6-2

Periodic Maintenance

This section lists when to perform periodic maintenance on your robots and the steps for checking

each item to inspect.

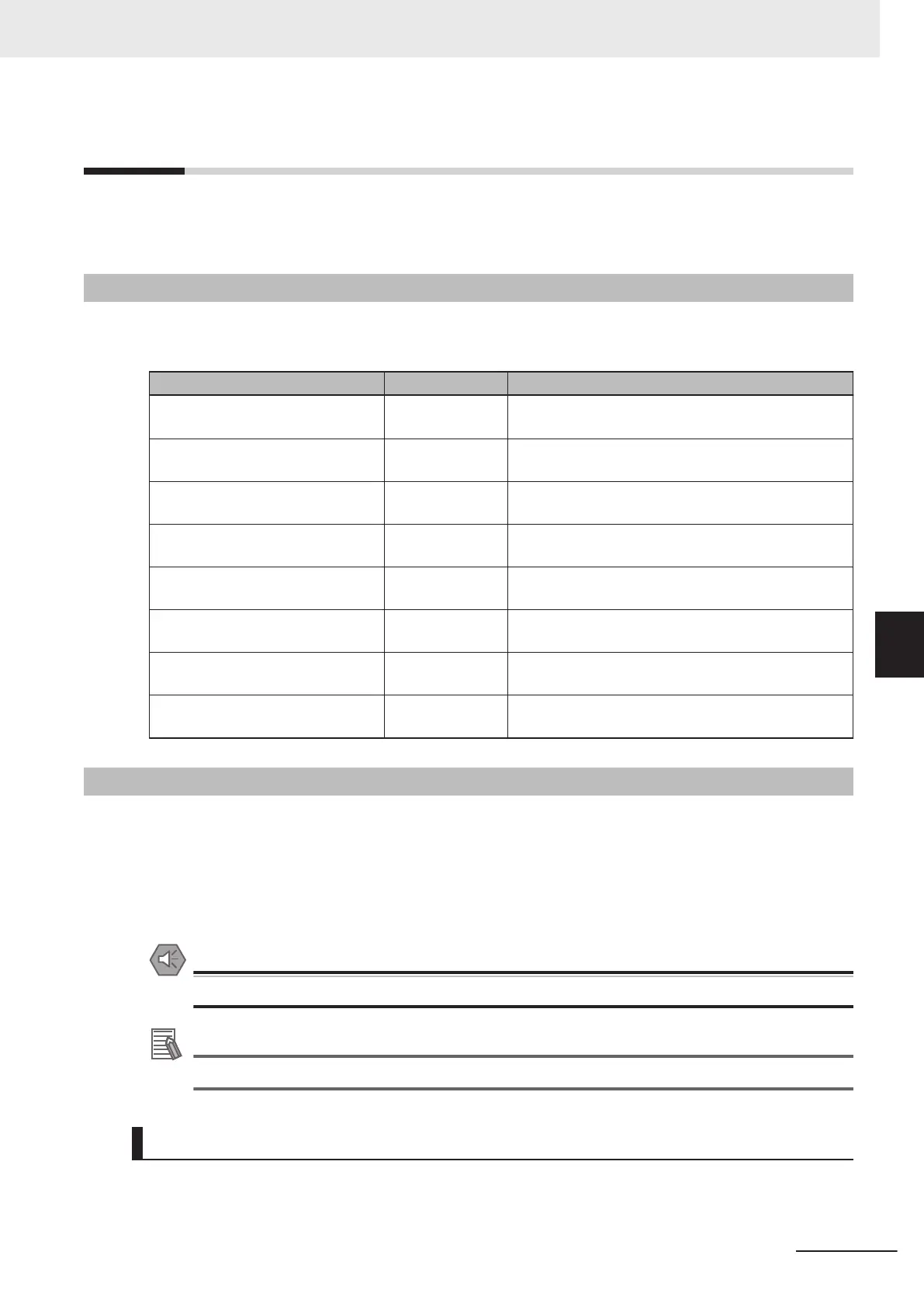

6-2-1

Periodic Maintenance Overview

The following table gives a summary of the periodic maintenance procedures and guidelines on fre-

quency.

Item Period Reference

Check E-Stop, enable and key

switches, and barrier interlocks

6 months Refer to 6-2-2 Checking Safety Functions on page

6-3 for more information.

Check fastener torques 3 months Refer to 6-2-3 Checking Fastener Torques on page

6-4 for more information.

Check safety labels 1 week Refer to 6-2-4 Checking Safety and Warning Labels

on page 6-4 for more information.

Check the High Power indicator op-

eration

1 week Refer to High Power Indicator Check Procedure on

page 3-32 for more information.

Check for signs of oil around robot

joints

3 months Refer to 6-2-5 Checking for Oil Leaks on page 6-5

for more information.

Lubricate the joint 3 quill 3 months or 150

km of travel

Refer to 6-2-6 Lubricating Joint 3 on page 6-6 for

more information.

Replace the encoder backup bat-

teries

2 to 4 years Refer to 6-2-7 Replacing Encoder Backup Batteries

on page 6-7 for more information.

Clean the exterior of the robot As needed Refer to 6-2-8 Cleaning the Robot on page 6-8 for

more information.

6-2-2

Checking Safety Functions

All safety devices in the system should be checked regularly for proper functionality. Operating any of

the following safety devices should disable robot High Power.

• E-stop button(s) on the Front Panel or connected to the XSYSTEM cable.

• E-stop button and enabling switch on the pendant (if present).

• All other safety devices connected to the XSYSTEM cable.

Precautions for Safe Use

The High Power indicator must be operational to satisfy safety requirements.

Additional Information

Refer to 3-10-3 Safety Equipment Checks on page 3-31 for more information.

High Power Indicator Check

The robot monitors current used by the High Power indicator. This is to ensure that a High Power indi-

cator device is connected and functioning properly to satisfy safety requirements.

6 Maintenance

6-3

i4L Robots User's Manual (I658)

6-2 Periodic Maintenance

6

6-2-1 Periodic Maintenance Overview

Loading...

Loading...