SHOP MANUAL

allowable clearance is 0.10 mm (0.0039

inch).

Recommended finished inside

diameter of valve guides is 8.015-8.030

mm (0.3156-0.3161 inch).

VALVE SPRINGS

All Models

27.

Valve springs are inter-

changeable for intake and exhaust

valves. Approximate free length is 42

mm (1.65 inches) and minimum

allowable free length is 41.2 mm (1.62 in-

ches) on all models. Renew springs

which are distorted, heat discolored or

fail to meet following test specifications:

Springs should test 117.7 N (26.5

pounds) when compressed to a length of

35.15 mm (1.384 inches). Minimum test

specifications are 100 N (22.5 pounds) at

35.15 mm (1.384 inches).

VALVE LEVERS

All Models

28.

Intake and exhaust valve levers

(rocker arms) are interchangeable on all

models. However, it is recommended

that valve levers be reinstalled in their

original positions if not being renewed.

All valve levers are equipped with

renewable bushings (10-Fig. 48). When

installing new bushing, be sure hole in

bushing is aligned with corresponding

hole in valve lever. Recommended

operating clearance of shaft in valve

levers is 0.02-0.07 mm (0.0008-0.0028

inch) and allowable limit is 0.15 mm

(0.006 inch). Shaft diameter should be

13.973-13.984 mm (0.5501-0.5506 inch)

and bushing inside diameter should be

14.002-14.043 mm (0.5513-0.5529 inch).

Valve levers and shaft are lubricated

by oil metered to shaft support bracket

from rear camshaft bearing. When

assembling valve lever assembly, make

sure all oil passages are open and pro-

perly positioned.

CAM FOLLOWERS

All Models

29.

All models are equipped with bar-

rel type cam followers (tappets) which

can be removed from the top after

removing cylinder head. Cam followers

operate directly in unbushed crankcase

bores on all models.

Check for wear or other damage and

renew if necessary. Check camshaft at

same time and renew if cam lobe surface

is chipped, scored or excessively worn.

Refer to paragraph 33.

