SHOP MANUAL

Paragraphs 1-3

FRONT SYSTEM

(TWO-WHEEL DRIVE)

FRONT AXLE

All Models So Equipped

1.

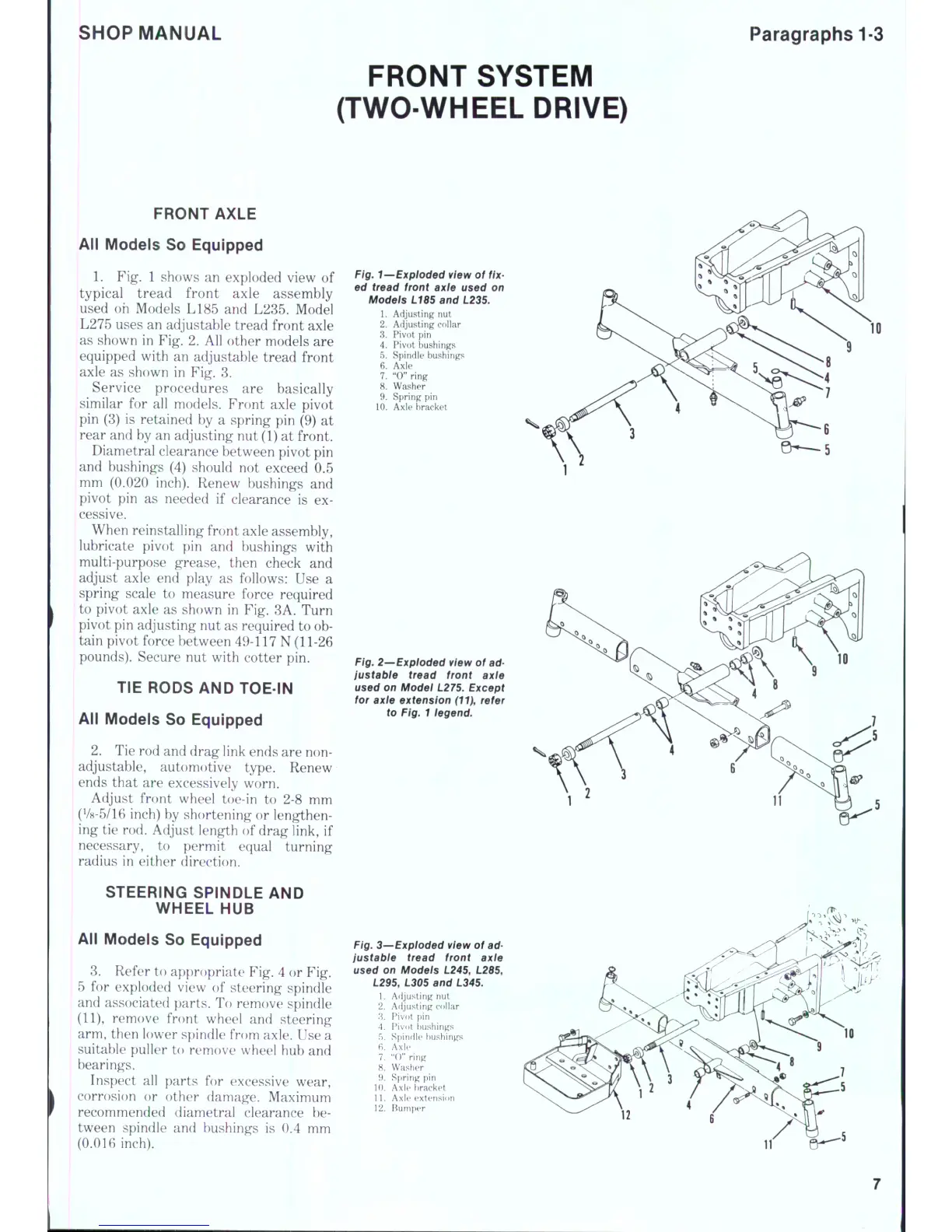

Fig. 1 shows an exploded view of

typical tread front axle assembly

used oh Models L185 and L285. Model

L275 uses an adjustable tread front axle

as shown in Fig. 2. All other models are

equipped with an adjustable tread front

axle as shown in Fig. 8.

Service procedures are basically

similar for all models. Front axle pivot

pin (8) is retained by a spring pin (9) at

rear and by an adjusting nut (1) at front.

Diametral clearance between pivot pin

and bushings (4) should not exceed 0.5

mm (0.020 inch). Renew bushings and

pivot pin as needed if clearance is ex-

cessive.

When reinstalling front axle assembly,

lubricate pivot pin and bushings with

multi-purpose grease, then check and

adjust axle end play as follows: Use a

spring scale to measure force required

to pivot axle as shown in Fig. 8A. Turn

pivot pin adjusting nut as required to ob-

tain pivot force between 49-117 N (11-26

pounds). Secure nut with cotter pin.

TIE RODS AND TOE-IN

All Models So Equipped

2.

Tie rod and drag link ends are non-

adjustabie, automotive type. Renew

ends that are excessively worn.

Adjust front wheel toe-in to 2-8 mm

(V8-5/16 inch) by shortening or lengthen-

ing tie rod. Adjust length of drag link, if

necessary, to permit equal turning

radius in either direction.

