Paragraphs 48-52

nuts,

align control rack

pin

with slot

in

crankcase

(Fig. 60) and

lift pump

assembly from crankcase. Do not lose or

damage shim pack located between

pump fiange

and

crankcase. Shims con-

trol pump timing

and

same number

of

shims must be reinstalled unless timing

is

to be

changed.

When reinstalling pump,

be

sure

to

guide rack control

pin

into notch

in

governor

arm and

crankcase.

Use

removed shim pack unless timing is to be

changed. Bleed

air

from system

as

previously outlined.

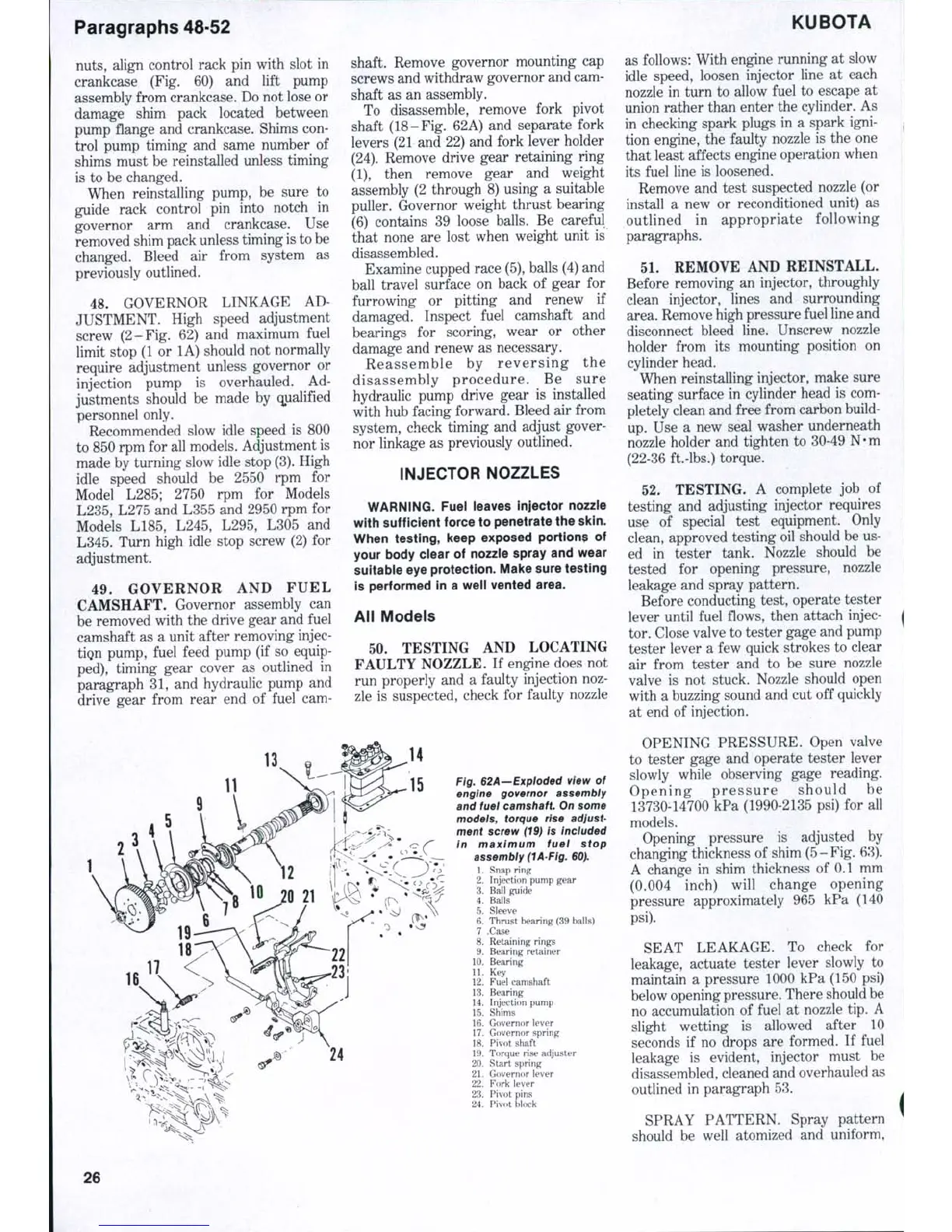

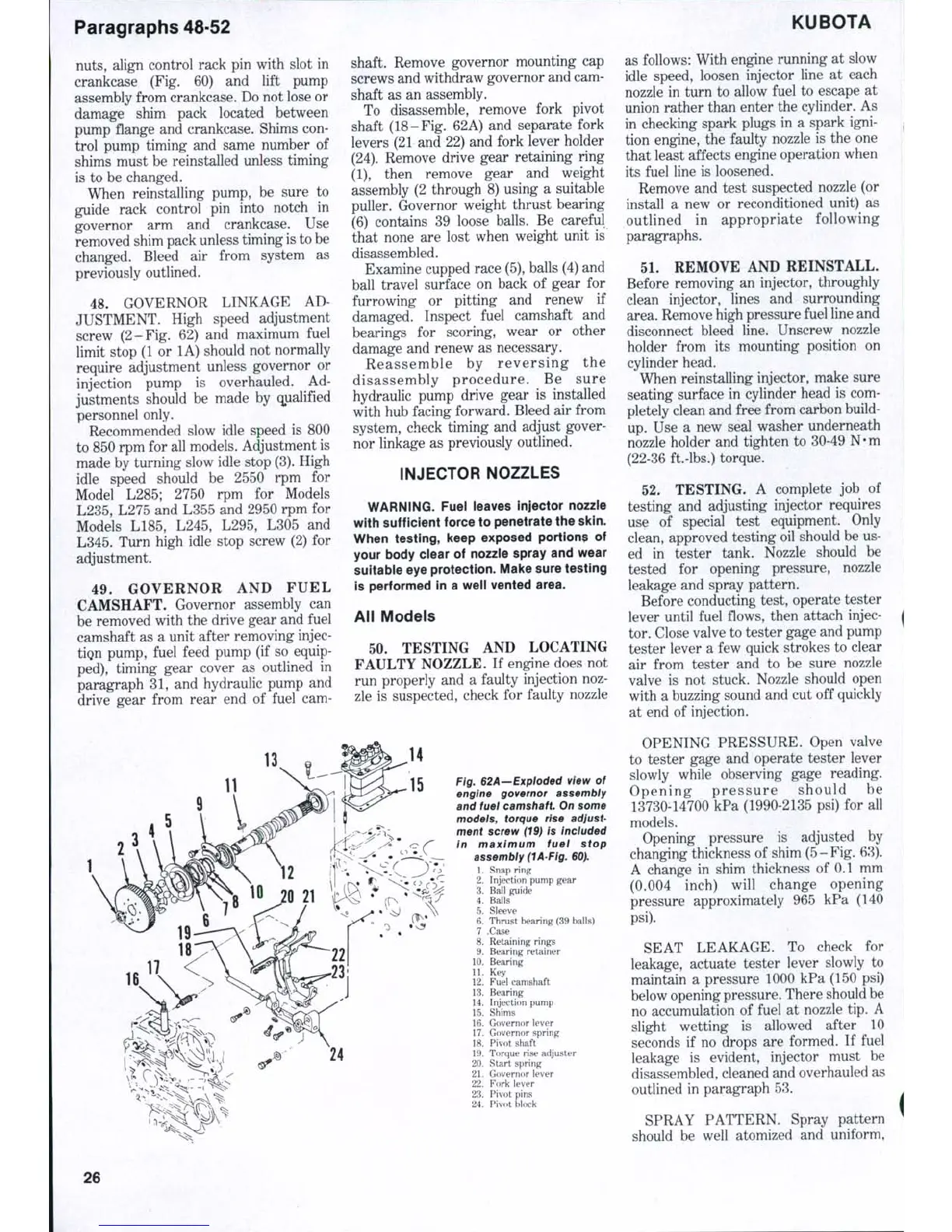

48.

GOVERNOR LINKAGE

AD-

JUSTMENT. High speed adjustment

screw (2-Fig.

62) and

maximum fuel

limit stop (1

or

lA) should not normally

require adjustment unless governor

or

injection pump

is

overhauled.

Ad-

justments should

be

made

by

qualified

personnel only.

Recommended slow idle speed

is 800

to 850 rpm

for

all models. Adjustment is

made by turning slow idle stop (3). High

idle speed should

be

2550

rpm for

Model L285; 2750

rpm for

Models

L235,

L275 and L355 and 2950 rpm

for

Models

L185,

L245, L295, L305

and

L345.

Turn high idle stop screw (2)

for

adjustment.

49.

GOVERNOR

AND

FUEL

CAMSHAFT. Governor assembly

can

be removed with the drive gear and fuel

camshaft as

a

unit after removing injec-

tion pump, fuel feed pump

(if so

equip-

ped),

timing gear cover

as

outlined

in

paragraph 31,

and

hydraulic pump

and

drive gear from rear

end of

fuel

cam-

13

shaft. Remove governor mounting

cap

screws and withdraw governor and cam-

shaft

as an

assembly.

