FUEL SYSTEM

8-17

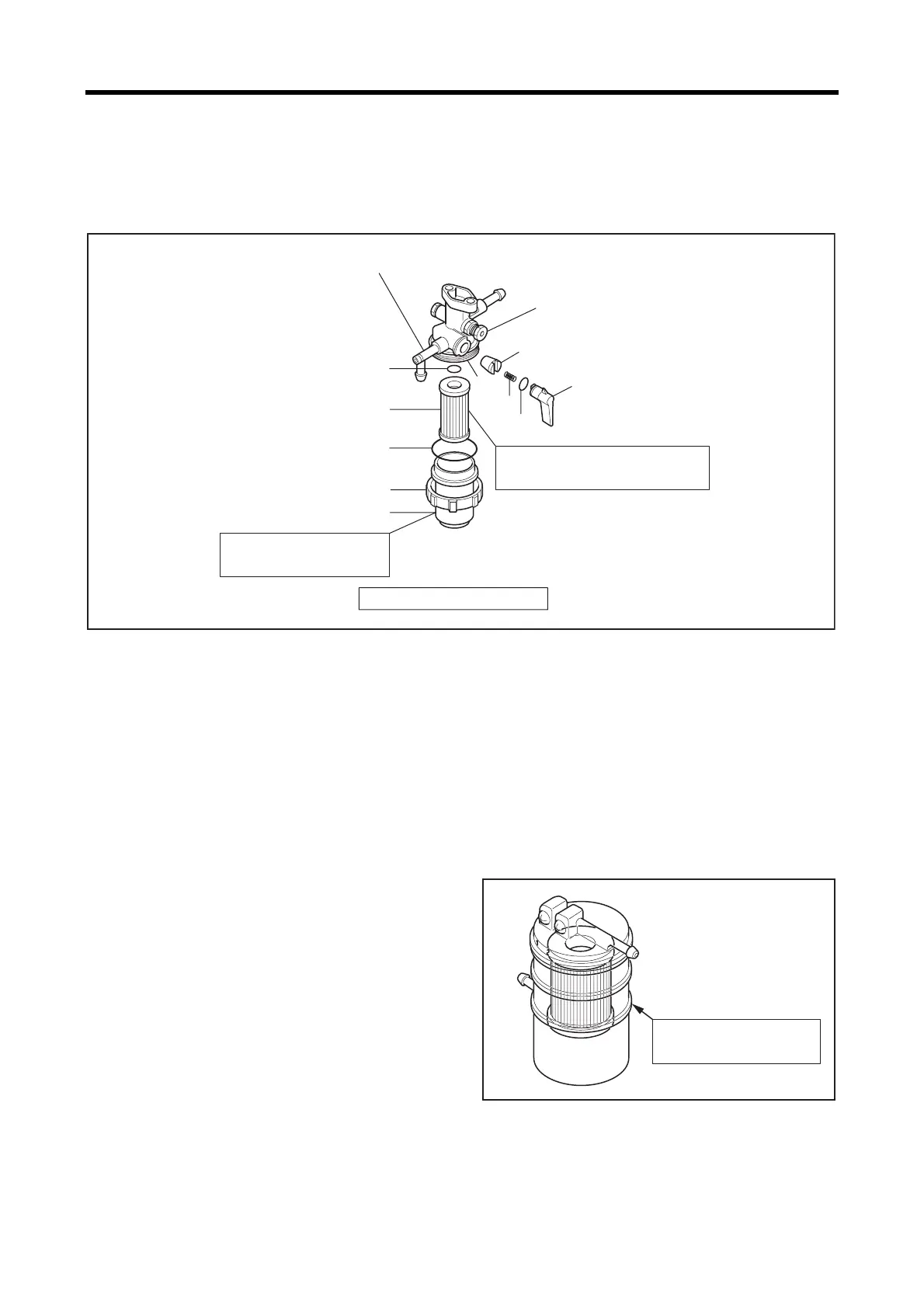

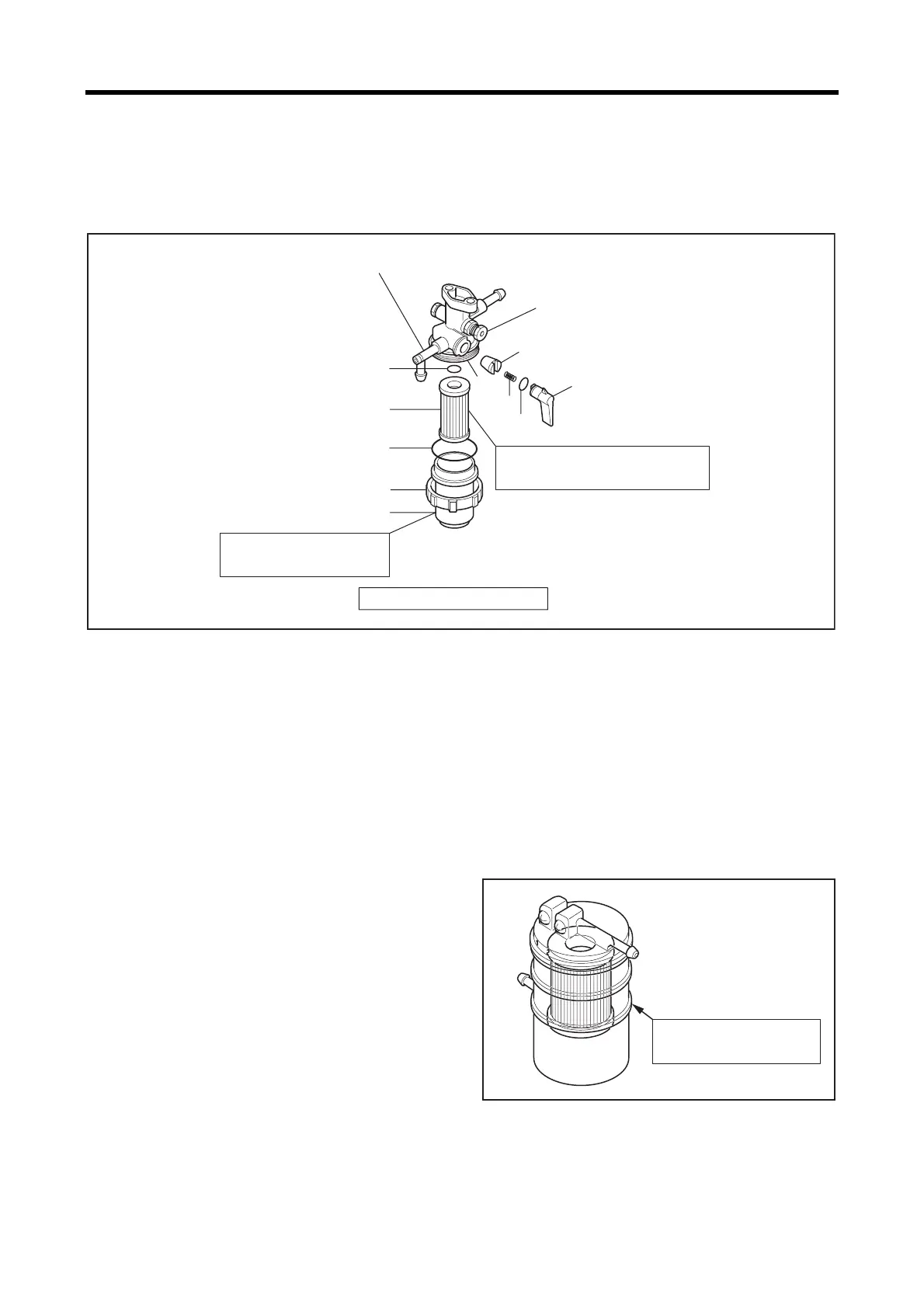

2.5 Fuel filter

2.5.1 Disassembling, inspecting and reassembling fuel filter

Disassembling, inspecting and reassembling fuel filter

Disassembling sequence

Note: (a) Disassemble the fuel filter only when removing the element. Do not disassemble the cock lever unless absolutely

necessary.

(b) When removing the cock lever and reassembling it after cleaning, apply silicon oil to the O-ring of the lever.

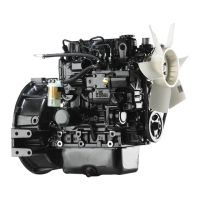

When dust or water is accumulated at the case bottom or in

the element, replace the filter as an assembly. Replace the

fuel filter every 400 hours. Check the filter every 100 hours.

If defective, replace the filter regardless of the replacement

interval.

Inspecting fuel filter (cartridge type)

3

4

5

1

2

10

8

7

9

6

Air bleed plug

Do not remove.

Wash in light oil: every 100 hours

Replace: every 500 hours

Check for accumulation of

water or sediment

Replace: O-rings (3, 5 and 7)

1 Ring nut 4 Element 7 O-rings 10 Filter body

2 Cup 5 O-rings 8 Spring

3 O-rings 6 Cock lever 9 Valve

Inspect: every 100 hours

Replace: every 400 hours

Replace the entire assembly

if water/sediment is

accumulated inside.

Loading...

Loading...