ELECTRICAL SYSTEM

12-32

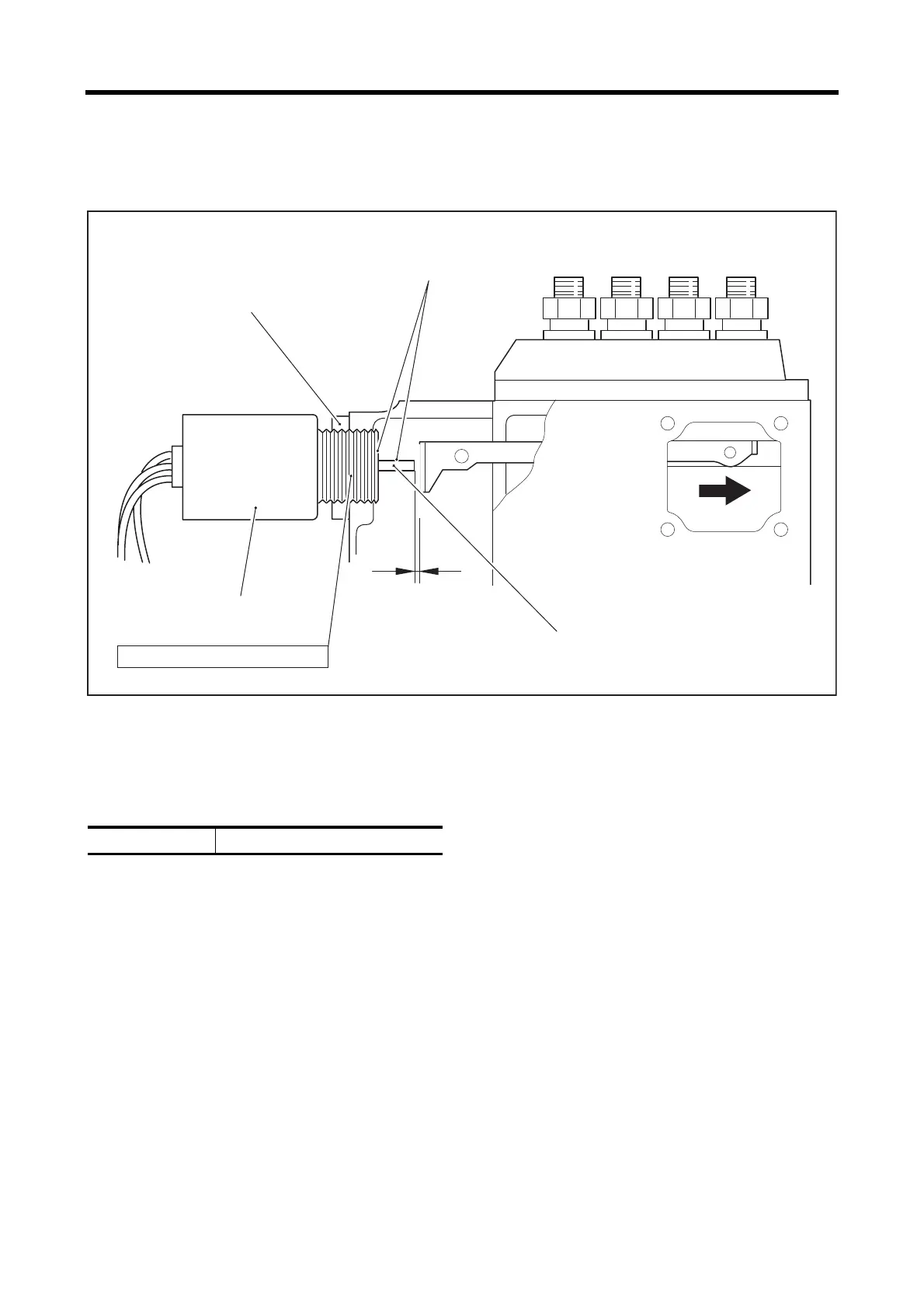

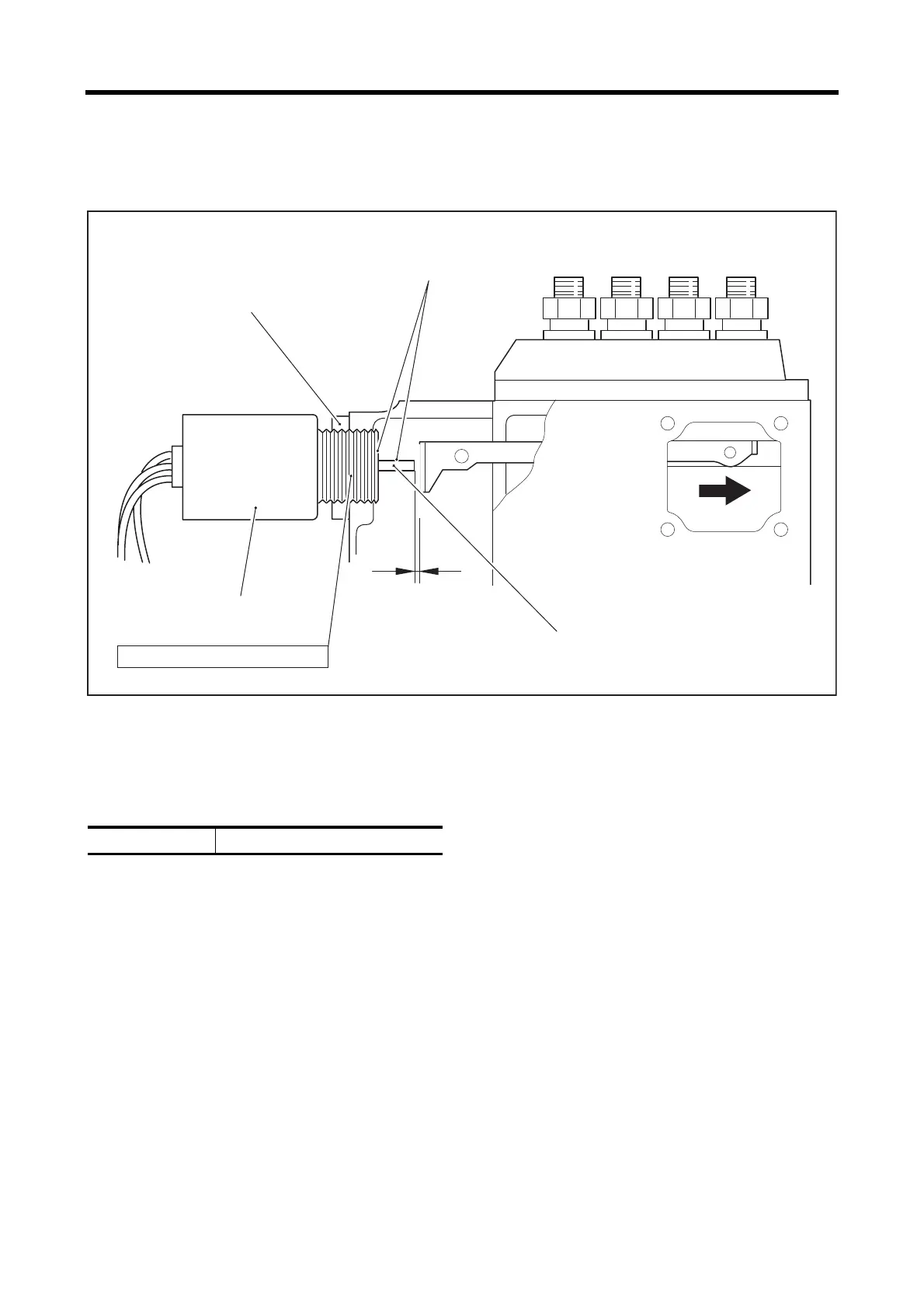

3.3 Installing stop solenoid (ETR type)

Installing stop solenoid (ETR type)

3.3.1 Procedure for installing stop solenoid (ETR type)

(1) Apply a sealant to the threaded portion of the stop solenoid.

Note: Apply the sealant up to the position where the stop solenoid is screwed into the governor case.

(2) Temporarily reassemble the stop solenoid and the nut to the governor case.

(3) Move the control rack of the fuel injection pump fully in the stop direction.

(4) Screw in the stop solenoid until the shaft contacts the tie rod.

(5) Turn the stop solenoid in the reverse direction by 30 to 45° from the above condition and temporarily tighten the nut.

(6) Move the control rack side to side and make sure that there is play of approx. 0.15 to 0.20 mm [0.0059 to 0.0079 in.].

(7) Tighten the nut to the specified torque.

3.3.2 Verification after reassembling (ETR type)

(1) After starting the engine, turn the starter switch key to the OFF position, and make sure that the stop solenoid activates

and the engine stops.

(2) After starting the engine, make a short circuit between the terminal of the oil pressure switch and the switch body, and

make sure that the engine stops.

Nut

39.2 to 49.0 N·m

{4.0 to 5.0 kgf·m}

[28.9 to 36.2 Ibf·ft]

0.15 to 0.20 mm

[0.0059 to 0.0079 in.]

These areas must be

free from sealants.

Threaded portion: Apply sealant.

Stop solenoid

Shaft

Sealant or lubricant THREEBOND 1212 or 1211

Loading...

Loading...