Paragraphs 69-71

KUBOTA

12

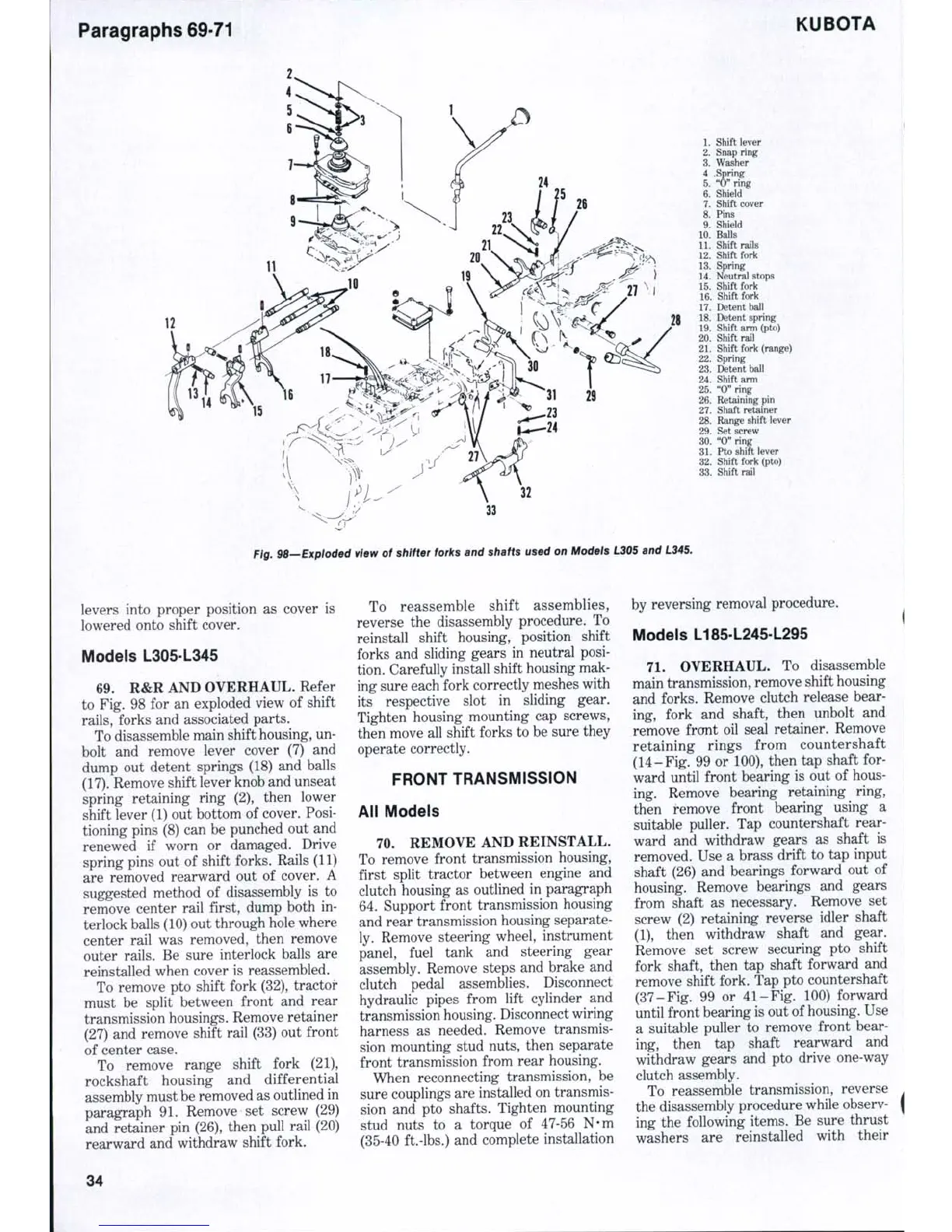

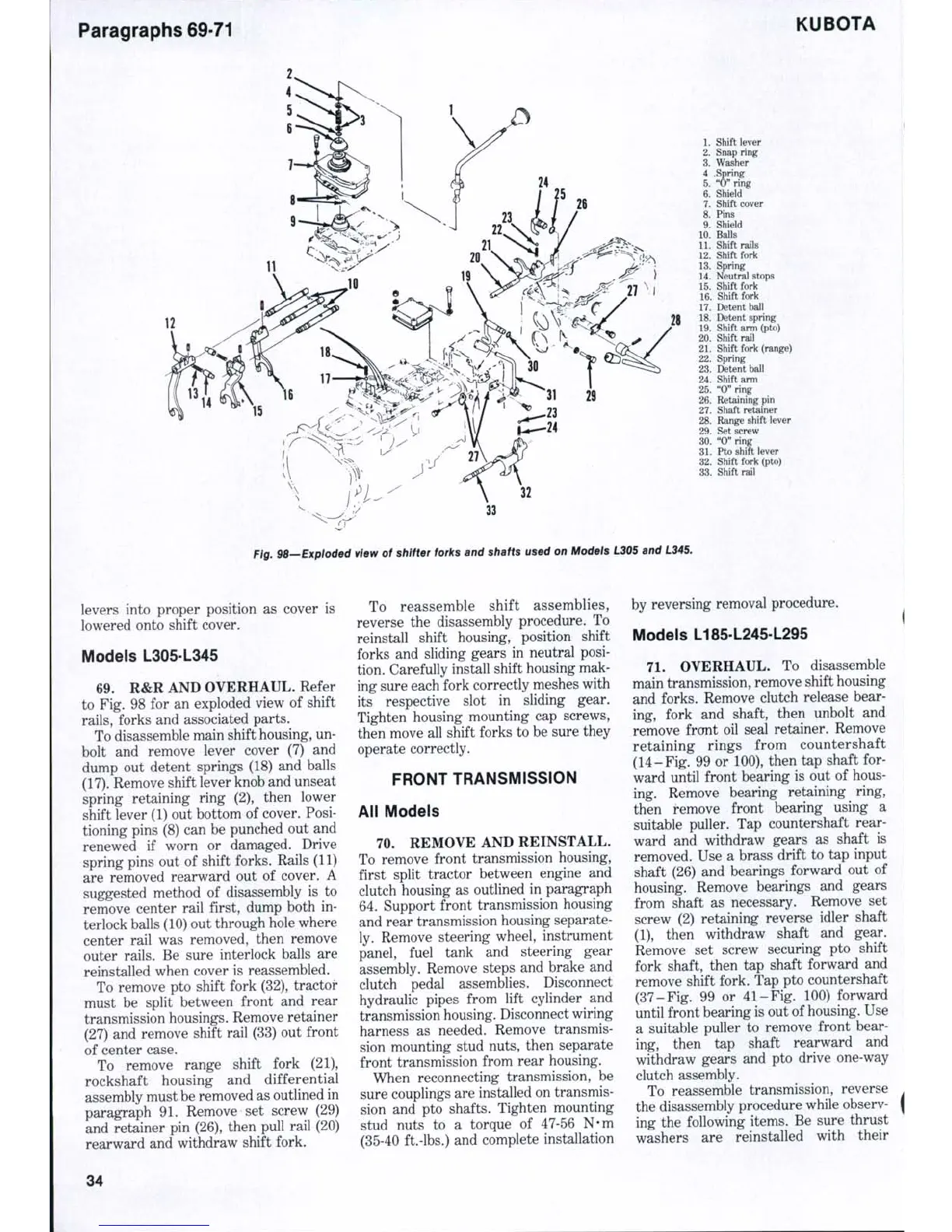

1.

Shift lever

2.

Snap ring

3.

Washer

4 .Spring

5.

"0" ring

6. Shield

7.

Shift cover

8. Pins

9. Shield

10.

Balls

11.

Shift rails

12.

Shift fork

13.

Spring

14.

Neutral stops

15.

Shift fork

16.

Shift fork

17.

Detent ball

18.

Detent spring

19.

