REASSEMBLY OF BASIC ENGINE

7-4

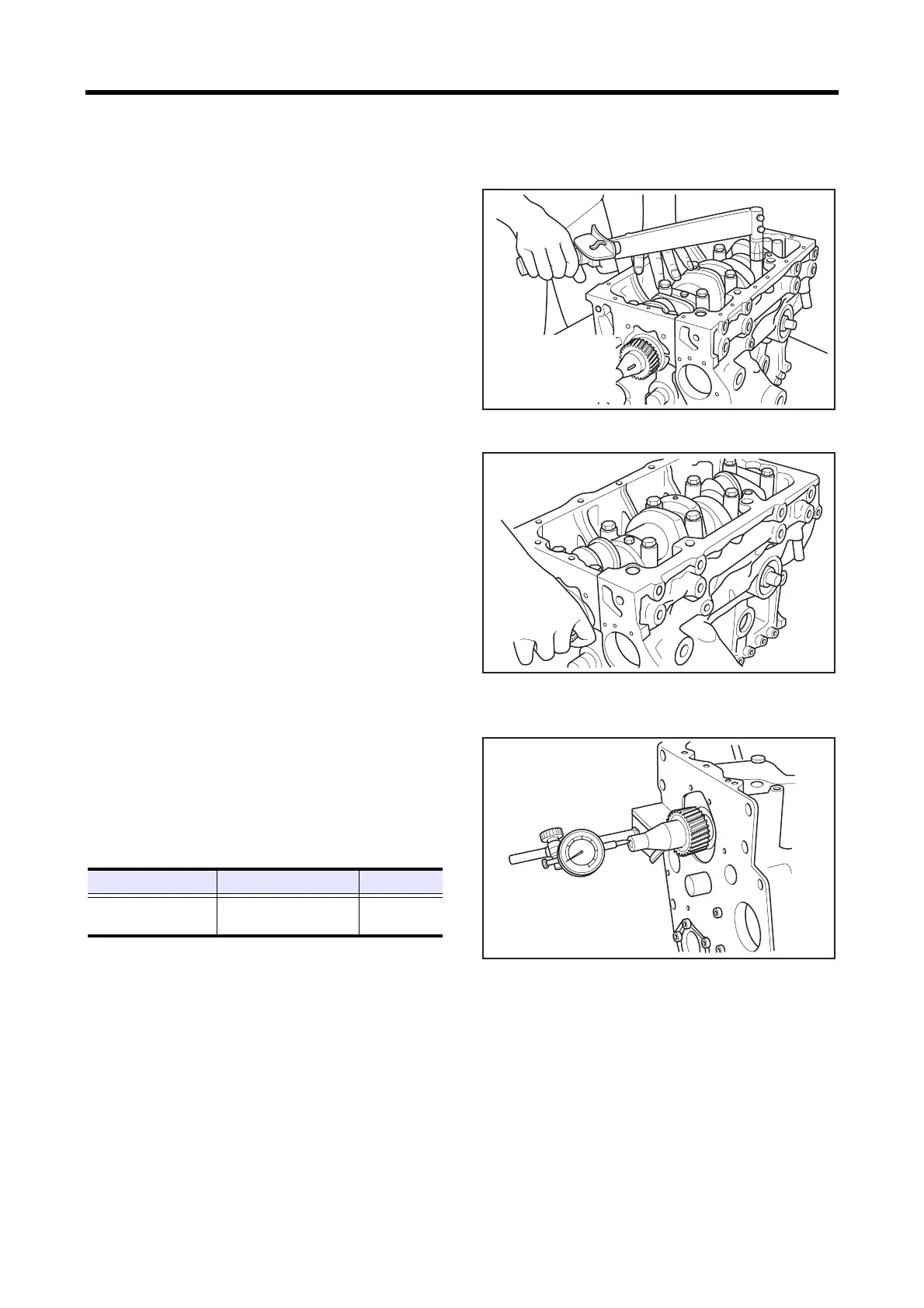

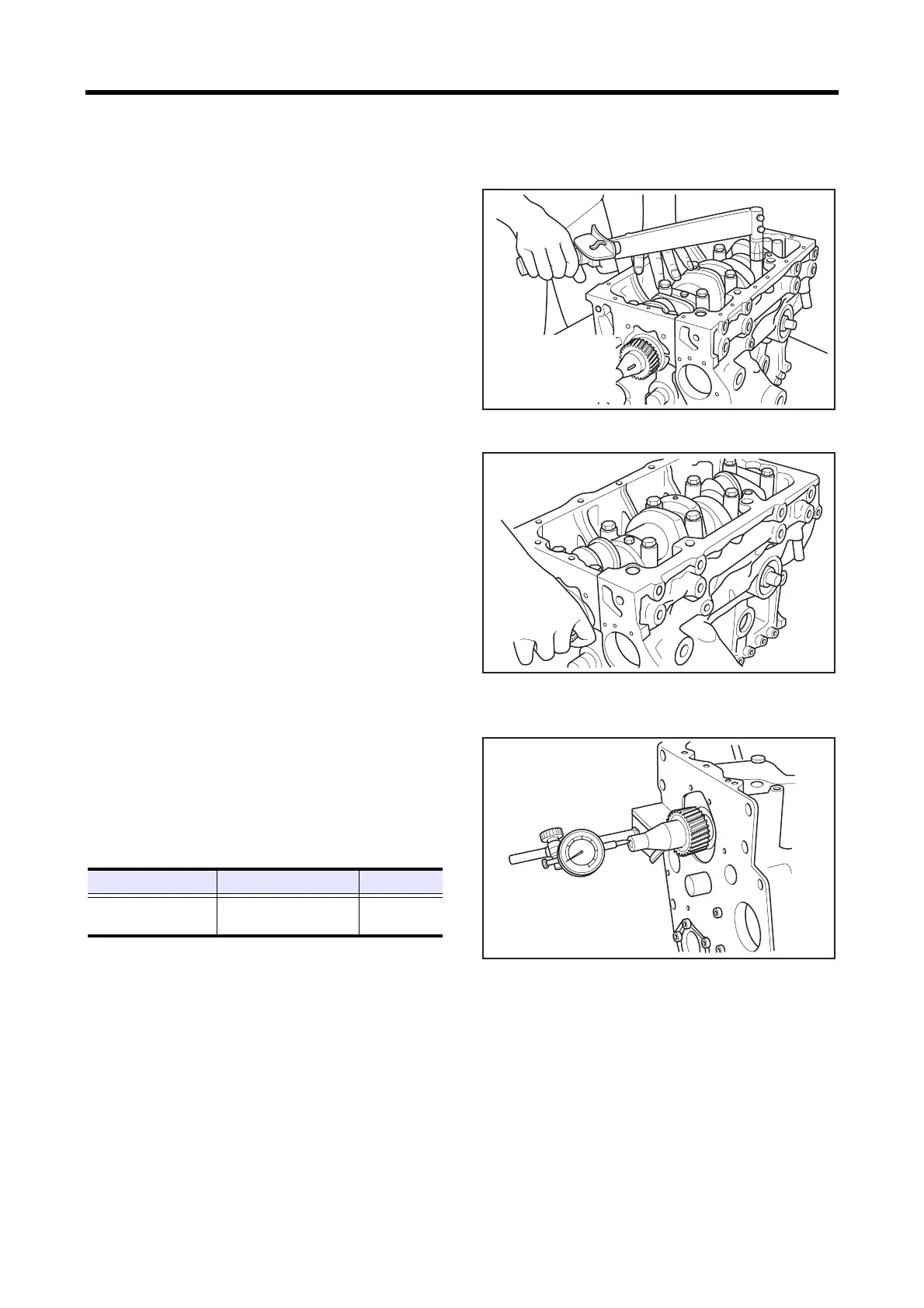

1.5 Installing main bearing cap bolt

(1)

Tighten the main bearing cap bolts alternately and

progressively to the specified torque.

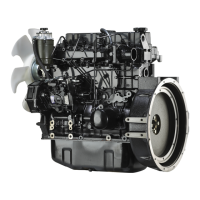

(2) Make sure that the crankshaft rotates smoothly.

Tightening main bearing cap bolt

Checking crankshaft for rotation

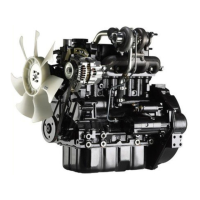

1.6 Measuring crankshaft end play

Attach a dial gauge to the end of the crankshaft to measure

the end play.

If the end play deviates from the standard value, loosen the

main bearing cap bolts and retighten.

Make sure that the camshaft turns freely.

Measuring crankshaft end play

49.0 to 53.9 N·m

{5.0 to 5.5 kgf·m}

[36.2 to 39.8 lbf·ft]

Item Standard Limit

Measuring crankshaft

end play

0.050 to 0.175 mm

[0.0020 to 0.0069 in.]

0.500 mm

[0.0197 in.]

Loading...

Loading...