Paragraph 7 Cont.

KUBOTA

34

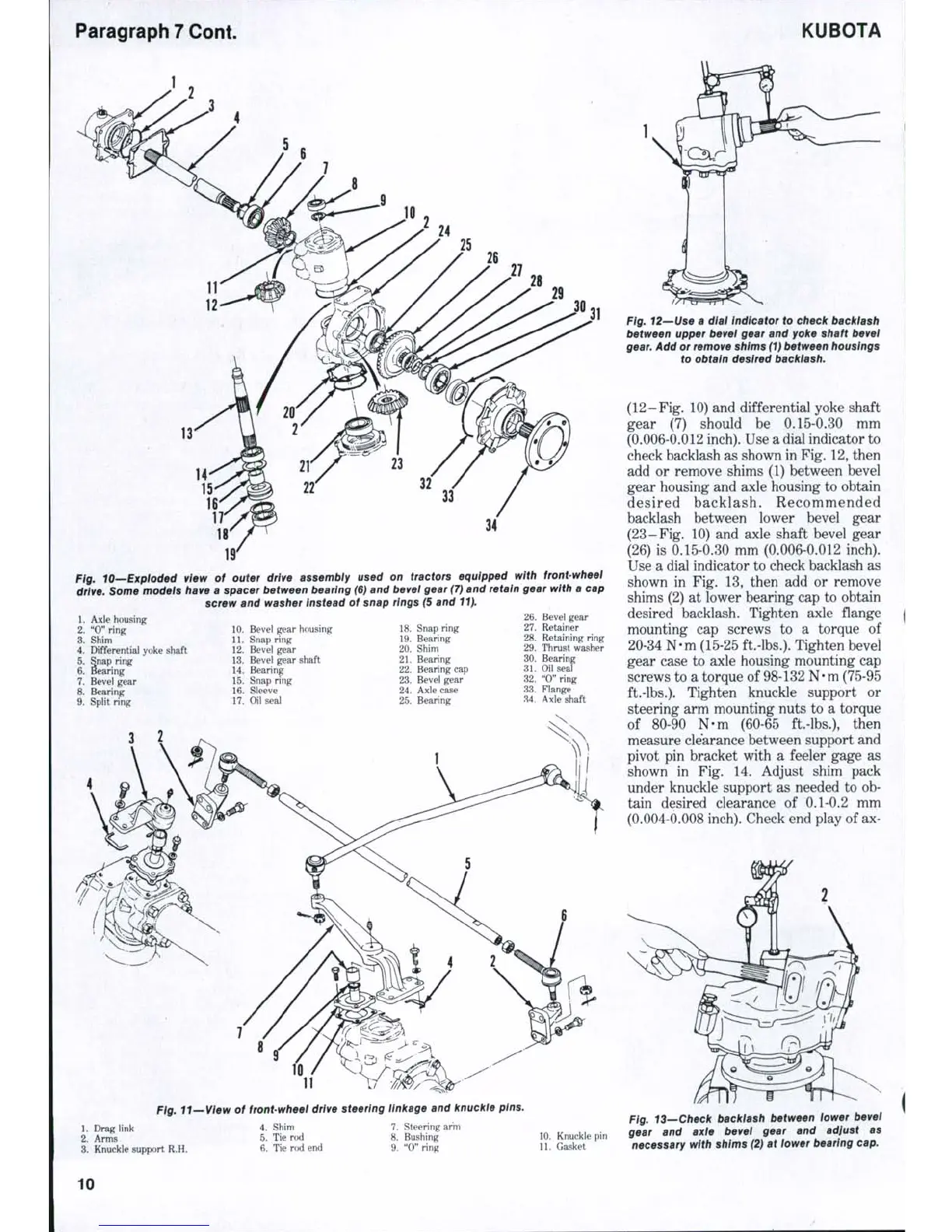

Fig. lO—Bxploded view of outer drive assembiy used on tractors equipped with front-wheel

drive. Some modeis have a spacer between bearing (6) and bevel gear (7) and retain gear with a cap

screw and washer Instead of snap rings (5 and 11).

1.

Axle housing

2.

"0" ring

3.

Shim

4.

Differential yoke shaft

5.

Snap ring

6. Bearing

7.

Bevel gear

8. Bearing

9. Split ring

10.

Bevel gear housing

11.

Snap ring

12.

Bevel gear

13.

Bevel gear shaft

14.

Bearing

15.

Snap ring

16.

Sleeve

17.

Oil seal

18.

Snap ring

19.

Bearing

20.

Shim

21.

Bearing

22.

Bearing cap

23.

Bevel gear

24.

Axle case

25.

Bearing

26.

27.

28.

29.

30.

31.

32.

33.

M.

Bevel gear

Retainer

Retaining ring

Thrust washer

Bearing

Oil seal

"0"

ring

Flange

Axle shaft

11

Pfg.

t t ~ W e i ¥ of front-wheel drive steering linkage and knuckle pins.

1.

Drag link

2.

Arms

3.

Knuckle support R.H.

