44205401TH Rev.1

161 /

Oki Data CONFIDENTIAL

7. Troubleshooting and repair procedure

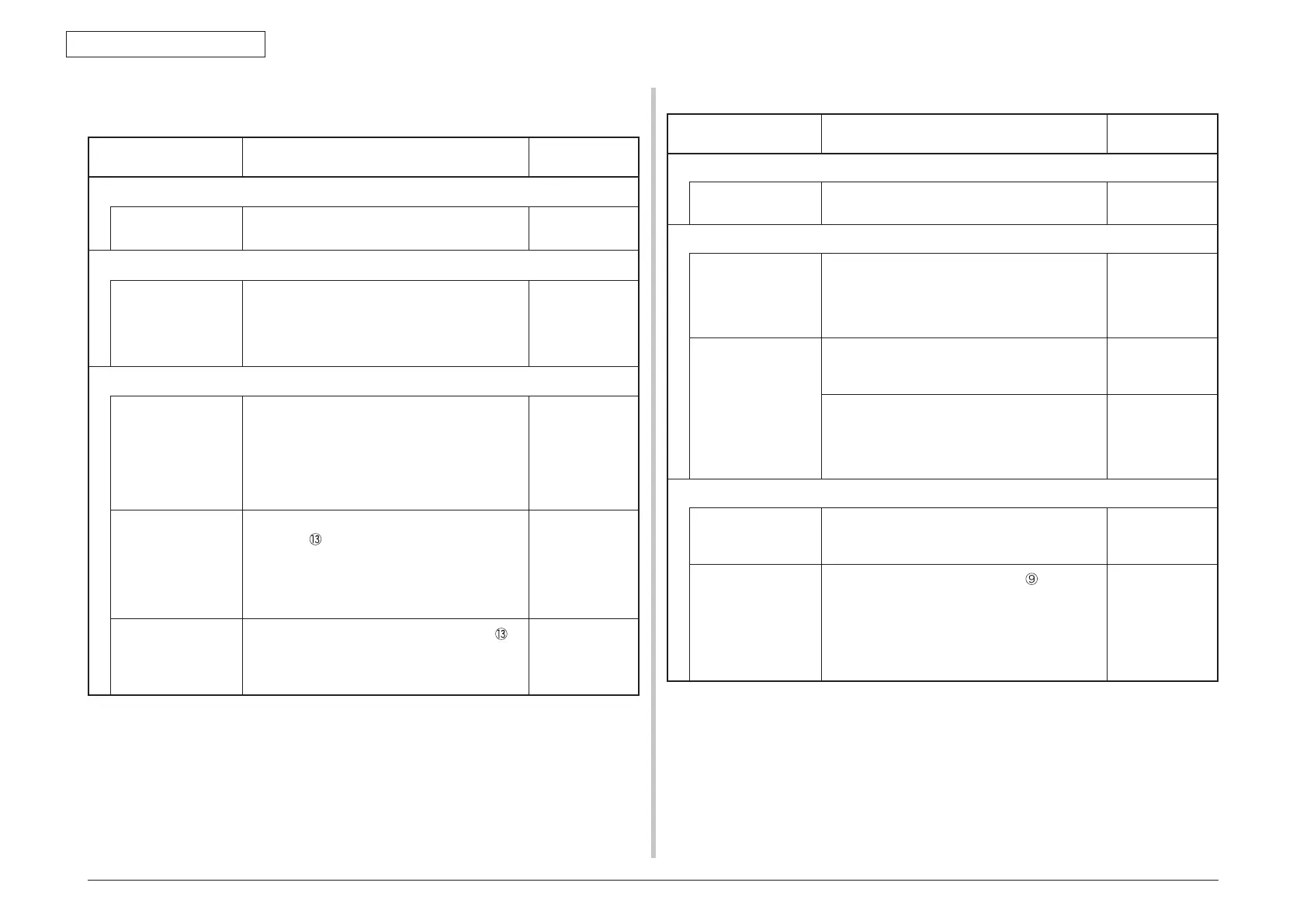

7.5.2. (3) Paper feed jam (error code 391: 1st tray)

(3-1) Jam occurs immediately after the power is turned on. (1st tray)

Check item Check work

Action to be taken

at NG

(3-1-1) Check condition of the paper running path

Paper running path

of the front unit

Open the front co

ver check if paper is not

jammed in the paper running path.

Remove the

jammed paper

.

(3-1-2) Check condition of the mechanical parts

Check the sensor

lev

ers of the paper

entrance sensor

1 and the paper

entrance sensor 2.

Check if shape and mov

ement of the sensor

levers have any abnormality or not.

Replace the

sensor lever with

the good sensor

lever.

(3-1-3) Check condition of electrical parts

Check the detection

condition of the

sensor signal.

Confirm that the sensor signals are normally

detected by using the Maintenance Menu

SWITCH SCAN function.

Replace either

the CU/PU board

or the front

sensor board

(RSF PCB)

or connection

cable.

Check output signal

level of the paper

entrance sensor 1

and that of the paper

entrance sensor 2.

Chec

k for the f

ollowing signals at the FSNS

connector of the CU/PU board.

Pin-4: Paper entrance sensor 1

Pin-3: Paper entrance sensor 2

Confirm that the above signal levels change

when the sensor lever is operated.

Replace the

front sensor

board (RSF

PCB)

Check the power

voltages supplied

to the front sensor

board (RSF PCB)

Check the 5V power at the FSNS connector

of the front sensor board (RSF PCB).