To disassemble, remove fork pivot

shaft (18-Fig. 62A)

and

separate fork

levers (21

and

22) and fork lever holder

(24).

Remove drive gear retaining ring

(1),

then remove gear

and

weight

assembly

(2

through

8)

using

a

suitable

puller. (Governor weight thrust bearing

(6) contains

39

loose balls.

Be

careful

that none

are

lost when weight unit

is

disassembled.

Examine cupped race (5), balls (4) and

ball travel surface

on

back

of

gear

for

furrowing

or

pitting

and

renew

if

damaged. Inspect fuel camshaft

and

bearings

for

scoring, wear

or

other

damage and renew

as

necessary.

Reassemble

by

reversing

the

disassembly procedure.

Be

sure

hydraulic pump drive gear

is

installed

with hub facing forward. Bleed

air

from

system, check timing and adjust gover-

nor linkage

as

previously outlined.

INJECTOR NOZZLES

WARNING. Fuel leaves injector nozzle

with sufficient force to penetrate the

skin.

When testing, keep exposed portions of

your body clear of nozzle spray and wear

suitable eye protection. Make sure testing

is performed in a well vented area.

All Models

50.

TESTING

AND

LOCATING

FAULTY NOZZLE.

If

engine does

not

run properly

and a

faulty injection noz-

zle

is

suspected, check

for

faulty nozzle

Fig. 62A—Expioded view

of

engine governor assembly

and fuel camshaft. On some

models, torque rise adjust-

ment screw (19)

is

included

In maximum fuel stop

assembly (lA-Flg. 60),

1.

Snap ring

2.

Injection pump gear

3.

Ball guide

4.

Baits

5. Sleeve

6. Thrust bearing (39 balls)

7 .Case

8. Retaining rings

9. Bearing retainer

10.

Bearing

11.

Key

12.

Fuel camshaft

13.

Bearing

14.

Injection pump

15.

Shims

16.

Governor lever

17.

Governor spring

18.

Pivot shaft

19.

Torque rise adjuster

20.

Start spring

21.

Governor lever

22.

Fork !ever

23.

Pivot pins

24.

Pivot block

KUBOTA

as follows: With engine running

at

slow

idle speed, loosen injector line

at

each

nozzle

in

turn

to

allow fuel

to

escape

at

union rather than enter the cylinder.

As

in checking spark plugs

in a

spark igni-

tion engine,

the

faulty nozzle

is the one

that least affects engine operation when

its fuel line

is

loosened.

Remove

and

test suspected nozzle (or

install

a new or

reconditioned unit)

as

outlined

in

appropriate following

paragraphs.

51.

REMOVE AND REINSTALL.

Before removing

an

injector, throughly

clean injector, lines

and

surrounding

area. Remove high pressure fuel line and

disconnect bleed line. Unscrew nozzle

holder from

its

mounting position

on

cylinder head.

When reinstalling injector, make sure

seating surface

in

cylinder head

is

com-

pletely clean and free from carbon build-

up.

Use a new

seal washer underneath

nozzle holder

and

tighten

to

30-49 N*m

(22-36 ft.-lbs.) torque.

52.

TESTING.

A

complete

job of

testing

and

adjusting injector requires

use

of

special test equipment. Only

clean, approved testing oil should be us-

ed

in

tester tank. Nozzle should

be

tested

for

opening pressure, nozzle

leakage

and

spray pattern.

Before conducting test, operate tester

lever until fuel fiows, then attach injec-

tor. Close valve to tester gage and pump

tester lever

a

few quick strokes

to

clear

air from tester

and to be

sure nozzle

valve

is not

stuck. Nozzle should open

with

a

buzzing sound and cut

off

quickly

at end

of

injection.

OPENING PRESSURE. Open valve

to tester gage

and

operate tester lever

slowly while observing gage reading.

Opening pr es su re should

be

13730-14700 kPa (1990-2135 psi)

for all

models.

Opening pressure

is

adjusted

by

changing thickness

of

shim (5-Fig. 63).

A change

in

shim thickness

of

0.1

mm

(0.004 inch) will change opening

pressure approximately

965 kPa (140

psi).

SEAT LEAKAGE.

To

check

for

leakage, actuate tester lever slowly

to

maintain

a

pressure 1000

kPa

(150

psi)

below opening pressure. There should be

no accumulation

of

fuel

at

nozzle tip.

A

slight wetting

is

allowed after

10

seconds

if no

drops

are

formed.

If

fuel

leakage

is

evident, injector must

be

disassembled, cleaned and overhauled

as

outlined

in

paragraph 53.

SPRAY PATTERN. Spray pattern

should

be

well atomized

and

uniform.

26

Loading...

Loading...