SHOP MANUAL

Paragraph 14 Cont.

4 3 2

Fig.

29—Open side of sector shaft

"U"

packing

(3)

should face Inward and open side of seal (4)

should face outward.

1.

Gear housing 3. "I!" packing

2.

Needle bearing 4. Seal

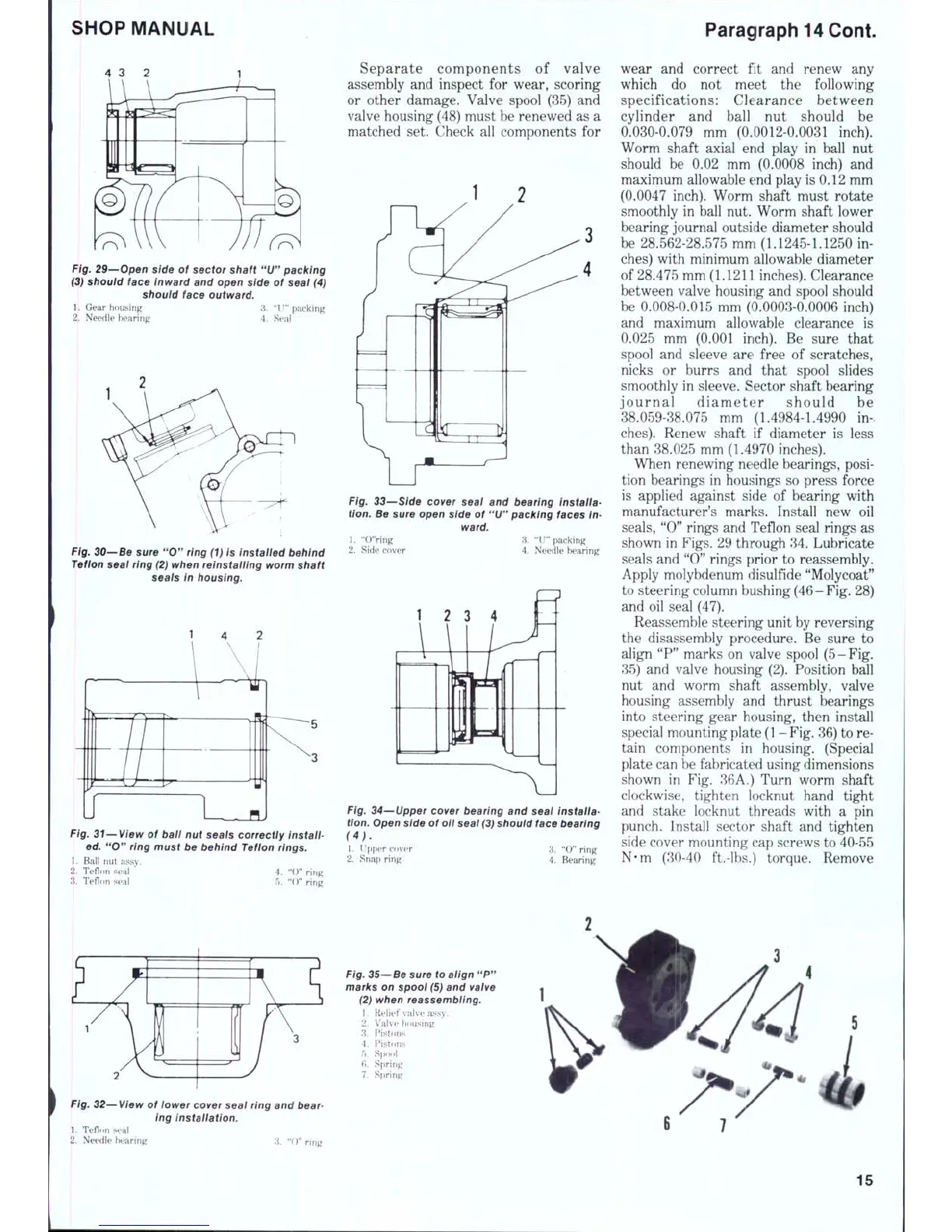

Fig.

30—Be sure

"O"

ring (1)

is installed behind

Teflon

seai

ring (2)

when reinstailing worm shaft

seals in housing.

Fig. 31—View of baii nut seais correctly instail-

ed.

"O"

ring must be behind Tefion rings.

1.

Ball nut assy.

2.

Teflon seal ' 4. "0" ring

3.

Teflon seal 5. "()" ring

Separate components of valve

assembly and inspect for wear, scoring

or other damage. Valve spool (35) and

valve housing (48) must be renewed as a

matched set. Check all components for

Fig. 33—Side cover seai and bearing Installa-

tion.

Be sure open side of

"U"

packing faces

in-

ward.

3.

"IJ" packing

4.

Needle bearing

1.

"O'Ving

2.

Side cover

1

2

3

4

ifi

1!

J

Fig. 34—Upper cover bearing and seal installa-

tion.

Open side of oii seai

(3)

shouid face bearing

(4).

1.

nppor cover 3. "O" ring

2.

Snap ring 4. Bearing

wear and correct fit and renew any

which do not meet the following

specifications: Clearance between

cylinder and ball nut should be

0.030-0.079 mm (0.0012-0.0031 inch).

Worm shaft axial end play in ball nut

should be 0.02 mm (0.0008 inch) and

maximum allowable end play is 0.12 mm

(0.0047 inch). Worm shaft must rotate

smoothly in ball nut. Worm shaft lower

bearing journal outside diameter should

be 28.562-28.575 mm (1.1245-1.1250 in-

ches) with minimum allowable diameter

of 28.475 mm (1.1211 inches). Clearance

between valve housing and spool should

be 0.008-0.015 mm (0.0003-0.0006 inch)

and maximum allowable clearance is

0.025 mm (0.001 inch). Be sure that

spool and sleeve are free of scratches,

nicks or burrs and that spool slides

smoothly in sleeve. Sector shaft bearing

journal diameter should be

38.059-38.075 mm (1.4984-1.4990 in-

ches).

