LUBRICATION SYSTEM

9-4

2. Disassembling, inspecting and reassembling lubrication system

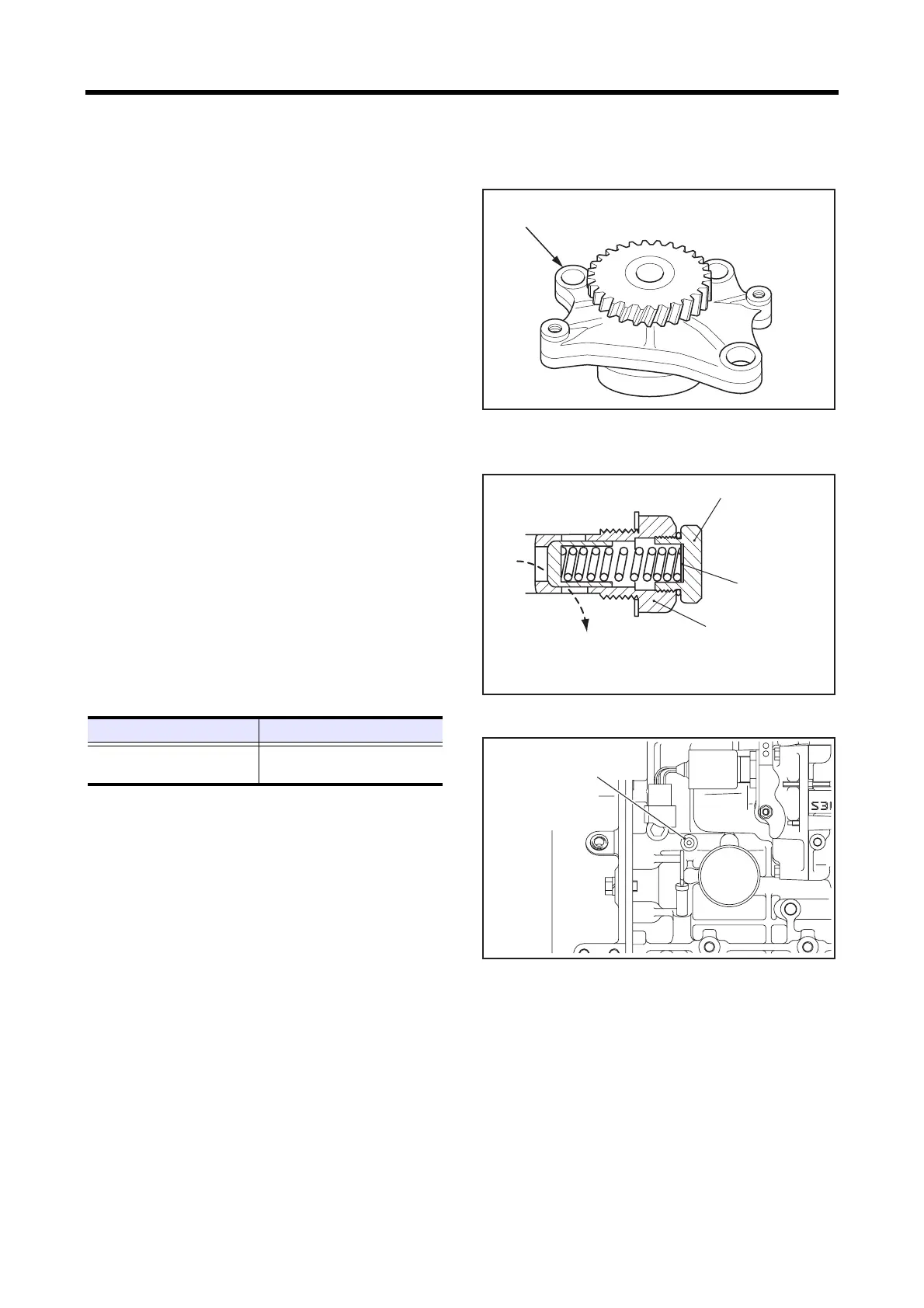

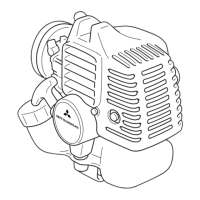

2.1 Inspecting the oil pump

Check the oil pump for any damage, and whether or not it

rotates smoothly. If faulty, replace the entire pump

assembly.

