DUAL FUEL

Page 45

HARMONY IIIT ZONE CONTROL SYSTEM

Dual Fuel Gas Heating Checkout (Multiple Zone)

Prerequisites:

S

All zone thermostats set to Heat.

S Balance Point Sensor set at higher temperature than outdoor

BPS-sensed temperature (red balance point sensor LED

on).

OR

S Balance Point Sensor inputs jumpered to simulate cold out-

door temperature below balance point (red balance point

sensor LED on).

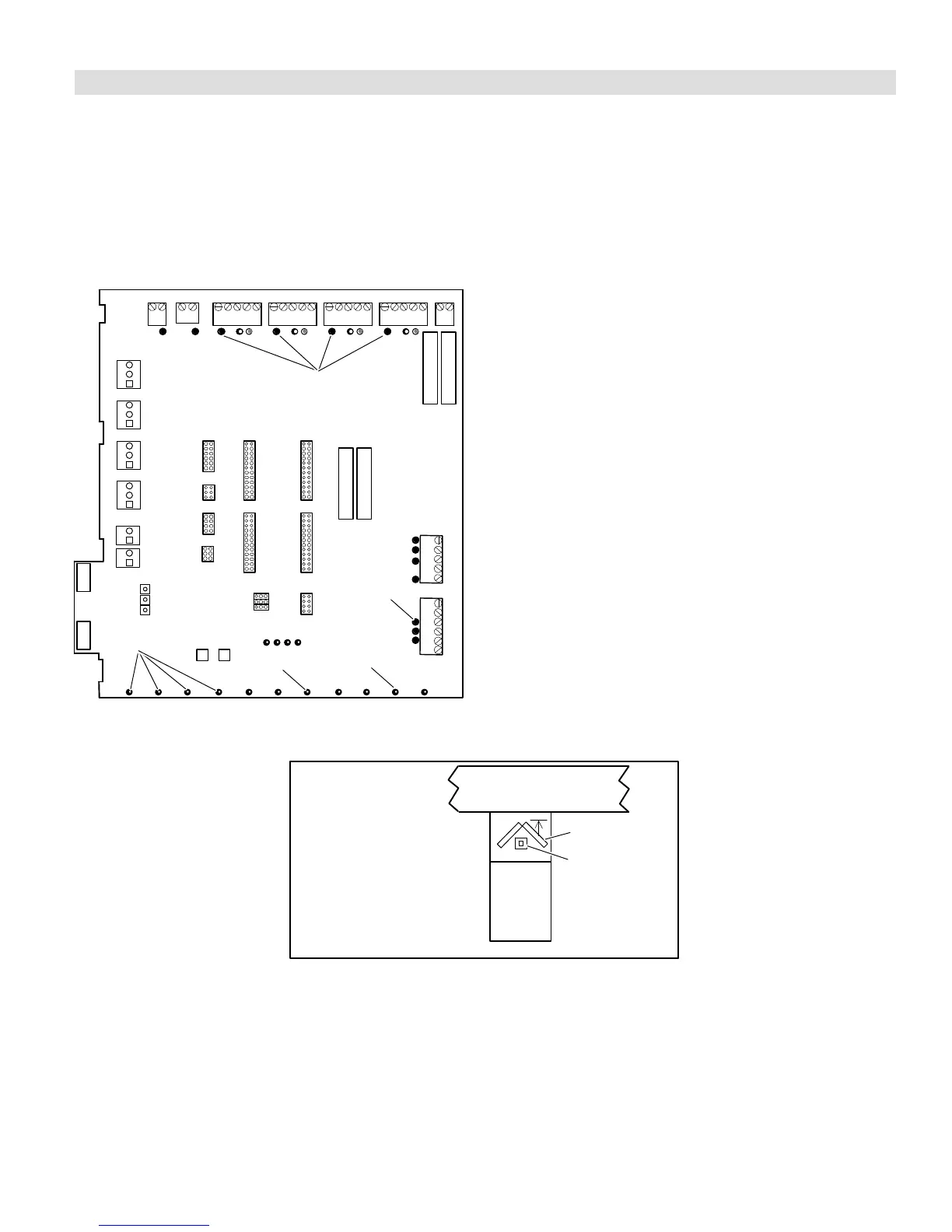

OUTPUT STATUS LEDs

DAMPER 2,3,4 OFF

W1 ON

(W) RED ON

HEATING ON

FAN ON

1. Set all zone thermostats for a heat demand; check for

the following:

D All zone thermostat W LEDs on (heat demands).

D LEDs dampers 1 − 4 off (all dampers open).

D Output Heat W1 LED on (furnace on).

D Heating LED on.

The furnace begins ignition sequence after a heat de-

mand is detected. The zone control system will start

the furnace blower on low speed (0 PIAB) 45 seconds

after the combustion cycle has begun.

2. When 100ºF warm air is sensed by the discharge air

sensor, the fan LED comes on and the blower will

slowly increase to speed required by the zones calling.

