REASSEMBLY OF BASIC ENGINE

7-7

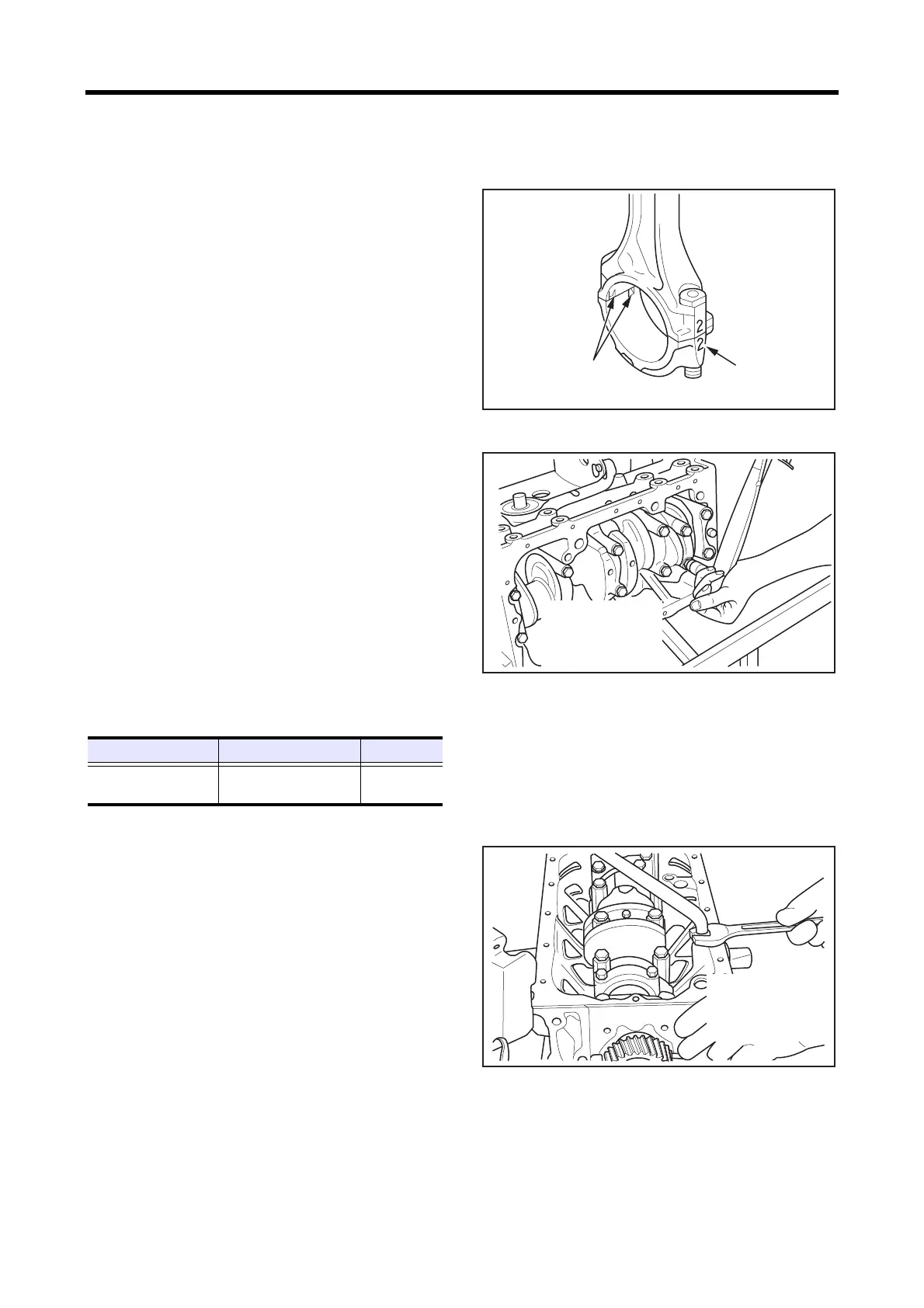

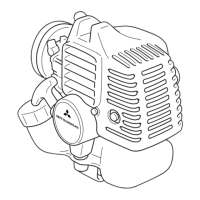

1.10 Installing connecting rod cap

(1)

When the big end of the connecting rod comes into

close contact with the crank pin, turn the crankshaft

180° while pressing the piston head.

(2) Fit the connecting rod bearing (lower) to the rod cap

with the lug aligned with the lug groove.

(3) Install the cap to the connecting rod, aligning the

mating marks made during disassembly.

Note: For new connecting rod on which there is no mating

mark, orient the lugs of upper and lower bearings on

the same side as shown in the illustration.

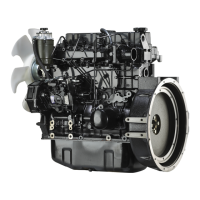

(4) Tighten the connecting rod cap nuts evenly and

progressively to the specified torque.

