SHOP MANUAL

Paragraph

7

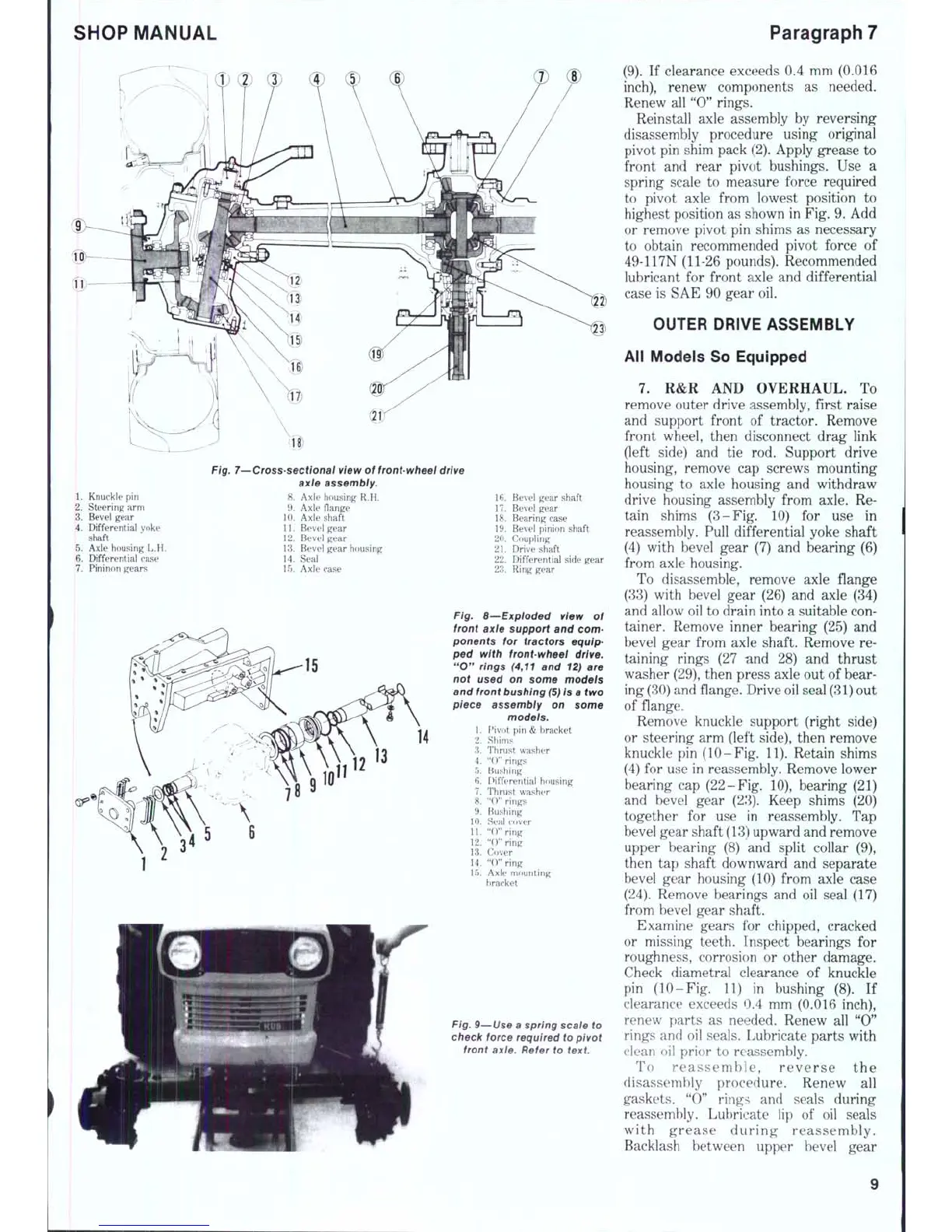

Fig. 7—Cross-sectional view

of

front-wheel

drive

axie assembly.

1. Knuckle

pin 8.

Axle housing

R.H.

