VBA20001-R.3720.A

- A 12 ・ -

logo�Q0310�forGraphic

070509�Gdesign�ito

<

Device

>

1. For Main mirror adjustment

①

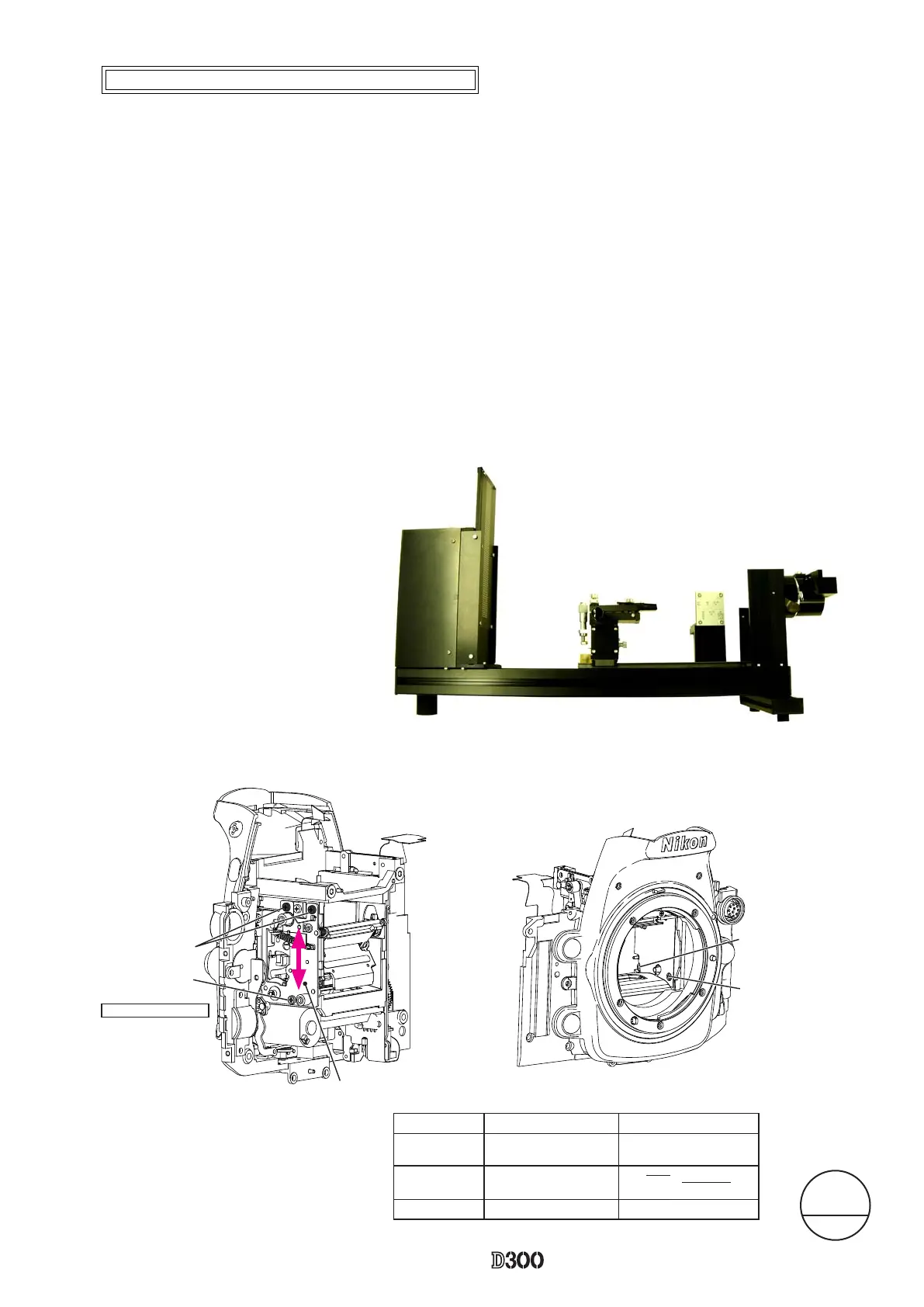

Mirror angle inspection tool

②

45° angle mirror tool

③

Hexagonal wrench (φ1.5mm

)

2. For sub-mirror adjustment

①

Mirror angle inspection tool

②

Hexagonal wrench (φ1.5mm

)

