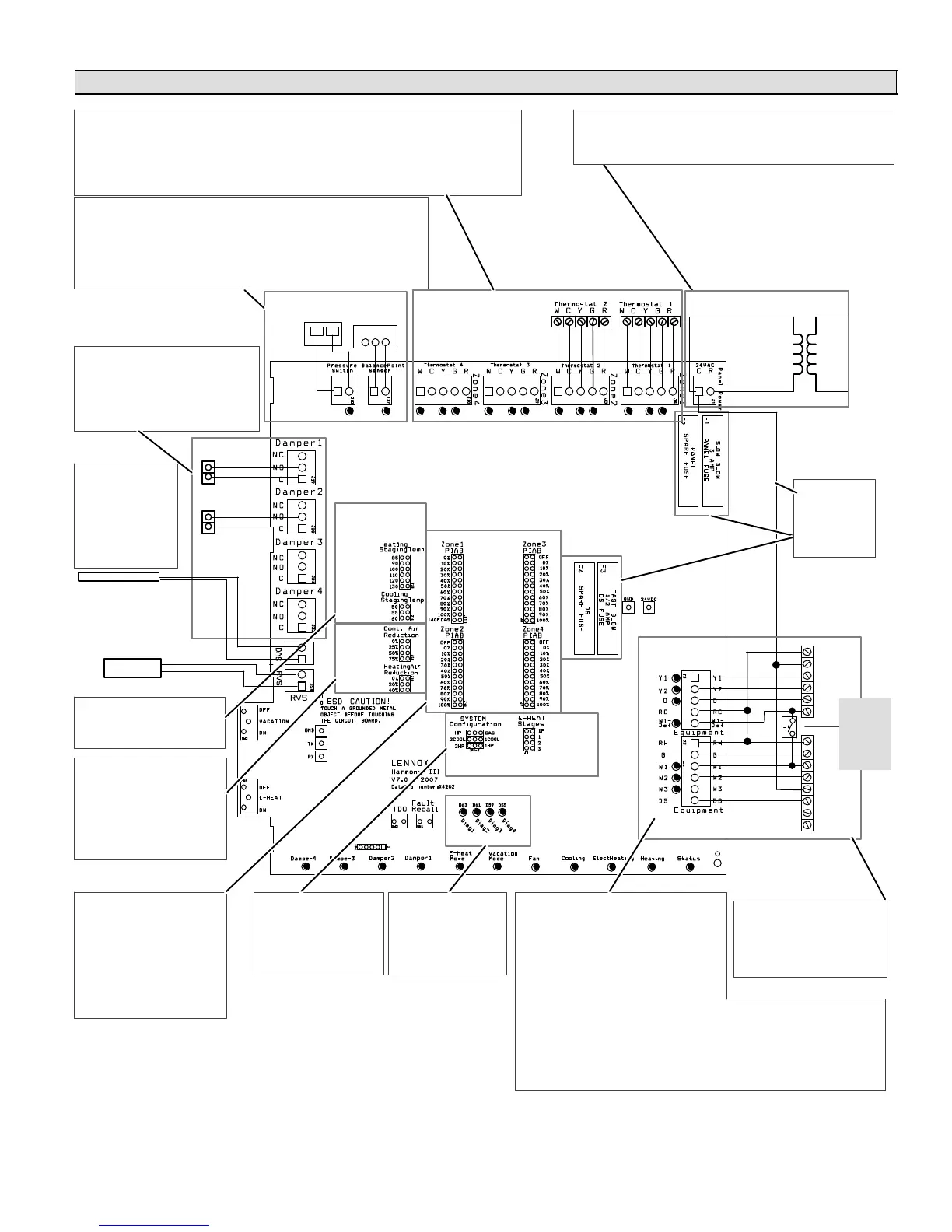

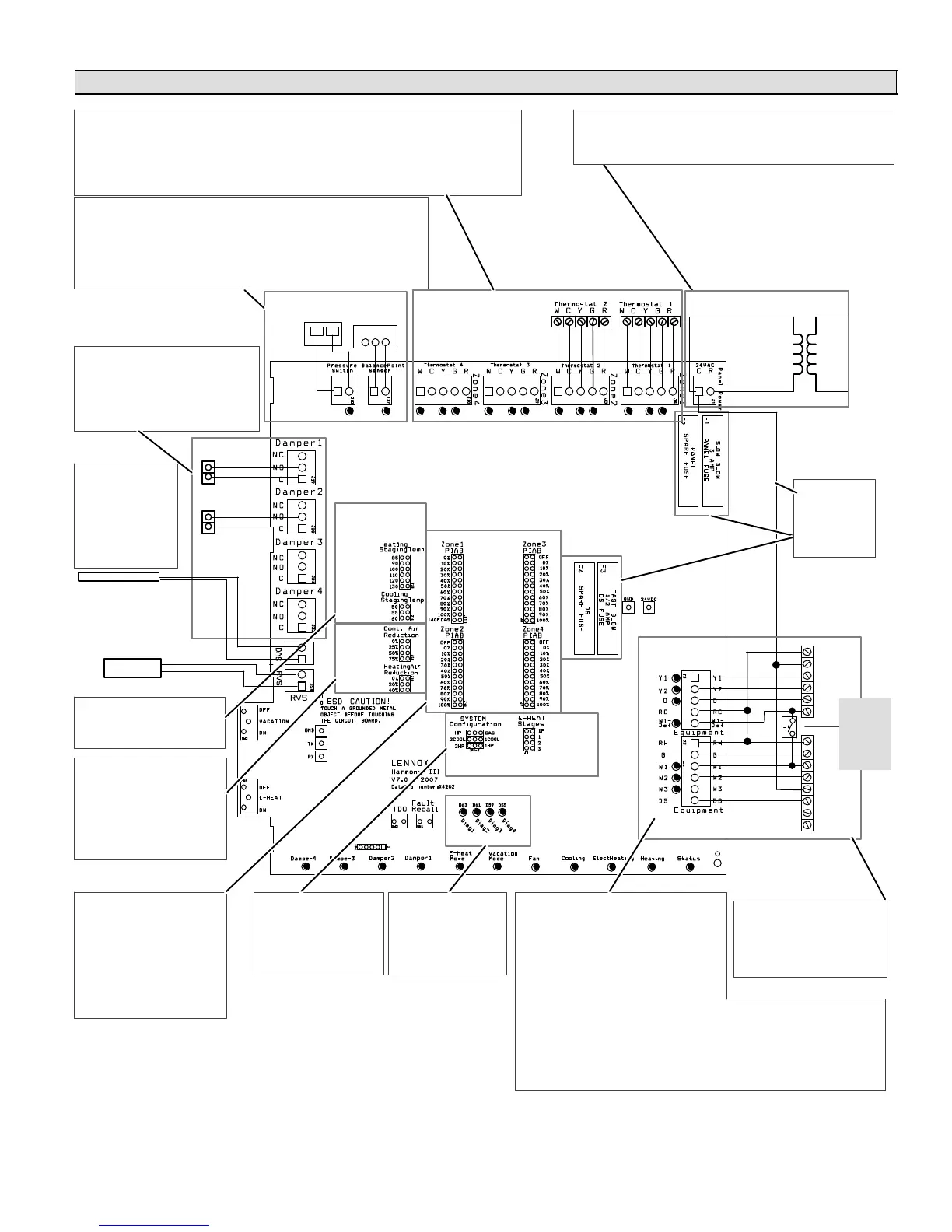

DUAL FUEL

Page 47

HARMONY IIIT ZONE CONTROL SYSTEM

TroubleshootingZoning system with Dual Fuel

- Do dampers respond to demand? 0

volts AC = open. 24 volts AC =

closed. Dampers should drive closed

when 24 volts is jumpered to damper

motor.

- Is wiring correct & in good condition?

- Are thermostats wired correctly?

- Does zone control system respond appropriately to demand?

- Does electronic thermostat have relay switching output? If relay with SCR output is used, not, isola-

tion relays may need to be used.

- 24VAC supplied to each thermostat terminal R from zone control system?

- Check each thermostat for output signal when calling. Heating output W1? Cooling output Y1?

- Error code present?

If so, see trouble-

shooting/diagnostic

section of this

manual (Page 56).

- Are jumpers set correct-

ly for heating and cool-

ing? (Page 11)

- Does outdoor unit respond to demand?

- Is it operating properly?

- Test Defrost. Does outdoor unit initiate and

terminate defrost correctly?

- Check defrost tempering switch, if installed.

- Does zone control system respond

appropriately during defrost?

- Are appropriate outputs energized in

response to demand?

- Does zone control system energize appropriate outputs? During Cooling? During

Heating? During Defrost? During Emer. Heating?

- 24VAC from furnace transformer to R?

- Does indoor unit respond to outputs? Cooling? Heating? Defrost? Emer. Heating?

- Does blower speed change as zone demand changes? If no, does DS output vary

from 0 to 25VDC?

- Line Voltage to transformer?

- 24VAC from transformer to zone control panel?

- Are all wire connections good? Are all wire connections correct?

- Pressure Switch installed. in correct position?

- Does switch open when high pressure condition is simulated (temporarily