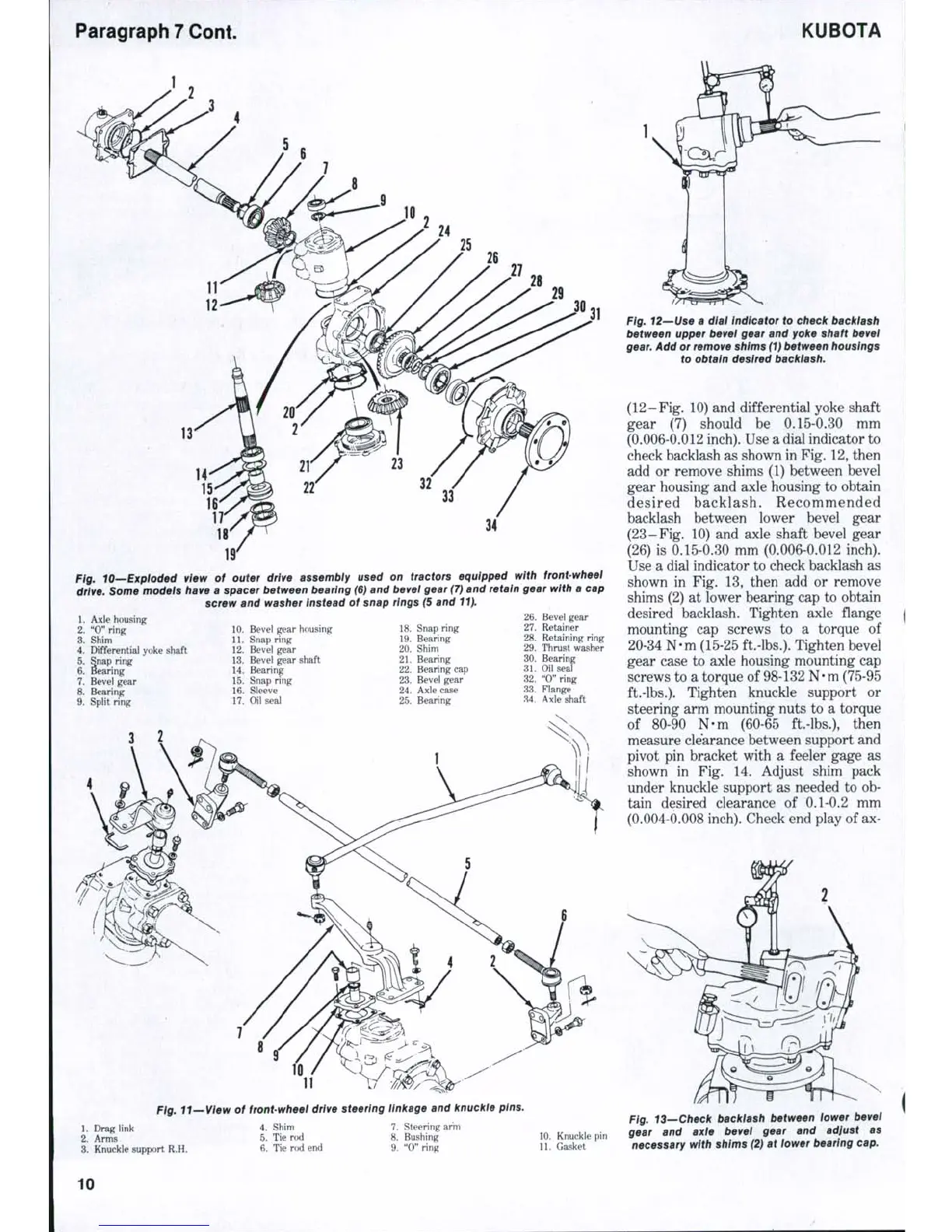

Fig. 12—Use a dial indicator to check backiash

between upper bevel gear and yoke shaft bevei

gear.

Add or remove shims (1) between housings

to obtain desired backlash.

(12-Fig. 10) and differential yoke shaft

gear (7) should be 0.15-0.30 mm

(0.006-0.012 inch). Use a dial indicator to

check backlash as shown in Fig. 12, then

add or remove shims (1) between bevel

gear housing and axle housing to obtain

desired backlash. Recommended

backlash between lower bevel gear

(23-Fig. 10) and axle shaft bevel gear

(26) is 0.15-0.30 mm (0.006-0.012 inch).

Use a dial indicator to check backlash as

shown in Fig. 13, then add or remove

shims (2) at lower bearing cap to obtain

desired backlash. Tighten axle flange

mounting cap screws to a torque of

20-34 N-m (15-25 ft.-lbs.). Tighten bevel

gear case to axle housing mounting cap

screws to a torque of 98-132 N-m (75-95

ft.-lbs.).

Tighten knuckle support or

steering arm mounting nuts to a torque

of 80-90 N-m (60-65 ft.-lbs.), then

measure clearance between support and

pivot pin bracket with a feeler gage as

shown in Fig. 14. Adjust shim pack

under knuckle support as needed to ob-

tain desired clearance of 0.1-0.2 mm

(0.004-0.008 inch). Check end play of ax-

4.

Shim

5.

Tie rod

6. Tie rod end

7.

Steering arm

8. Bushing

9. "0" ring

10.

Knuckle pin

11.

Gasket

Fig. 13—Check backlash between iower bevel

gear and axle bevei gear and adjust as

necessary with shims (2) at lower bearing cap.

10

Loading...

Loading...