STEERING SPINDLE AND

WHEEL HUB

All Models So Equipped

8. Refer to appropriate Fig. 4 or Fig.

5 for exploded view of steering spindle

and associated parts. To remove spindle

(11),

remove front wheel and steering

arm, then lower spindle from axle. Use a

suitable puller to remove wheel hub and

bearings.

Inspect al! parts for excessive wear,

corrosion or other damage. Maximum

recommended diametral clearance be-

tween spindle and bushings is 0.4 mm

(0.016 inch).

Fig. 1—Expioded view of

fix-

ed tread front axle used on

Motfe/s L185 and L235.

1.

Adjusting nut

2.

Adjusting collar

3.

Pivot pin

4.

Pivot bushings

5.

Spindle bushings

6. Axle

7.

"0" ring

8. Washer

9. Spring pin

10.

Axle bracket

en—5

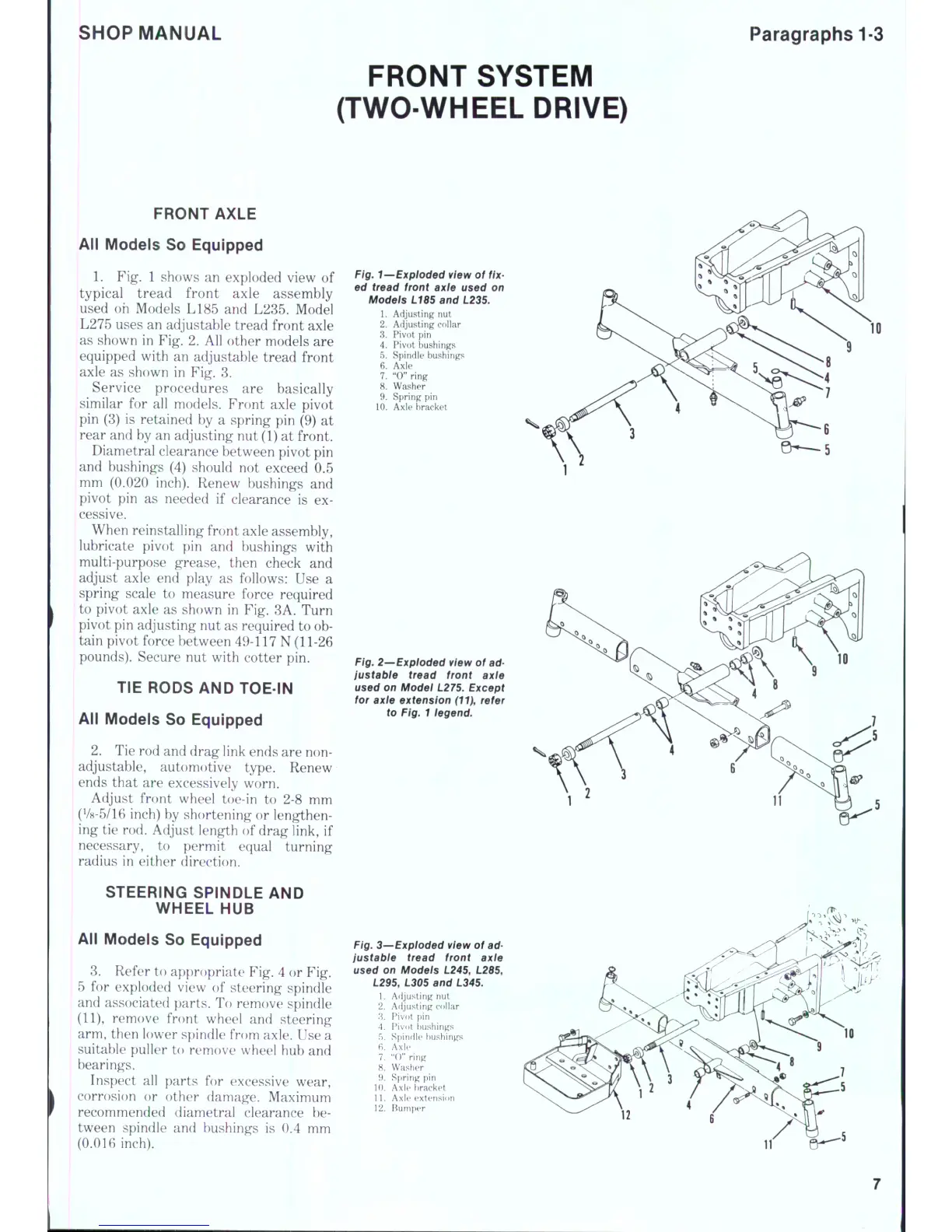

Fig.

2—Expioded view of ad-

justabie tread front axie

used on Modei

L275.

Except

for axle extension

(11),

refer

to Fig. 1 legend.

Fig.

3—Expioded view of ad-

justabie tread front axle

used on Modeis L245, L285,

L295, L305 and L345.

1.

Afljusting nut

2.

Adjusting collar

3.

Pivot i)in

4.

Pivot bushings

f).

Spindle bushings

fi. Axle

7.

"()" ring

8. Washer

9. Spring pin

10.

Axle bracket

11.

Axk* extension

12.

[^um[)er

Loading...

Loading...