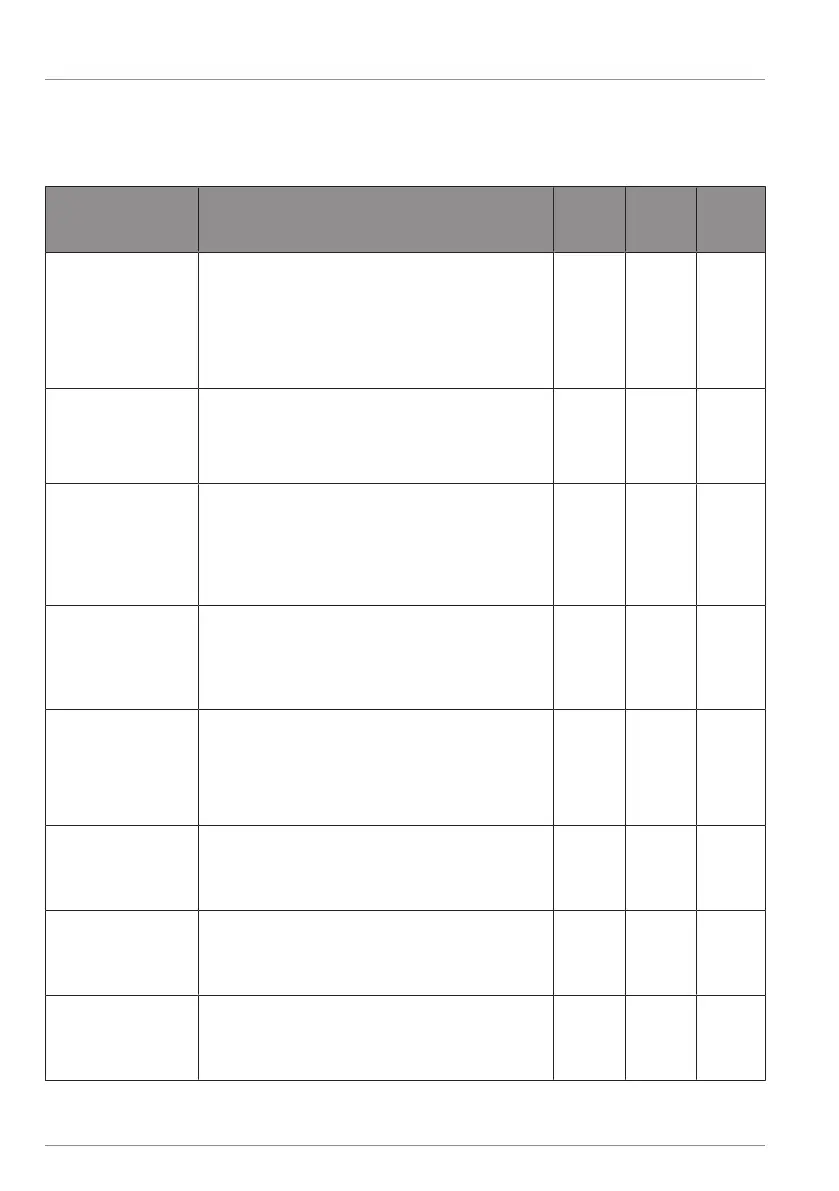

10.2.2 Maintenance intervals for the authorised specialist workshop

Assembly group Maintenance work Monthly Every

six

months

Yearly

Wheels and tyres

(see "10.2.4 Wheels

and tyres", pg.113)

► Check the tightening torques of the

wheel nuts. Additionally: For the first

time after 50 and 100km or after every

wheel change

► Check the tyres and the tyre inflation

pressure.

X

Axle and suspen-

sion (see "10.2.5

Axle and suspen-

sion", pg.114)

► Check the tightening torque of the fix-

ing bolts.

► Observe the maintenance instructions

from the axle manufacturer.

X

Brake system (see

"10.2.6 Brake sys-

tem", pg.114)

► Check the screw connections (addition-

ally: after the first trip).

► Check brake pad wear

► Check the brake discs/brake drums for

damage and cracks.

X

Compressed air

system (see "5.8

Draining the com-

pressed air tanks",

pg.35)

► Check the compressed air tank.

► Check the compressed air connec-

tions.

► Check the compressed air lines.

X

Lubrication points

(see "10.2.7 Lubric-

ating the trailer",

pg.115)

► Top up the grease on all the lubrication

points.

► Pay attention to the lubrication points

shown in the applicable operating in-

structions.

X

Electrical equip-

ment (see "10.2.8

Electrical equip-

ment", pg.115)

► Check all electrical components for

proper function.

X

Contour marking

(see "10.2.9 Con-

tour marking",

pg.115)

► Check the contour markings for com-

pleteness and legibility.

X

Bolted connections

(see "10.2.10 Bolted

connections",

pg.115)

► Perform a visual inspection for wear

and damage.

X

Loading...

Loading...