HEAT PUMP

Page 16

505023M 08/11

HEAT PUMP

Installing Heat Pump and accessories

Equipment Installation

Follow all equipment installation instructions provided with

each unit.

Pressure Switch

A pressure switch (HFC−22 [27W12]; HFC−410A [27W13])

is required for applications with a Lennox heat pump (Op-

tions 2 and 3). This switch acts as a guard in case of high

head pressures during 1st− and 2nd−stage heating. The

switch’s cut out and cut in points are shown in table 7.

Table 7. Cut−out and Cut−in (Reset) Points

Refrigerant Cut−Out Cut−in (Reset)

HCFC−22 375 psig (2551 kPa) 275 psig (1862 kPa)

HFC−410A 550 psig (3965 kPa) 425 psig (3102 kPa)

NOTE − If a pressure switch is factory installed in the unit,

do not remove the switch or switch wires.

The switch may also be fastened directly to the vapor valve

service port which becomes the discharge line in heat

pump heating mode (see figure 12).

Pressure Switch Wiring

Pull a two−wire thermostat cable from the field-installed

pressure switch to the zone control panel and connect at

the pressure switch, and at the zone control panel as

shown in the connection location diagram (see figure 15).

Tee (High Pressure Switch; Heat Pumps only)

A tee (Lennox #87071) is needed to install the pressure

switch along with a valve core (Schrader) for checking

pressure in the vapor line during heat pump heating mode

(see figure 12).

The switch may also be fastened directly to the vapor valve

service port which becomes the discharge line in heat

pump mode.

TO

REVERSING

VALVE

VAPOR LINE

(TO INDOOR

COIL)

HIGH PRESSURE

SWITCH

NEW SERVICE

PORT

CAUTION − High Pressure Switch must be installed on open side

of tee first to prevent refrigerant loss.

VALVE DEPRES-

SOR TEE (LENNOX

87071)

Figure 12. Tee & Vapor Line High Pressure

Switch

Balance Point Sensor (Outdoor Thermostat)

A balance point sensor (kit 56A87, figure 13) may be imple-

mented in a dual-fuel (Option 3) system. This thermostat

monitors the outdoor temperature, compares it to the bal-

ance point setting, and signals the zone control if the read-

ing is below the set point. The zone control then instructs

the gas furnace to provide all the heating and prohibits the

heat pump from attempting to fill a demand for heat.

Figure 13. Balance Point Sensor (56A87)

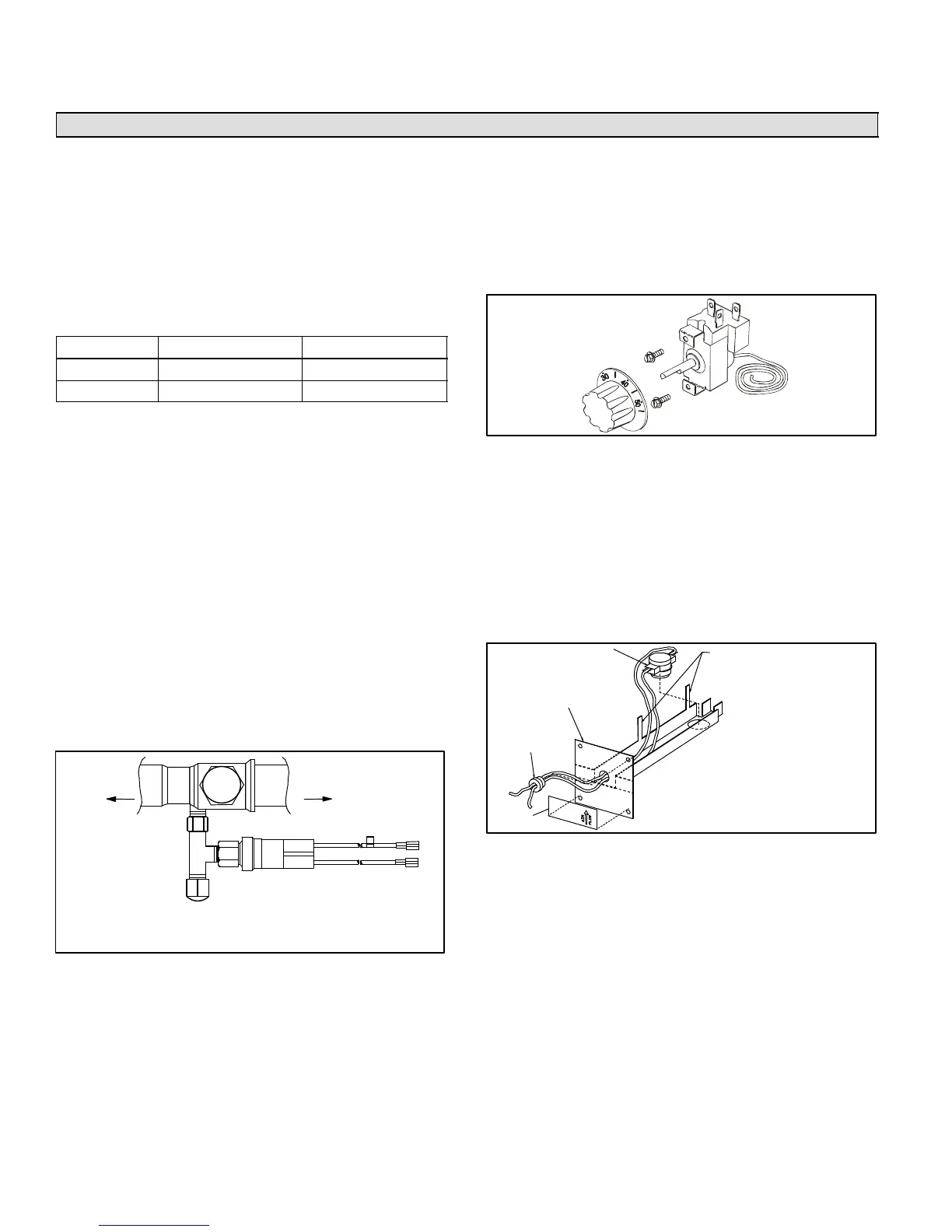

Defrost Tempering Kit

A defrost tempering kit (67M41) may be implemented in a

dual-fuel (Option 3) system. This kit consists of a thermo-

stat probe/switch which is installed between the furnace

and the evaporator coil to turn the furnace on (at 80F) and

off (at 90F) during a defrost cycle. This tempers the dis-

charge air and protects the compressor from high refrig-

eration pressures during defrost. Figure 14 shows the kit;

see figure 3 (Page 6) for location of the probe.

LIMIT CONTROL

MOUNTING

BRACKET

STRAIN

RELIEF

LABEL

WHEN FULLY ASSEMBLED,

TABS ARE BENT DOWN TO

HOLD CONTROL AND WIRES

IN PLACE.

Figure 14. Defrost Tempering Limit Control

Loading...

Loading...