・

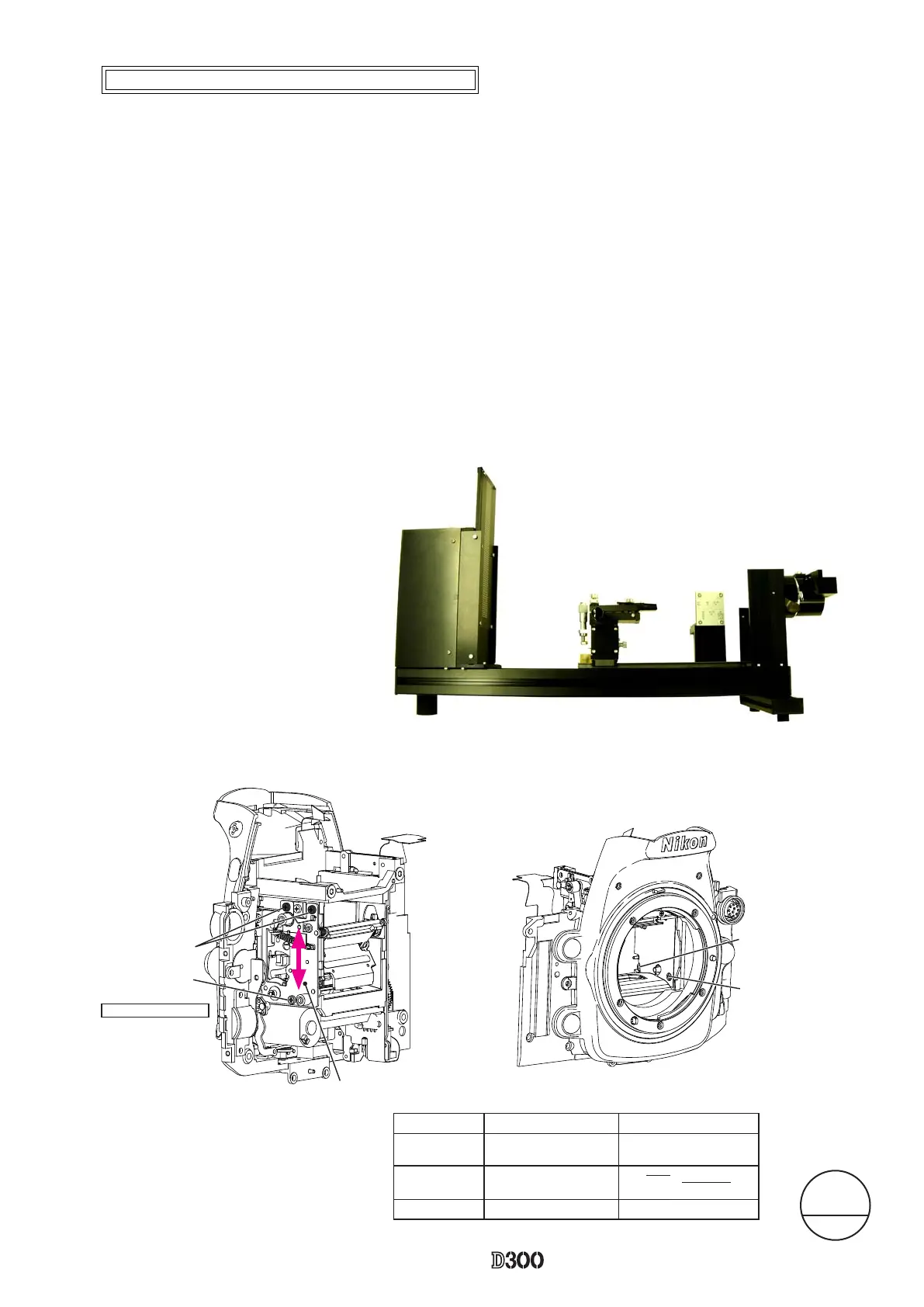

Main mirror 45° adjustment

Caution: Before and after the adjustment, check the accuracy by moving the main mirror up- and downwards a

few times.

①

Check for the right-left deviation

In case the result is out of standard, loose the two screws (#1523) and one screw (#1568), then make the

adjustment by moving the main mirror shaft PCB (#B10212).

②

Check for the up-down deviation.

In case the result is out of standard, make the adjustment by turning the eccentric pin.

・

Sub-mirror 59° adjustment

Caution: Before and after the adjustment, check the accuracy by moving the main mirror up- and downwards a

few times. Conrm if the two-pronged part of the sub-mirror rmly ts in the eccentric pin.

①

Check for the up-down deviation

In case the result is out of standard, make the adjustment by turning the sub-mirror eccentric pin.

Main mirror shaft base plate

#B10212

#1523×2

#1568

※

①

Mirror angle-inspection tool

Caution

:

Do NOT release the shutter.

Set the (supplied) tilted mirror with the main mirror being slightly lifted

so that the sub-mirror of D300 does not touch the (supplied) tilted

mirror of the inspection tool.

※

Procedure: Follow the operating instructions of the tool for main/sub mirror angle-inspection (J19132).

Main mirror

Sub-mirror

Left-right

deviation

±10’ -

Up-down

deviation

±5’ ±10’ -15±15’

Distortion

6’or less

6’or less

< Standard value >

Angle adjustment of Main mirror and sub-mirror

Apply after the

adjustment

Adhesive: Screwlock

Eccentric pin for the

sub-mirror

Eccentric pin for the

main mirror

Changed Page

△

×1 Feb.1st.2008

△(

Revision

)

Loading...

Loading...