2.

Steering arm 9. Axle flange

3.

Bevel gear 10. Axle shaft

4.

Differential yoke 11. Bevel gear

shaft ' 12. Bevel gear

5.

Axle housing L.H. 13. Bevel gear housing

6. Differential ease 14. Seal

7.

Pininon gears 15. Axle case

16.

Bevel gear shaft

17.

Bevel gear

18.

Bearing case

19.

Bevel pinion shaft

20.

Coupling

21.

Drive shaft

22.

Differential side gear

23.

Ring gear

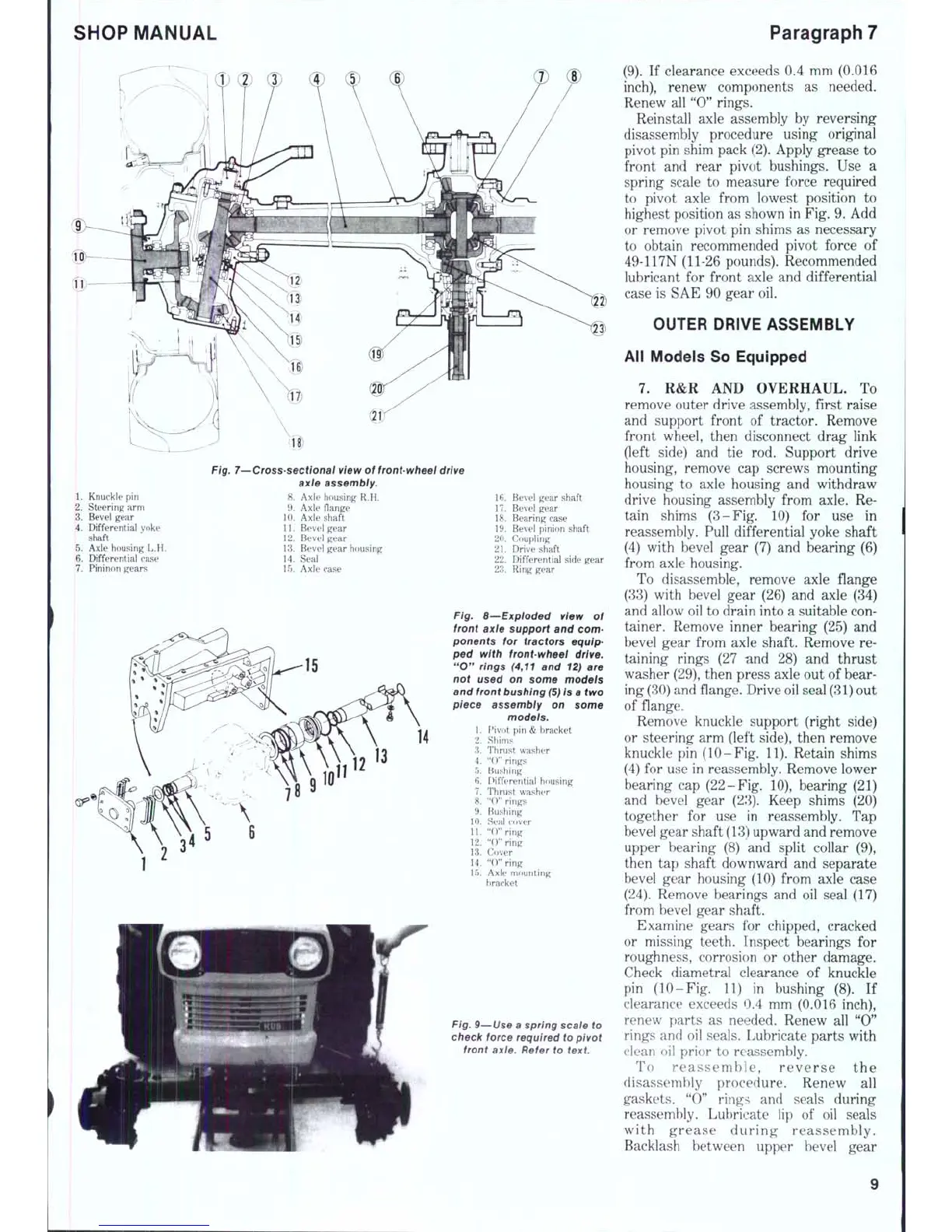

Fig. 8—Expioded view

of

front axte support

and

com-

ponents

for

tractors equip-

ped with front-wheel drive.

