GENERAL

Page 9

HARMONY IIIT ZONE CONTROL SYSTEM

Zone Control Panel Jumpers (Determining PIAB Jumper Settings)

Determining PIAB Jumper Settings

NOTE − Use the PIAB Calculation Worksheet on Page 60

(also see example below) to help calculate the zone con-

trol system PIAB settings.

1. From a cooling load analysis, determine what CFM is

required for each zone. Also, from the air handler, de-

termine its minimum and maximum CFM ratings.

2. Using the PIAB formula, found in Table 5 and re-

flected in the worksheet below, calculate the Percent

Into Adjustment Band (PIAB) using the values from

step 1 for each zone. Table 5 also gives example CFM

values to illustrates how to determine the correct

jumper for the PIAB for Zone 1 using those values.

3. Set the air selection jumper for the zone using the per-

cent air determined in step 2. If the percent air falls be-

tween available jumper settings, select the nearest

unit of ten.

4. For each zone, repeat steps 1 through 3.

Note − See page 8 for information on 140F DAS (dis-

charge air sensor) jumper used on Zone 1 PIAB.

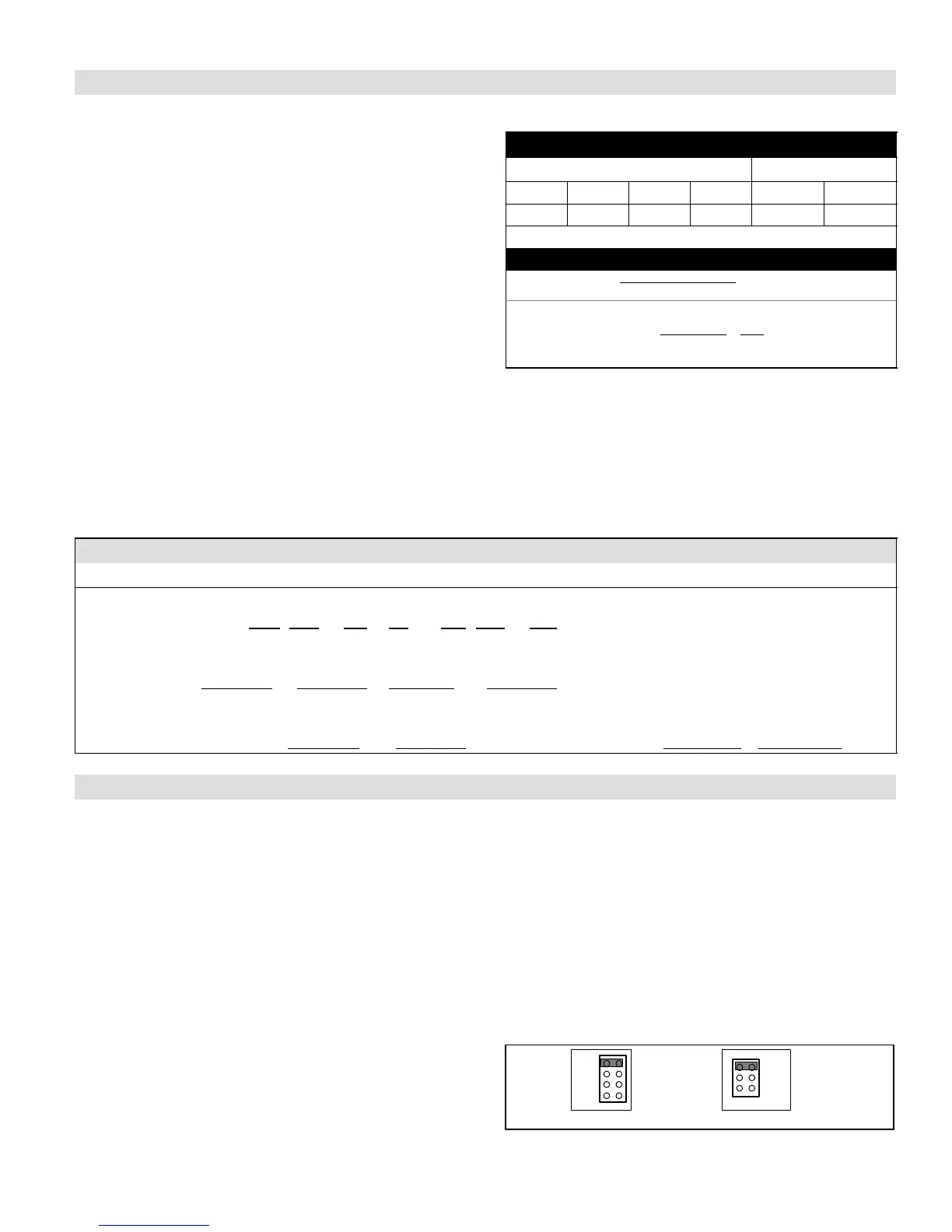

Table 5. Determine PIAB jumper setting

example CFM values

Required CFM CFM

Zone 1 Zone 2 Zone 3 Zone 4 Min. Max.

1020 1500 720 OFF 720 2200*

*High cool jumper setting

PIAB formula

100

(Req’d CFM − min. CFM)

(Max. CFM − min. CFM)

x

Using example values above, find PIAB for Zone 1:

PIAB (1020 − 720) = 300 =.20. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(2220 − 720) =1500. . . . . . . . . . . . . . . . . . . . . . .

PIAB Jumper setting % .20 x 100 20%. . . . . . . . . . . . . . . . . . . .

SETUP TIP!

PIAB calculations should provide a good starting point for

setting jumpers. It may also be beneficial to set jumpers at

a higher percentage of airflow such that the sound of air

rushing is objectionable, and then reduce it incrementally

by 10% until: 1) the sound of air rushing is not objection-

able, and 2) ample, but not excessive, air volume is being

provided to adequately heat or cool the zone.

PIAB Calculation Example (see worksheet on Page 60 )