Inspecting oil pump

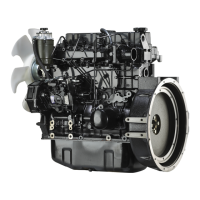

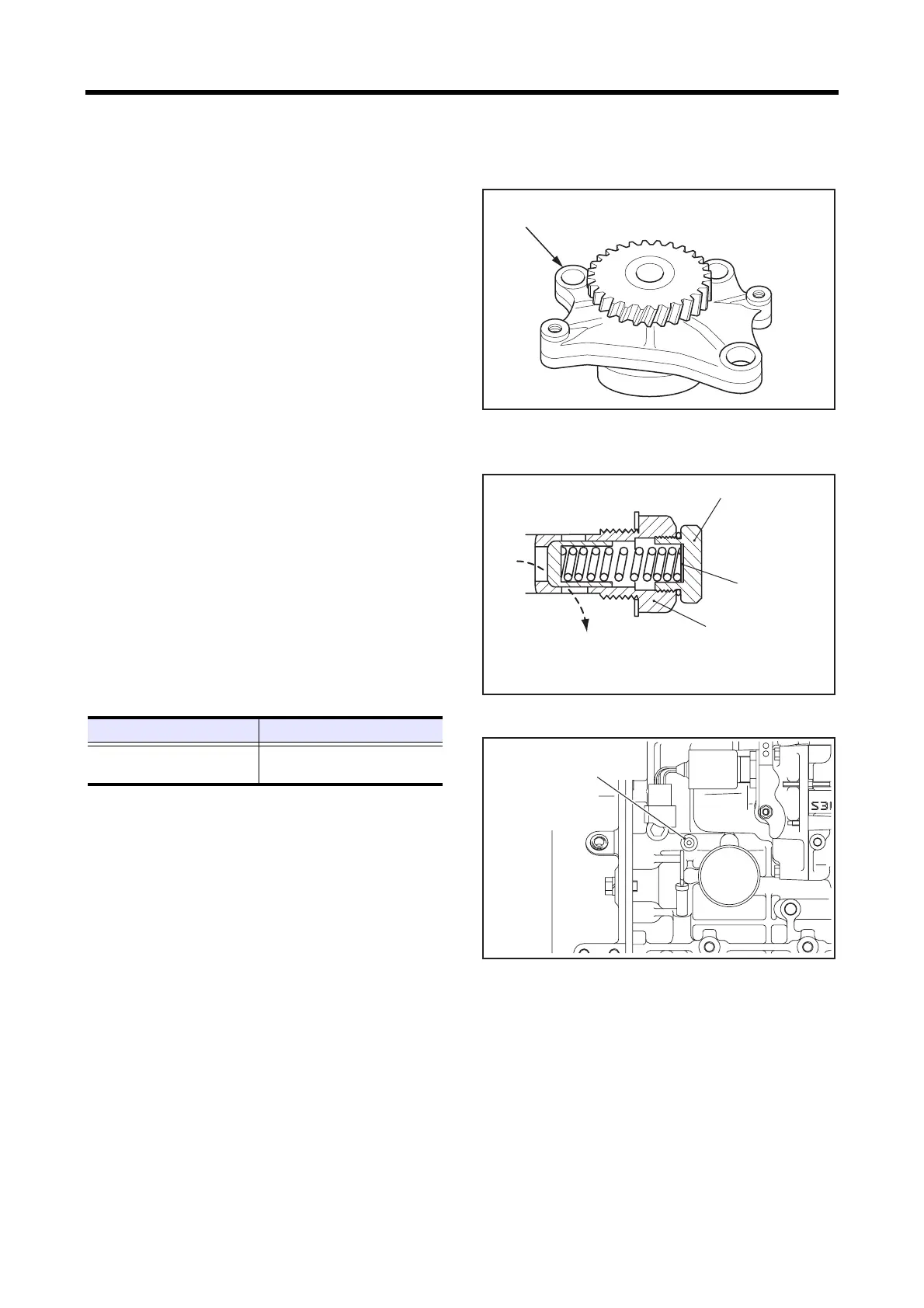

2.2 Inspecting relief valve

(1)

Check the relief valve and its valve seat for contact

condition. Check the spring for fatigue and damage. If

it is faulty, replace the relief valve with new one.

(2) Measure the valve opening pressure (oil pressure when

the engine is running at rated speed) of the relief valve.

If the measured value is out of the standard, remove the

plug and make an adjustment by increasing and

decreasing the shim thickness.

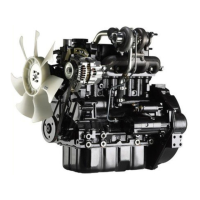

Engine oil pressure take-out port

Next to the oil filter Rp 1/8 thread (PS 1/8)

Inspecting relief valve

Engine oil pressure measuring port

Inspect for damage and smooth rotation

Item Standard

Relief valve opening pressure

0.3 to 0.4 MPa {3 to 4 kgf/cm²}

[43 to 57 psi]

Plug

44 ± 4.9 N·m

{4.5 ± 0.5 kgf·m}

[32.5 ± 3.6 lbf·ft]

Shim

Valve housing

49 ± 4.9 N·m

{5 ± 0.5 kgf·m}

[36.2 ± 3.6 lbf·ft]

Engine oil pressure

measuring port (Rp 1/8)

(Engine oil

pressure switch

installation part)

Loading...

Loading...