Pin-1: 5V power supply

Pin-5: 0VL

Replace the

connection

cable.

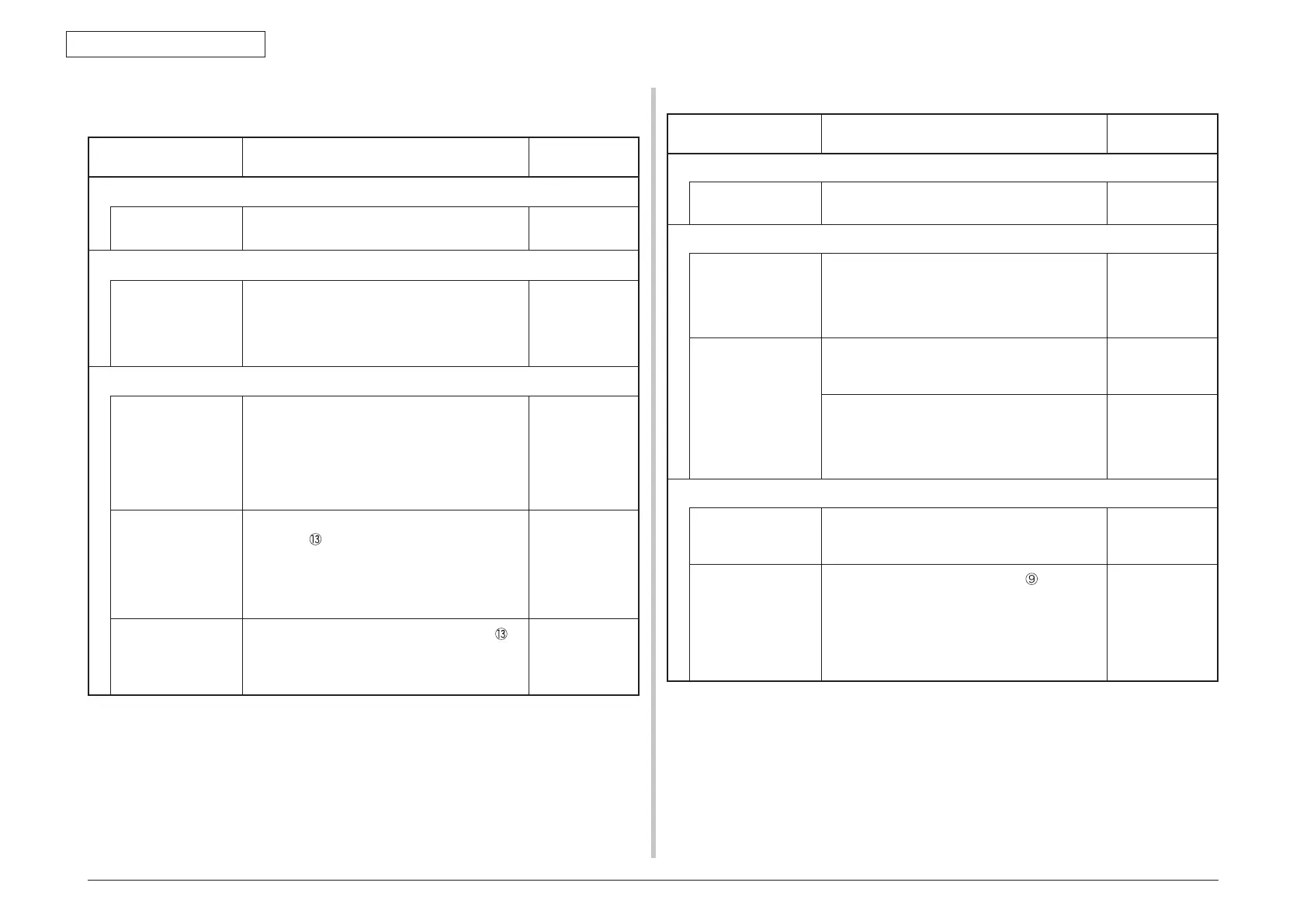

(3-2) Jam occurs immediately after the paper feed is started. (1st tray)

Check item Check work

Action to be taken

at NG

(3-2-1) Check condition of the paper running path

Paper running path

of the front unit

Check if paper is jammed or not in the paper

running path.

Remove the

jammed paper.

(3-2-2) Check condition of the mechanical parts

Check the sensor

levers of the paper

entrance sensor

1 and the paper

entrance sensor 2.

Check if shape and movement of the sensor

levers have any abnormality or not.

Replace the

sensor with the

good sensor

lever.

Check the separator

assemblies of the

feed roller, the

pickup roller and the

tray.

Check if any foreign materials such as paper

dust on the surface of the feed roller or of the

pickup roller or not.

Remove the

foreign material.

Check if the feed roller or the pickup roller has

worn out or not.

Replace the

separator

assemblies of the

feed roller, pickup

roller and tray.

(3-2-3) Motor operation check

Paper feed motor Confirm that the paper feed motor works

normally by using the Motor & Clutch Test of the

self-diagnostic mode.

Replace the CU/

PU board or the

paper feed motor.

Paper feed motor

driver

Remove the HP_PSZCL connector

of the

CU/PU board and check the followings at the

connector side.

Several M

Ω

between pin-1 – FG.

Several M

Ω

between pin-2 – FG.

Several M

Ω

between pin-3 – FG.

Several M

Ω

between pin-4 – FG.

Replace the

CU/PU board.

Loading...

Loading...