blocking airflow in heating mode)?

- Does zone control system respond appropriately when high pressure condi-

tion is simulated (temporarily disconnecting switch simulates high pressure).

- Balance Point Sensor Installed and correctly wired?

- Contacts close on temperature fall?

DAMPERS

System Configuration & E−Heat

jumper settings − page 11.

Heating/cooling

staging jumper

settings − page 10.

Heating

Cooling

120

VAC

24

VAC

THERMOSTATS

- Are PIAB jumpers set cor-

rectly?

- Only 1 jumper per Zone?

(Zone Control System Jump-

er Settings (Page 8) (NOTE:

Zone 1 may have a second

jumper on 140F DAS pins)

- Has 140F DAS jumper been

installed (if required; see

Page 8 & 10)?

- Are continuous & heating air

reduction jumpers set correct-

ly? On heat pumps, Heating

Air Reduction must be 0%.

- Do jumpers provide appropri-

ate speed reduction? If no,

check indoor unit before re-

placing zone control panel.

- Have heating and cooling

staging jumpers been set

for desired 2nd stage op-

eration?

PRESSURE

SWITCH

1 2 3

BALANCE

POINT

SENSOR

140F DAS

jumper pgs

8 & 10.

R

C

Y1

Y2

O

W1

R

G

W1

W2

C

DS

Y1

Y2

HEAT PUMP

VARIABLE

SPEED

FURNACE

PIAB jumper settings − page 8.

DT2 (S89)

Limit Con-

trol (Op-

tional, for

defrost

tempering

kit)

- Is discharge

probe installed?

- Is probe located

in discharge air

plenum as de-

scribed on

Page 6?

- Is it wired cor-

rectly?

DISCHARGE

AIR SENSOR

HUMIDITROL ZONING

ACCESSORY CONTROL

- C" connected

to C"?

- Fuses OK?

TO FURNACE

POWER SUPPLY

- Verify Furnace jumpers/

links cut or removed

(see Pages 28 − 25)

- Verify NO connections

made to Y1 or Y2.

Air

reduction

jumper

settings −

page 9.

ZONE PANEL TRANSFORMER

Figure 28. Option 3 − Lennox Heat Pump & Lennox Variable-Speed Gas Furnace (Dual Fuel)

Loading...

Loading...