"0" rings (4,11

and

12)

are

not used

on

some models

and

front

bushing

(5)

is a two

piece assembly

on

some

models.

1.

Pivot pin & bracket

2.

Shims

3.

Thrust washer

4.

"()" rings

5.

Bushing

6. Differential housing

7.

Thrust washer

8. "(T' rings

9. Bushing

10.

Seal cover

11.

"0" ring

12.

"O"ring

13.

Cover

14.

"0" ring

15.

Axle mounting

bracket

Fig.

9—Use

a

spring scale

to

check force required

to

pivot

front axle. Refer

to

text

(9).

If

clearance exceeds

0.4 mm

(0.016

inch),

renew components

as

needed.

Renew

all

"0" rings.

Reinstall axle assembly

by

reversing

disassembly procedure using original

pivot

pin

shim pack (2). Apply grease

to

front

and

rear pivot bushings.

Use a

spring scale

to

measure force required

to pivot axle from lowest position

to

highest position

as

shown

in

Fig.

9.

Add

or remove pivot

pin

shims

as

necessary

to obtain recommended pivot force

of

49-117N (11-26 pounds). Recommended

lubricant

for

front axle

and

differential

case

is

SAE

90

gear

oil.

OUTER DRIVE ASSEMBLY

All Models

So

Equipped

7.

R&R AND

OVERHAUL,

To

remove outer drive assembly, first raise

and support front

of

tractor. Remove

front wheel, then disconnect drag link

(left side)

and tie rod.

Support drive

housing, remove

cap

screws mounting

housing

to

axle housing

and

withdraw

drive housing assembly from axle.

Re-

tain shims (3-Fig.

10) for use in

reassembly. Pull differential yoke shaft

(4) with bevel gear

(7) and

bearing

(6)

from axle housing.

To disassemble, remove axle flange

(33) with bevel gear

(26) and

axle

(34)

and allow

oil

to

drain into

a

suitable

con-

tainer. Remove inner bearing

(25) and

bevel gear from axle shaft. Remove

re-

taining rings

(27 nnd 28) and

thrust

washer (29), then press axle

out

of

bear-

ing

(30)

and

flange. Drive oil seal

(31)

out

of flange.

Remove knuckle support (right side)

or steering

arm

(left side), then remove

knuckle

pin

(10-Fig.

11).

Retain shims

(4)

for

use

in

reassembly. Remove lower

bearing

cap

(22-Fig.

10),

bearing

(21)

and bevel gear

(23).

Keep shims

(20)

together

for use In

reassembly.

T'ap

bevel gear shaft

(13)

upward

and

remove

upper bearing

(8) and

split collar

(9),

then

tap

shaft downward

and

separate

bevel gear housing

(10)

from axle case

(24).

Remove bearings

and oil

seal

(17)

from bevel gear shaft.

Examine gears

for

chipped, cracked

or missing teeth. Inspect bearings

for

roughness, corrosion

or

other damage.

Check diametral clearance

of

knuckle

pin (10-Fig.

11) in

bushing

(8). If

clearance exceeds

0.4 mm

(0.016 inch),

renew parts

as

needed. Renew

all "0"

rings

and oil

seals. Lubricate parts with

clean

oil

prior

to

reassembly.

To reassemb le, revers e

the

disassembly procedure. Renew

all

gaskets.

"0"

rings

and

seals during

reassembly. Lubricate

lip of oil

seals

with grease during reassembly.

Backlash between upper bevel gear

Loading...

Loading...