REASSEMBLY OF BASIC ENGINE

7-6

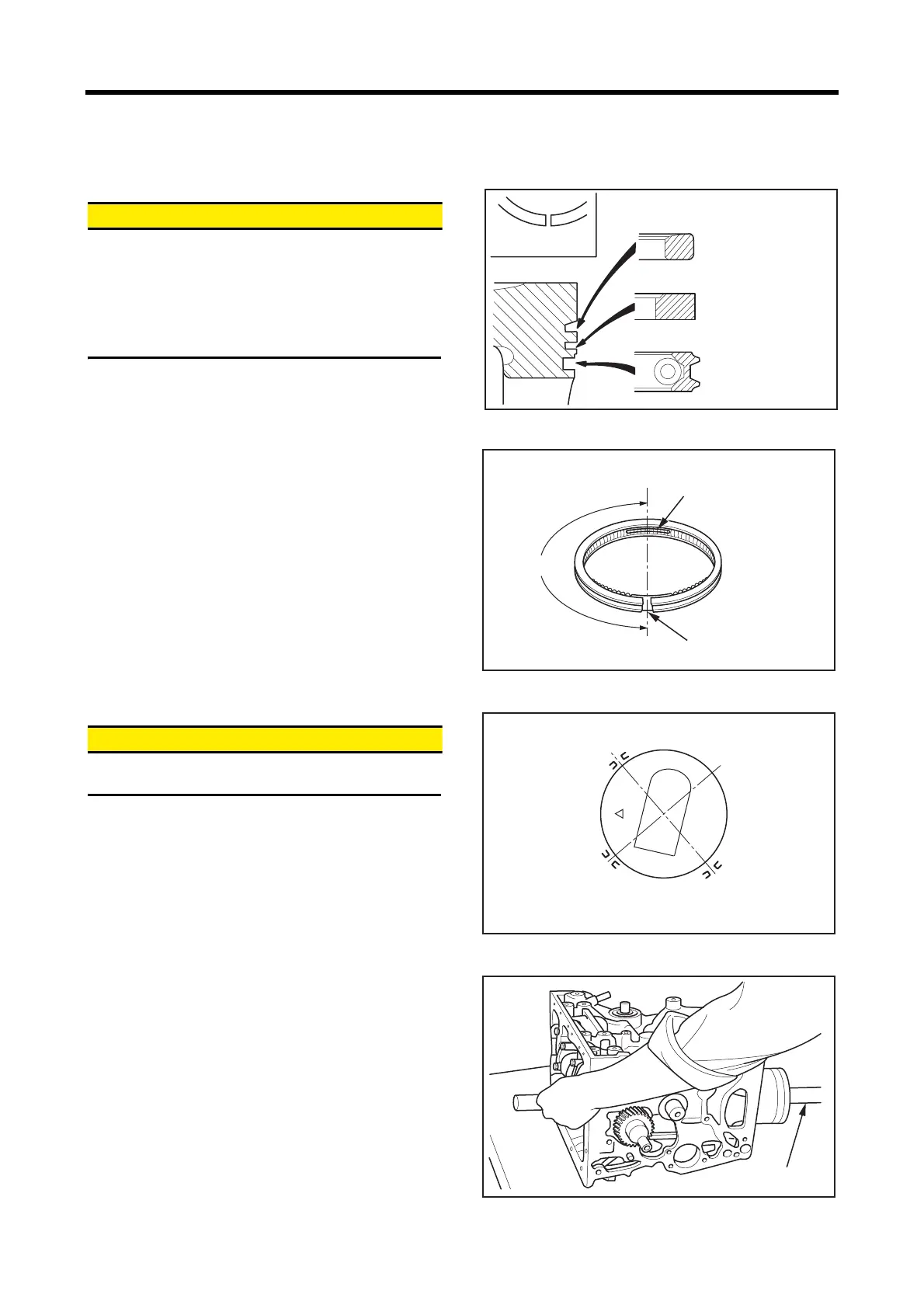

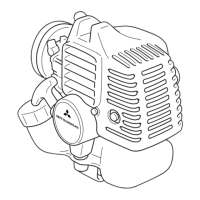

1.8 Installing piston ring

&$87,21

Every piston ring has a top mark such as “R” near the

end gap. Install all piston rings with this mark facing

upward.

If the rings are installed upside down, it could cause

malfunctions such as excessive oil consumption or an

engine seizing.

(1) Install the piston rings to the piston with a piston ring

plier.

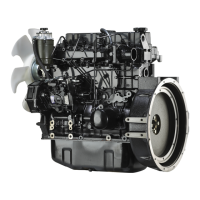

(2) Install the oil ring with its end gap 180° away from the

joint of the coil spring, as shown in the illustration.