The blower operates at a speed equivalent to the sum

of all zone PIAB jumpers but at a maximum not to ex-

ceed the setting of the heating air reduction jumper. It

may take the blower 60 to 90 seconds to reach this

speed.

3. Set all zone thermostats for NO heat demands; check:

D Output Heat W1 LED off.

D Heating LED off.

D Fan LED off (blower turns off after delay).

D All zone thermostat W LEDs off.

D DamperLEDs − Last zone thermostat demand re-

moved: LED is off (this zone’s damper remains

open during 3−1/2 minutepurge); other zones

damper LEDs are on during the 3−1/2 minute

purge (dampers closed). After 3−1/2 minute delay,

all dampers LEDs go off (dampers open).

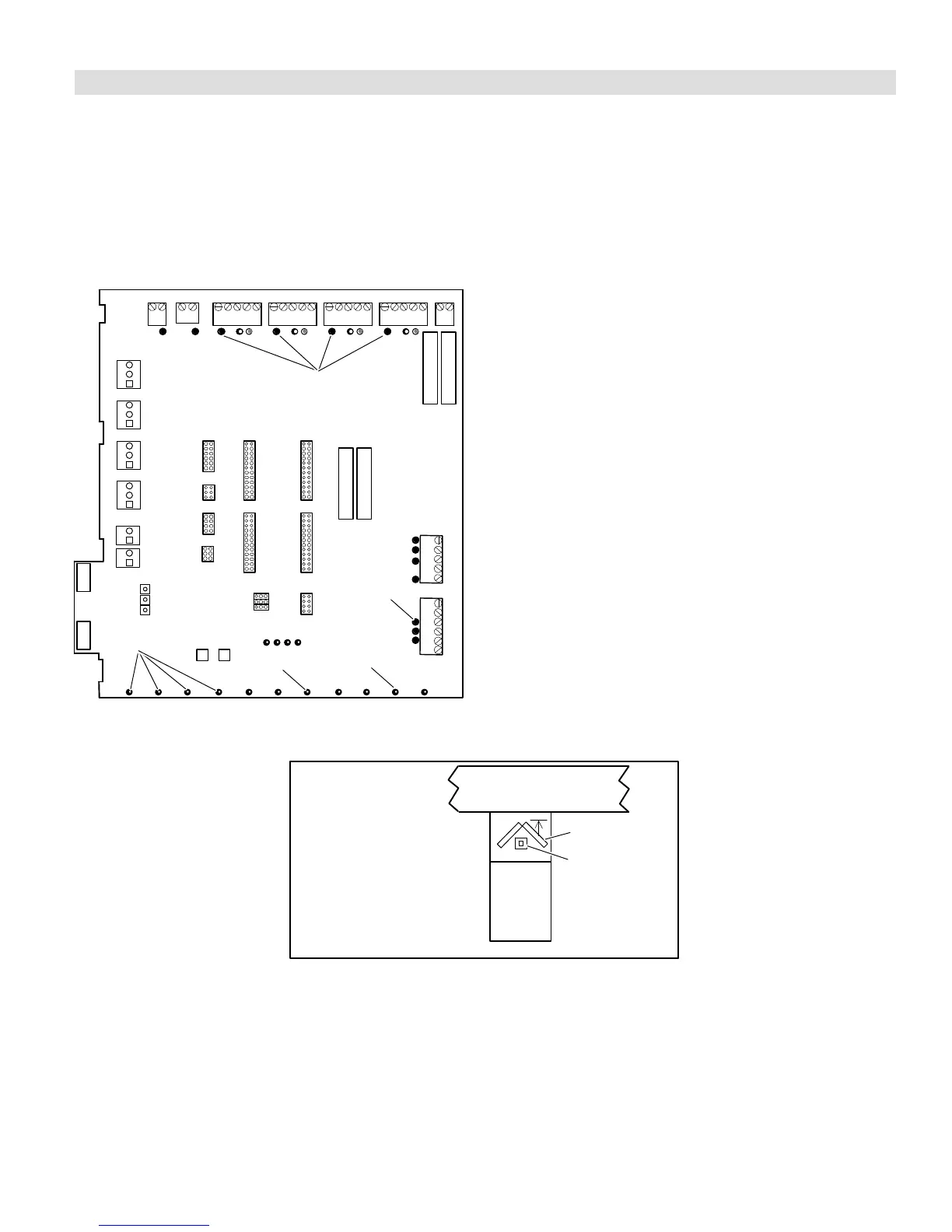

Defrost Tempering (Kit 67M41)

plenum

coil

furnace

front

defrost tempering

sensor/limit con-

trol (if used in

Option 3)

Install the defrost tem-

pering sensor (if used)

where shown. (See

504,797M installation in-

structions.)

Typical Upflow

Furnace Shown

Figure 27. Defrost Tempering Sensor Placement

Loading...

Loading...