MAINTENANCE SERVICE MANUAL NUMBER 23

Page 1B-42 90-861326--1 MARCH 1999

Inspecting

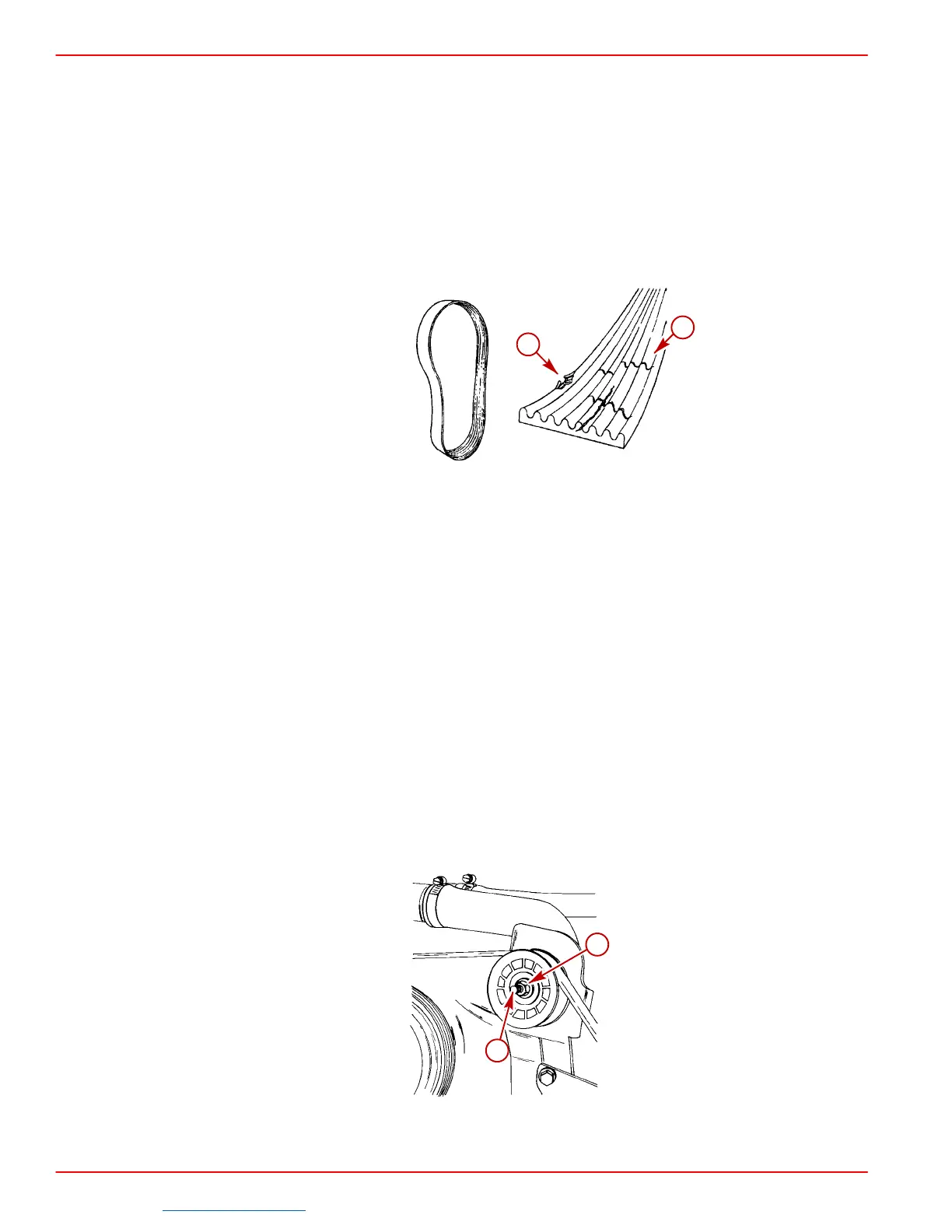

1. Inspect drive belt for the following:

• Excessive wear

• Cracks

NOTE:

Minor, transverse cracks (across

the belt width) may be acceptable. Longitudinal

cracks (in direction of belt length) that join transverse cracks are NOT acceptable.