VALVE TIMING

All Models

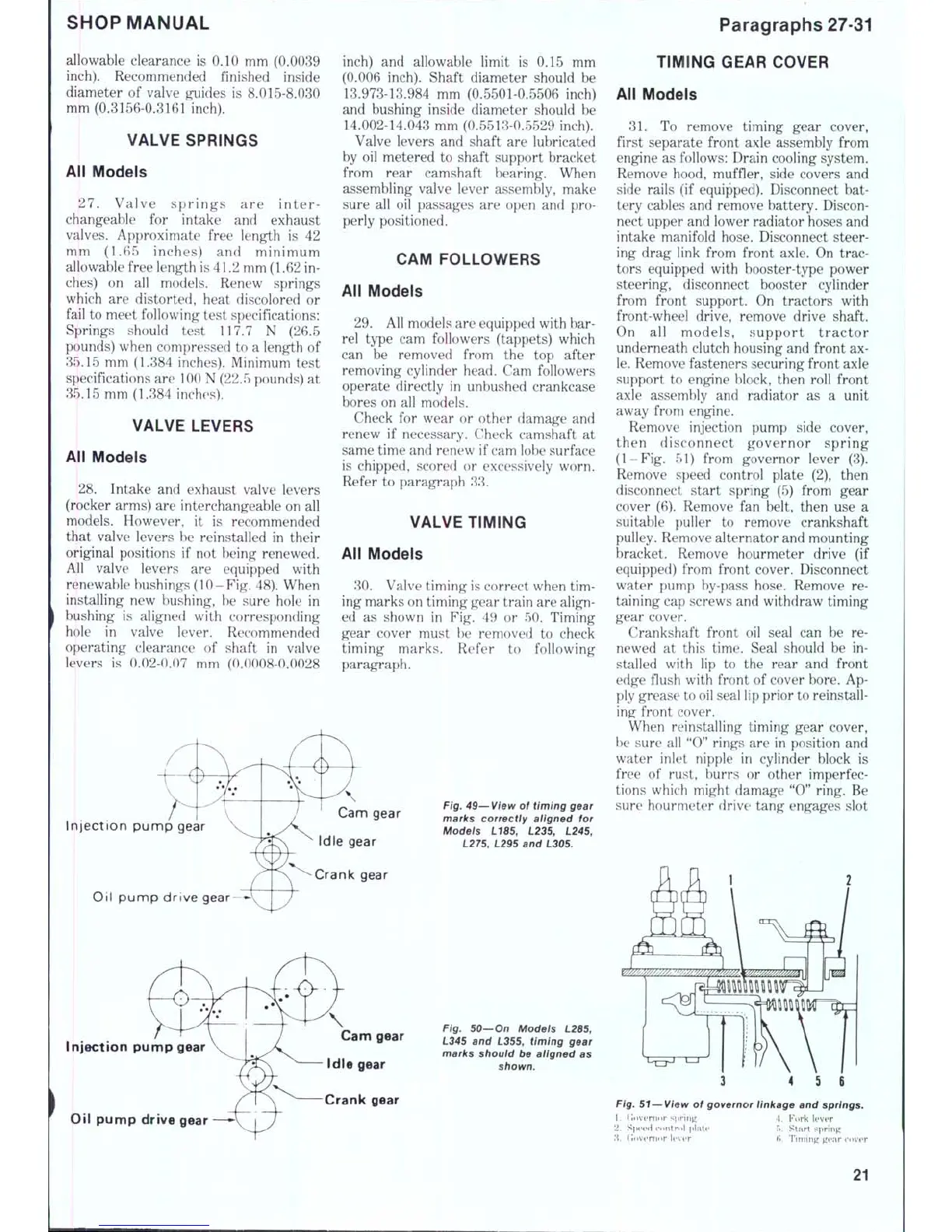

30.

Valve timing is correct when tim-

ing marks on timing gear train are align-

ed as shown in Fig. 49 or 50. Timing

gear cover must he removed to check

timing marks. Refer to following

paragraph.

Injection punnp gear

Oil punnp drive gear

Idle gear

Crank gear

Fig. 49—View of timing gear

marks correctly aligned for

Modeis L185, 1235, L245,

L275, L295 and L305.

Injection pump gear

Oil pump drive gear

Cam gear

Idle gear

Crank gear

Fig. 50—On Modeis L285,

L345 and L355, timing gear

marks shouid be aiigned as

shown.

Paragraphs 27-31

TIMING GEAR COVER

All Models

31.

To remove timing gear cover,

first separate front axle assembly from

engine as follows: Drain cooling system.

Remove hood, muffler, side covers and

side rails (if equipped). Disconnect bat-

tery cables and remove battery. Discon-

nect upper and lower radiator hoses and

intake manifold hose. Disconnect steer-

ing drag link from front axle. On trac-

tors equipped with booster-type power

steering, disconnect booster cylinder

from front support. On tractors with

front-wheel drive, remove drive shaft.

On all models, support tractor

underneath clutch housing and front ax-

le.

Remove fasteners securing front axle

support to engine block, then roll front

axle assembly and radiator as a unit

away from engine.