Renew shaft if diameter is less

than 38.025 mm (1.4970 inches).

When renewing needle bearings, posi-

tion bearings in housings so press force

is applied against side of bearing with

manufacturer's marks. Install new oil

seals,

"0" rings and Teflon seal rings as

shown in Figs. 29 through 34. Lubricate

seals and "0" rings prior to reassembly.

Apply molybdenum disulfide "Molycoat"

to steering column bushing(46-Fig. 28)

and oil seal (47).

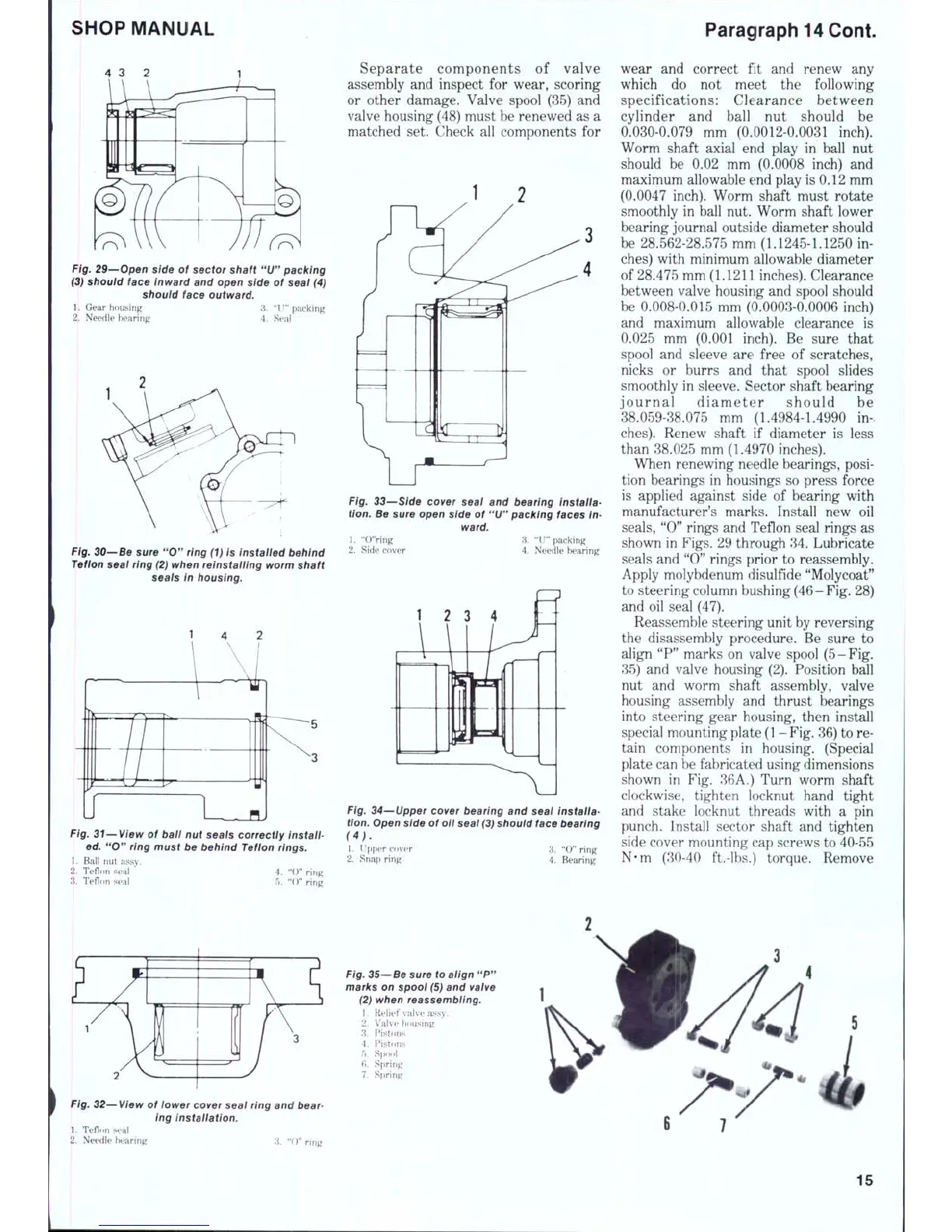

Reassemble steering unit by reversing

the disassembly procedure. Be sure to

align "P" marks on valve spool (5-Fig.

35) and valve housing (2). Position ball

nut and worm shaft assembly, valve

housing assembly and thrust bearings

into steering gear housing, then install

special mounting plate

(1

-

Fig.

36) to re-

tain components in housing. (Special

plate can be fabricated using dimensions

shown in Fig. 36A.) Turn worm shaft

clockwise, tighten locknut hand tight

and stake locknut threads with a pin

punch. Install sector shaft and tighten

side cover mounting cap screws to 40-55

N-m (30-40 ft.-lbs.) torque. Remove

Fig.

32—View of iower cover seai

ring

and bear-

ing installation.

1.

Teflnn sea!

2.

Needle bearing :i. "O" ring

Fig.

35—Be sure to aiign

"P"

marks on spool

(5)

and valve

(2) when reassembiing.

1.

Relief valve assy.

2.

Valve housing

3.

F^istons

4.

F^i.stons

5.

Spool

6. Spring

7.

Spring

6

7

15

Loading...

Loading...