Shift arm (pto)

20.

Shift rail

21.

Shift fork (range)

22.

Spring

23.

Detent ball

24.

Shift arm

25.

"0" ring

26.

Retaining pin

27.

Shaft retainer

28.

Range shift lever

29.

Set screw

30.

"0" ring

31.

Pto sbift lever

32.

Shift fork (pto)

33.

Shift rail

Fig. 98—Exploded view of shifter forks and shafts used on Models L305 and L345.

levers into proper position as cover is

lowered onto shift cover.

Models L305-L345

69.

R&R AND OVERHAUL. Refer

to Fig. 98 for an exploded view of shift

rails,

forks and associated parts.

To disassemble main shift housing, un-

bolt and remove lever cover (7) and

dump out detent springs (18) and balls

(17).

Remove shift lever knob and unseat

spring retaining ring (2), then lower

shift lever (1) out bottom of cover. Posi-

tioning pins (8) can be punched out and

renewed if worn or damaged. Drive

spring pins out of shift forks. Rails (11)

are removed rearward out of cover. A

suggested method of disassembly is to

remove center rail first, dump both in-

terlock balls (10) out through hole where

center rail was removed, then remove

outer rails. Be sure interlock balls are

reinstalled when cover is reassembled.

To remove pto shift fork (32), tractor-

must be split between front and rear

transmission housings. Remove retainer

(27) and remove shift rail (33) out front

of center case.

To remove range shift fork (21),

rockshaft housing and differential

assembly must be removed as outlined in

paragraph 91. Remove set screw (29)

and retainer pin (26), then pull rail (20)

rearward and withdraw shift fork.

To reassemble shift assemblies,

reverse the disassembly procedure. To

reinstall shift housing, position shift

forks and sliding gears in neutral posi-

tion. Carefully install shift housing mak-

ing sure each fork correctly meshes with

its respective slot in sliding gear.

Tighten housing mounting cap screws,

then move all shift forks to be sure they

operate correctly.

FRONT TRANSMISSION

All Models

70.

REMOVE AND REINSTALL.

To remove front transmission housing,

first split tractor between engine and

clutch housing as outlined in paragraph

64.

Support front transmission housing

and rear transmission housing separate-

ly. Remove steering wheel, instrument

panel, fuel tank and steering gear

assembly. Remove steps and brake and

clutch pedal assemblies. Disconnect

hydraulic pipes from lift cylinder and

transmission housing. Disconnect wiring

harness as needed. Remove transmis-

sion mounting stud nuts, then separate

front transmission from rear housing.

When reconnecting transmission, be

sure couplings are installed on transmis-

sion and pto shafts. Tighten mounting

stud nuts to a torque of 47-56 N-m

(35-40 ft.-lbs.) and complete installation

by reversing removal procedure.

Models L185-L245-L295

71.

OVERHAUL. To disassemble

main transmission, remove shift housing

and forks. Remove clutch release bear-

ing, fork and shaft, then unbolt and

remove frcmt oil seal retainer. Remove

retaining rings from countershaft

(14-Fig, 99 or 100), then tap shaft for-

ward until front bearing is out of hous-

ing. Remove bearing retaining ring,

then remove front bearing using a

suitable puller. Tap countershaft rear-

ward and withdraw gears as shaft is

removed. Use a brass drift to tap input

shaft (26) and bearings forward out of

housing. Remove bearings and gears

from shaft as necessary. Remove set

screw (2) retaining reverse idler shaft

(1),

then withdraw shaft and gear.

Remove set screw securing pto shift

fork shaft, then tap shaft forward and

remove shift fork. Tap pto countershaft

(37-Fig. 99 or 41-Fig. 100) forward

until front bearing is out of

housing.

Use

a suitable puller to remove front bear-

ing, then tap shaft rearward and

withdraw gears and pto drive one-way

clutch assembly.

To reassemble transmission, reverse

the disassembly procedure while observ-

ing the following items. Be sure thrust

washers are reinstalled with their

34

Loading...

Loading...