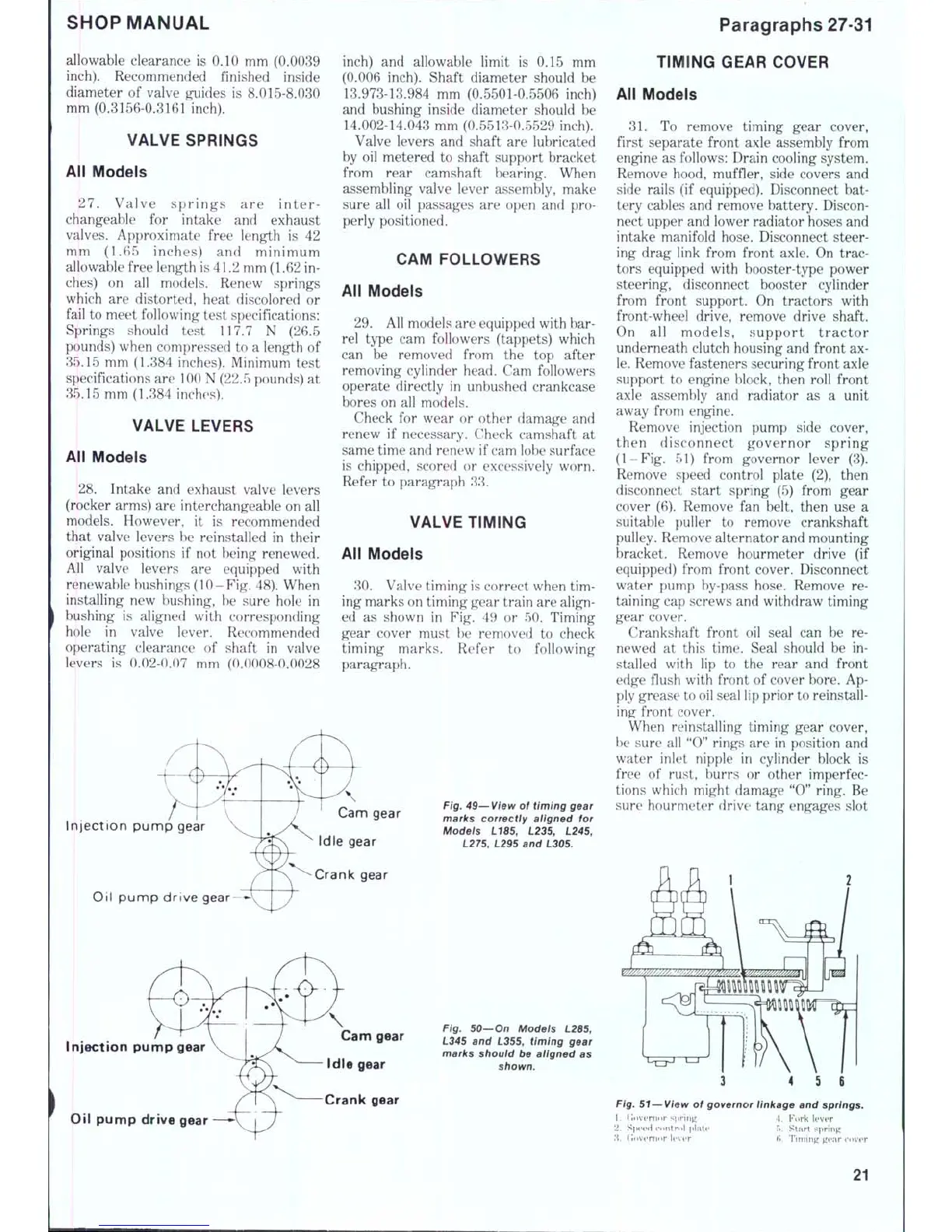

Remove injection pump side cover,

then disconnect governor spring

(1-Fig. 51) from governor lever (3).

Remove speed control plate (2), then

disconnect start spring (5) from gear

cover (6). Remove fan belt, then use a

suitable puller to remove crankshaft

pulley. Remove alternator and mounting

bracket. Remove hourmeter drive (if

equipped) from front cover. Disconnect

water pump by-pass hose. Remove re-

taining cap screws and withdraw timing

gear cover.

Crankshaft front oil seal can be re-

newed at this time. Seal should be in-

stalled with lip to the rear and front

edge fiush with front of cover bore. Ap-

ply grease to oil seal lip prior to reinstall-

ing^ front cover.

When reinstalling timing gear cover,

be sure all "0" rings are in position and

water inlet nipple in cylinder block is

free of rust, burrs or other imperfec-

tions which might damage "0" ring. Be

sure hourmeter drive tang engages slot

^

"V^.

//j////////./yy//////////Z<W//C^i^yy^y/7/A^A

Mm

3

4 5 6

Fig. 51—View of governor linkage and springs.

1.

(lovernor sp

\. Fork Ifver

f).

Start spring

(i.

Timing gear cover

21

Loading...

Loading...