Piston/piston ring orientation

Reassembling oil ring

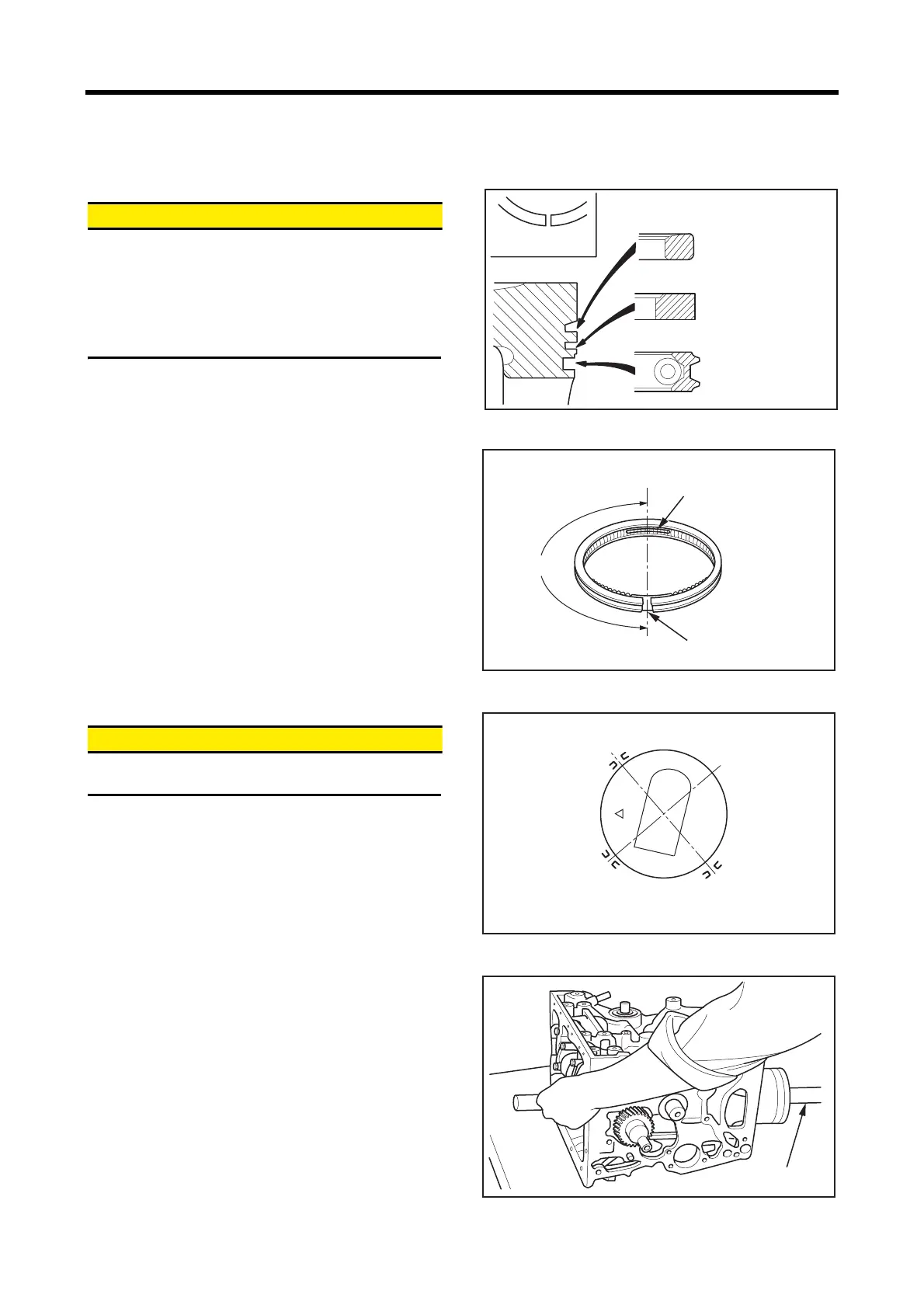

1.9 Installing piston and connecting rod

&$87,21

Do not forcefully insert the piston, as it may cause

damage to the piston rings and crank pin.

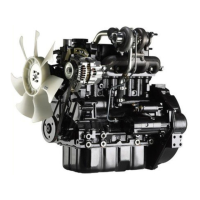

(1) Apply engine oil to the circumference of the piston and

piston rings.

(2) Place the ring end gaps in diagonal positions avoiding

the piston pin direction and its right angle direction.

(3) Fit the connecting rod bearing (upper) to the connecting

rod aligning the lug and lug groove.

(4) Turn the crankshaft to place the crank pin of the

assembling cylinder to the top dead center.

(5) Face the front mark (arrow) stamped on the piston top

toward the timing gear case side (forward of the

engine).

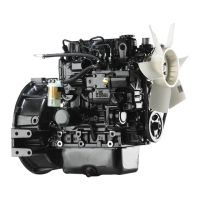

(6) Insert the piston from the top face of cylinder block

using a piston guide (commercially available).

Orienting piston ring end gaps

Installing pistons and connecting rods

T

Oil ring

No.1

compression ring

No.2

compression ring

Top face mark

Piston ring plier

P/N: 31391-12900

Oil ring abutment

Coil spring butted ends

180°

Oil ring end gap

No.1 compression

ring end gap

Front of

engine

No. 2 compression

ring coil spring butt joint

Piston guide

Loading...

Loading...