(5) Inspect end play of the connecting rod. If end play is

small, loosen and retighten the cap nuts.

Installing connecting rod caps

Tightening connecting rod cap nuts

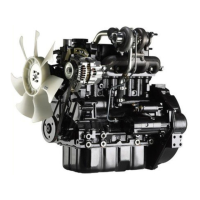

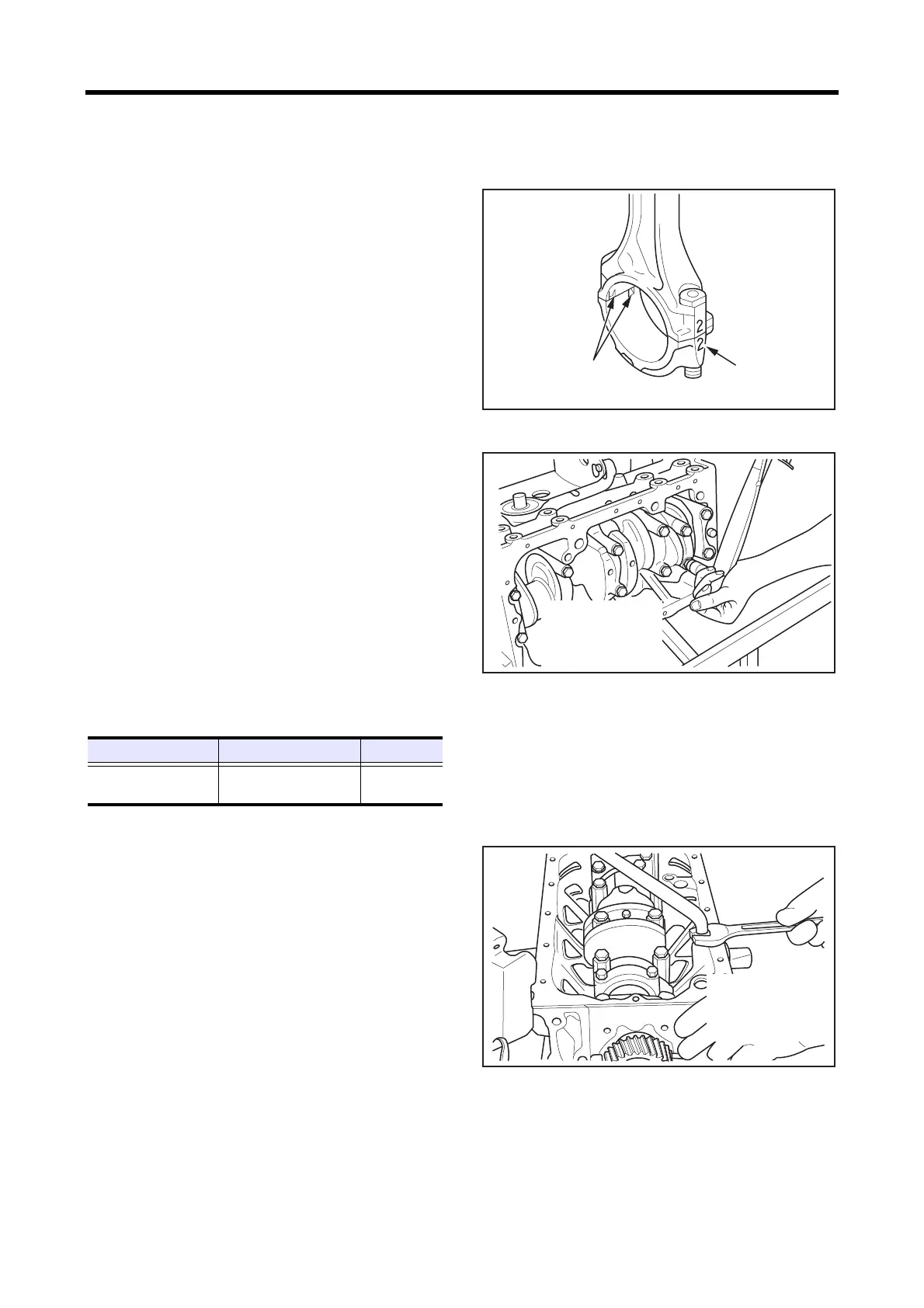

1.11 Installing oil strainer

(1)

Invert the cylinder block to face up the oil pan

mounting surface.

(2) Make sure that the end of the strainer does not contact

to oil pan, install the strainer and tighten the nut to the

specified torque.

Installing oil strainer

Item Standard Limit

End play of connecting

rods

0.10 to 0.35 mm

[0.0039 to 0.0138 in.]

0.50 mm

[0.0197 in.]

Lug groove

Cylinder No.

32.4 to 37.3 N·m

{3.3 to 3.8 kgf·m}

[23.9 to 27.5 lbf·ft]

24.5 to 29.4 N·m

{2.5 to 3.0 kgf·m}

[18.1 to 21.7 lbf·ft]

Loading...

Loading...