• Fraying

• Glazed surfaces

75130

b

a

a-Fraying

b-Cracks

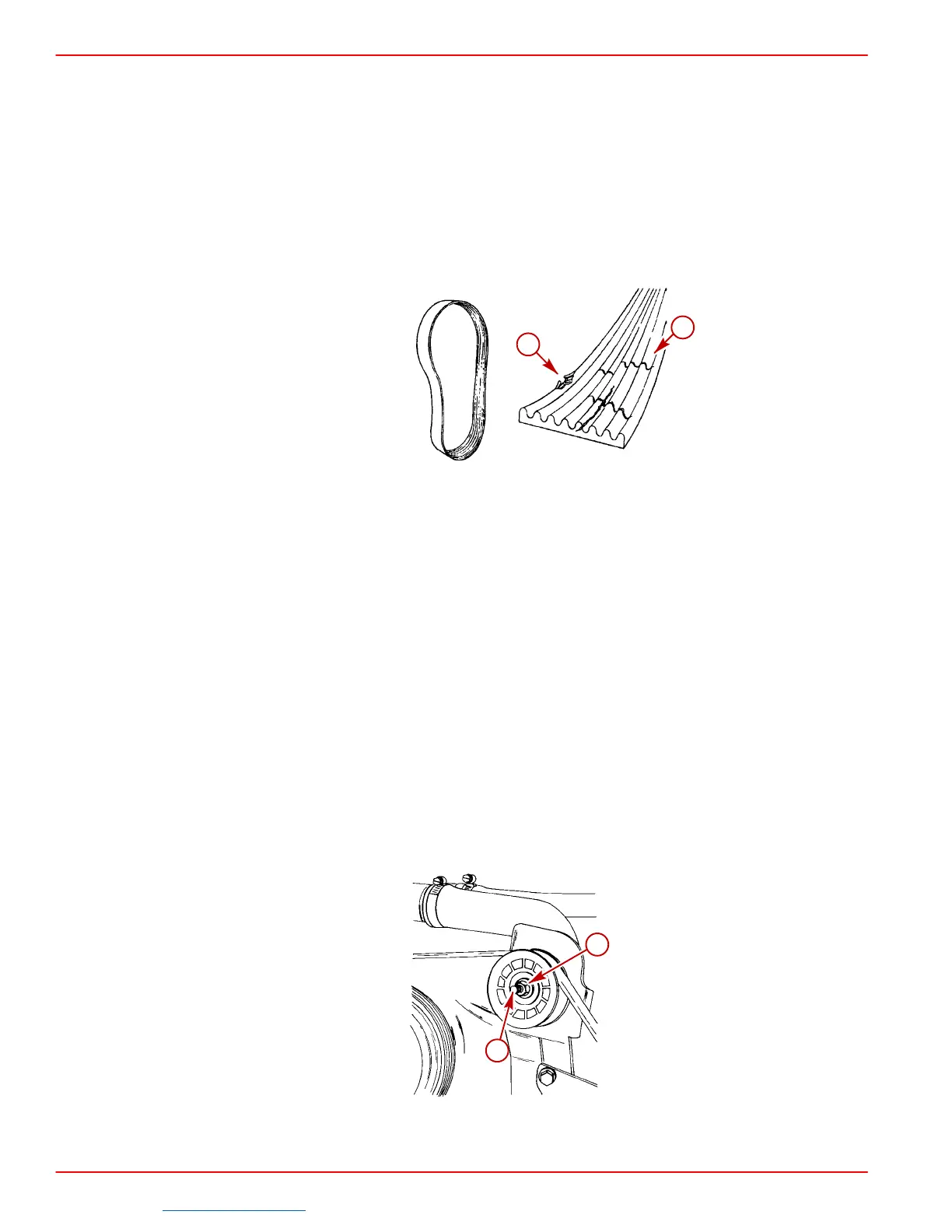

Replacing and/or Adjusting Tension

1. Remove drive belt as follows:

a. Loosen 5/8 in. locking nut on adjustment stud.

b. Turn adjustment stud and loosen belt. Remove belt.

2. Install drive belt on pulleys and adjust tension as follows:

a. Loosen 5/8 in. locking nut on adjustment stud. Leave wrench on adjustment stud.

NOTE: Belt deflection is to be measured on the belt at the location that has the longest dis-

tance between two (2) pulleys. Proper tension is 1/4 in. (6 mm) deflection with moderate

thumb pressure.

b. Use 5/16 in. socket and tighten adjusting stud until the correct deflection of the belt

is obtained at location specified above.

c. While holding adjustment stud at the correct belt tension, tighten 5/8 in. locking nut.

d. Run engine for a short period of time and recheck belt adjustment.

74908

a

b

a-5/8 in. Locking Nut

b-5/16 in Adjusting Stud

Downloaded from https://needmanual.com/!

Loading...

Loading...