PIAB = [(Required CFM − Minimum CFM) / (Maximum CFM − Minimum CFM)] * 100

Sample CFM ' Required Minimum Maximum Minimum

Sample PIAB = ([___920 − 450 ] / [ 2000 − 450 ]) x 100

==

bb

Sample PIAB = ([ 470 ] / [ 1550 ]) x 100

=

b

Sample PIAB = [ 0.303 ] x 100 = 30 %

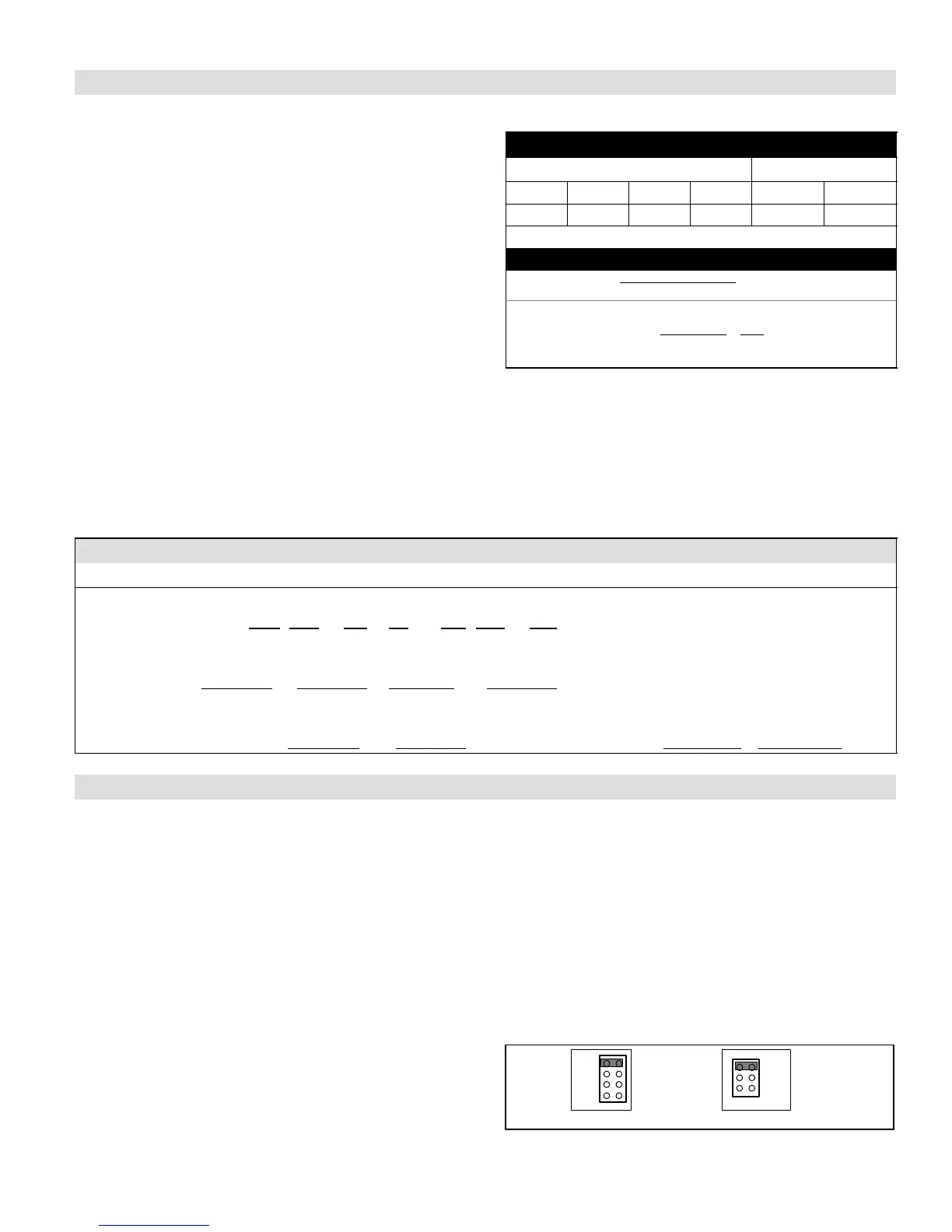

Zone Control Panel Jumpers (Air Reduction)

Continuous Air Reduction Jumpers

During continuous fan mode without either a heating or

cooling demand, the blower runs at the total percentage of

the CFM jumper settings of the zones calling for continu-

ous fan (not to exceed 100% of blower capacity). A contin-

uous air reduction jumper allows the blower speed to be re-

duced by a percentage during continuous fan mode.

The selections are 75%, 50%, 25% and 0%. At the factory,

the jumper is set on 0%. Set the jumper to the position

equal to the amount of continuous air reduction desired.

See figure 9.

NOTE − If the calculations using a reduction percentage

indicated a resulting CFM lower than the blower’s mini-

mum CFM rating, the blower will deliver its minimum CFM

(see figure 6 on Page 8).

Heating Air Reduction Jumpers

NOTE − For heat pump applications, ALWAYS set the

jumper on 0%. High head pressures may result if air is re-

duced during heating mode.

NOTE − For use in warm−climate areas where units have

high cooling capacity with low heat capacity, ALWAYS set

the jumper on 0%.

The heating air reduction jumper enables the blower

speed, during heating only, to run at a reduced rate

compared to the cooling blower speed.

The selections are 40%, 20% and 0%. Jumpers are set to

0% from the factory. Set the jumper to the position equal to

the amount of heating air reduction desired. See figure 9.

CONTINUOUS HEATING

0%

20%

40%

75%

50%

0%

25%

factory

settings

shown

heating jumper

Must be set on 0%

for heat pump

application

Figure 9. Air Reduction Jumper Settings

Loading...

Loading...